Preparation method for double-rare earth element lanthanum and gadolinium codoped titanium dioxide nanotube

A technology of titanium dioxide and nanotubes, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as low photocatalytic quantum efficiency, low solar energy utilization rate, and narrow adsorption range. Achieve the effects of simple preparation process, convenient and simple product treatment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present invention adopts impregnation-co-precipitation method to prepare double rare earth-doped titanium dioxide nanotube composite material, and the method comprises the following steps:

[0030] (1) TiO 2 Preparation of nanotubes: Preparation of TiO by a strong alkali-hydrothermal method 2 nanotube;

[0031] (2) configure lanthanum nitrate and gadolinium nitrate aqueous solution (0.001M);

[0032] (3) During the stirring process, weigh a certain amount of TiO 2 Nanotube (0.01M) in the solution of step (2); Continue stirring for 16h;

[0033] (4) the product is suction filtered and washed (removing surface-adsorbed La 3+ and Gd 3+ ), the resulting product was dried in a constant temperature oven at 80°C for 10 h, and ground into powder to obtain La and Gd co-doped TiO 2 nanotube composites.

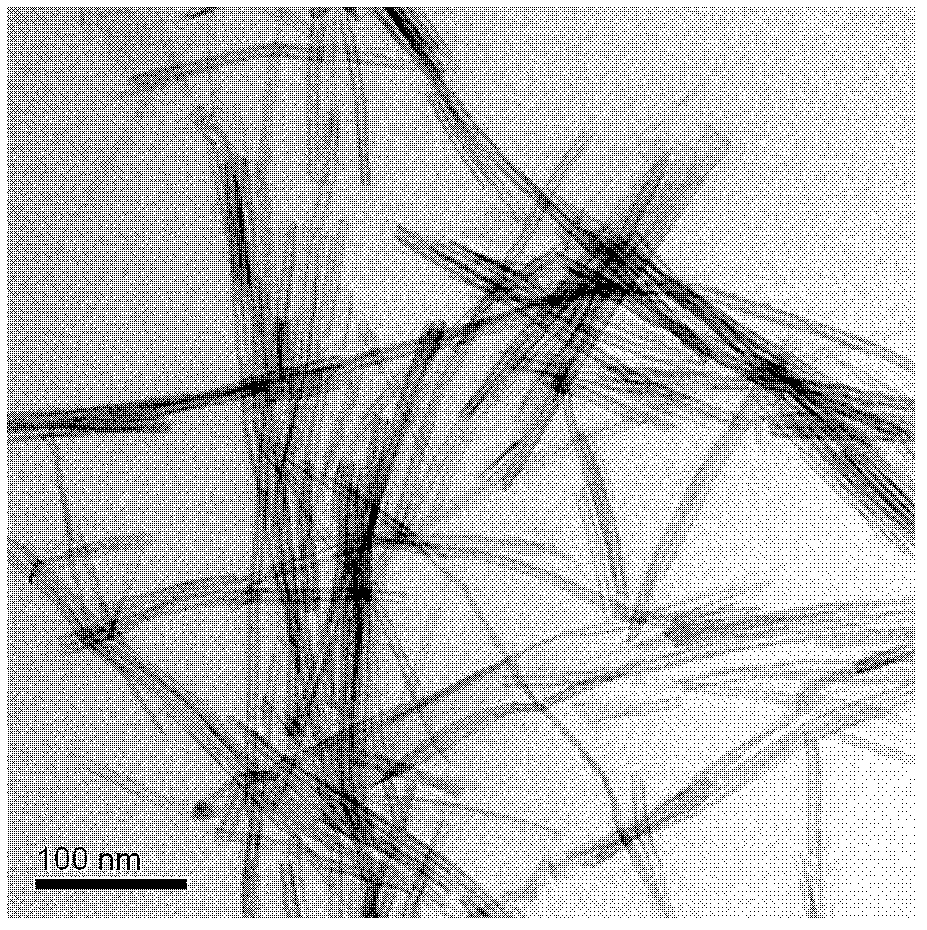

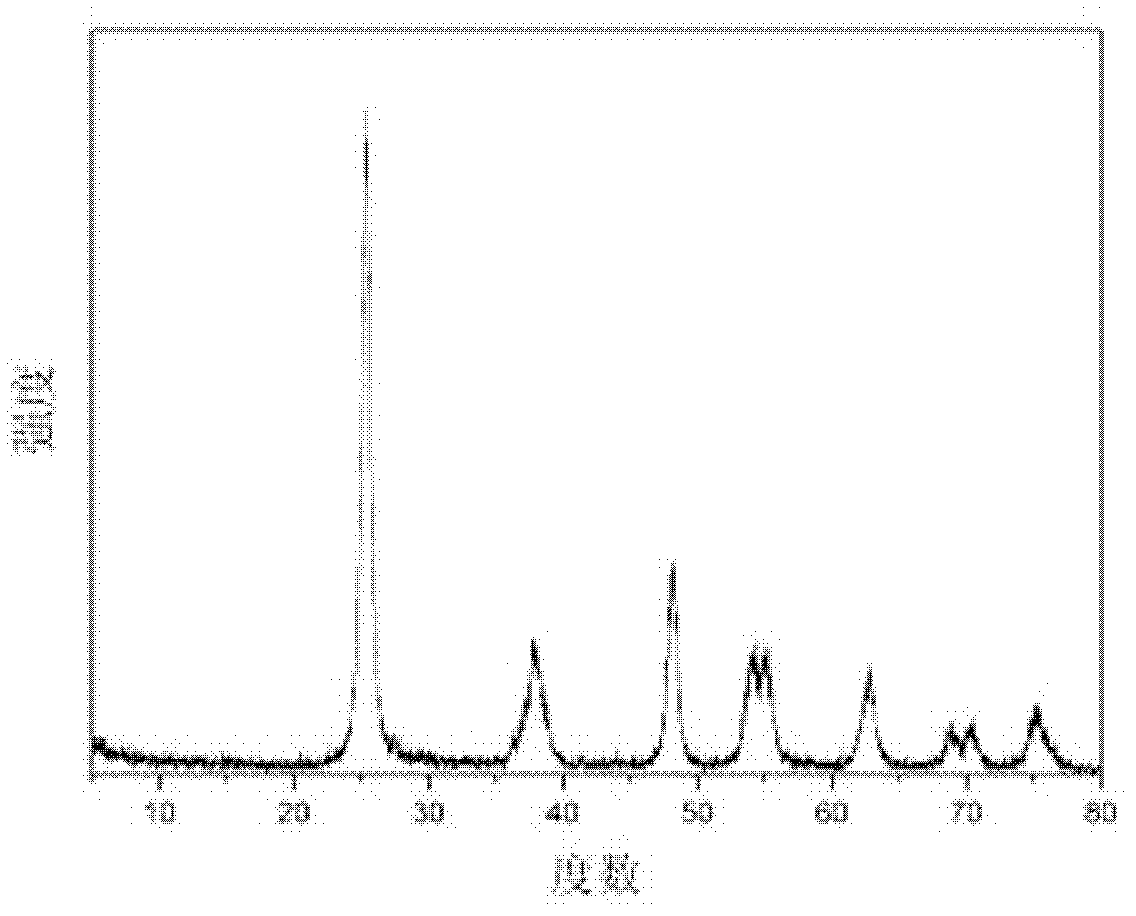

[0034] The product obtained in step (4) is characterized by TEM and XRD for its structure and crystal form respectively, figure 1 , 2 TiO prepared by strong alkali m...

Embodiment 2

[0036] The present invention adopts impregnation-co-precipitation method to prepare double rare earth-doped titanium dioxide nanotube composite material, and the method comprises the following steps:

[0037] (5)TiO 2 Preparation of nanotubes: Preparation of TiO by a strong alkali-hydrothermal method 2 nanotube;

[0038] (6) configure lanthanum nitrate and gadolinium nitrate aqueous solution (0.001M);

[0039] (7) During the stirring process, weigh a certain amount of TiO 2 Nanotube (0.01M) in the solution of step (2); Continue stirring for 16h;

[0040] (8) Suction filtration of the product, washing (removing surface-adsorbed La 3+ and Gd 3+ ), the resulting product was dried in a constant temperature oven at 80 °C for 10 h, ground into powder, and finally placed in a muffle furnace for calcination at 300 °C to obtain La and Gd co-doped TiO 2 nanotube composites.

Embodiment 3

[0042] The present invention adopts impregnation-co-precipitation method to prepare double rare earth-doped titanium dioxide nanotube composite material, and the method comprises the following steps:

[0043] (1) TiO 2 Preparation of nanotubes: Preparation of TiO by a strong alkali-hydrothermal method 2 nanotube;

[0044] (2) configure lanthanum nitrate and gadolinium nitrate aqueous solution (0.001M);

[0045] (3) During the stirring process, weigh a certain amount of TiO 2 Nanotube (0.01M) in the solution of step (2); Continue stirring for 16h;

[0046] (4) the product is suction filtered and washed (removing surface-adsorbed La 3+ and Gd 3+ ), the resulting product was dried in a constant temperature oven at 80 °C for 10 h, ground into powder, and finally placed in a muffle furnace for calcination at 400 °C to obtain La and Gd co-doped TiO 2 nanotube composites.

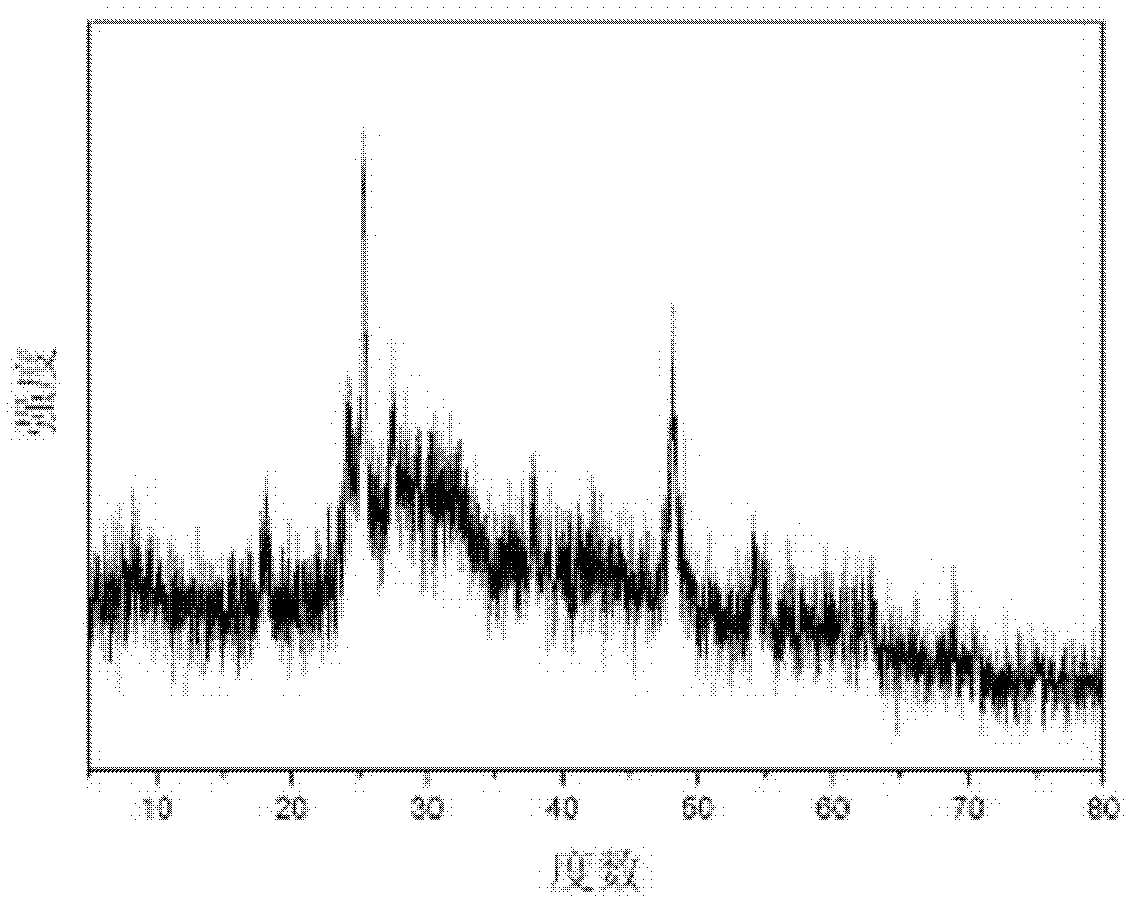

[0047] The product obtained in step (4) is characterized by TEM, as Figure 5 As shown, it can be seen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com