Graded mixed crystal TiO2 micro-nanomaterial, preparation method and application of micro-nanomaterial

A micro-nano, mixed crystal technology, applied in the field of photocatalysis, to achieve mild reaction conditions, environmental friendliness, and good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Add 0.04mol / L tetrabutyl titanate dropwise to a mixed solution of 50mL ethanol and 80mL water, mix well, and obtain a sol after standing for 10 hours;

[0057] (2) Condensate the sol in step (1) with 0.4mol / L hydrochloric acid in an oil bath at 100°C for 22 hours to obtain a white emulsion;

[0058] (3) centrifuging the white emulsion in step (2), washing and drying in an oven, and calcining in a muffle furnace at 300°C;

[0059] (4) Disperse the white powder in step (3) in 7mol / L NaOH aqueous solution, and place it in a reaction kettle for hydrothermal reaction at 150°C for 5 hours;

[0060] (5) After the reaction is completed, the obtained white precipitate is centrifuged, washed to a pH value of 7, and then dried to obtain graded mixed crystal TiO 2 micro-nano materials.

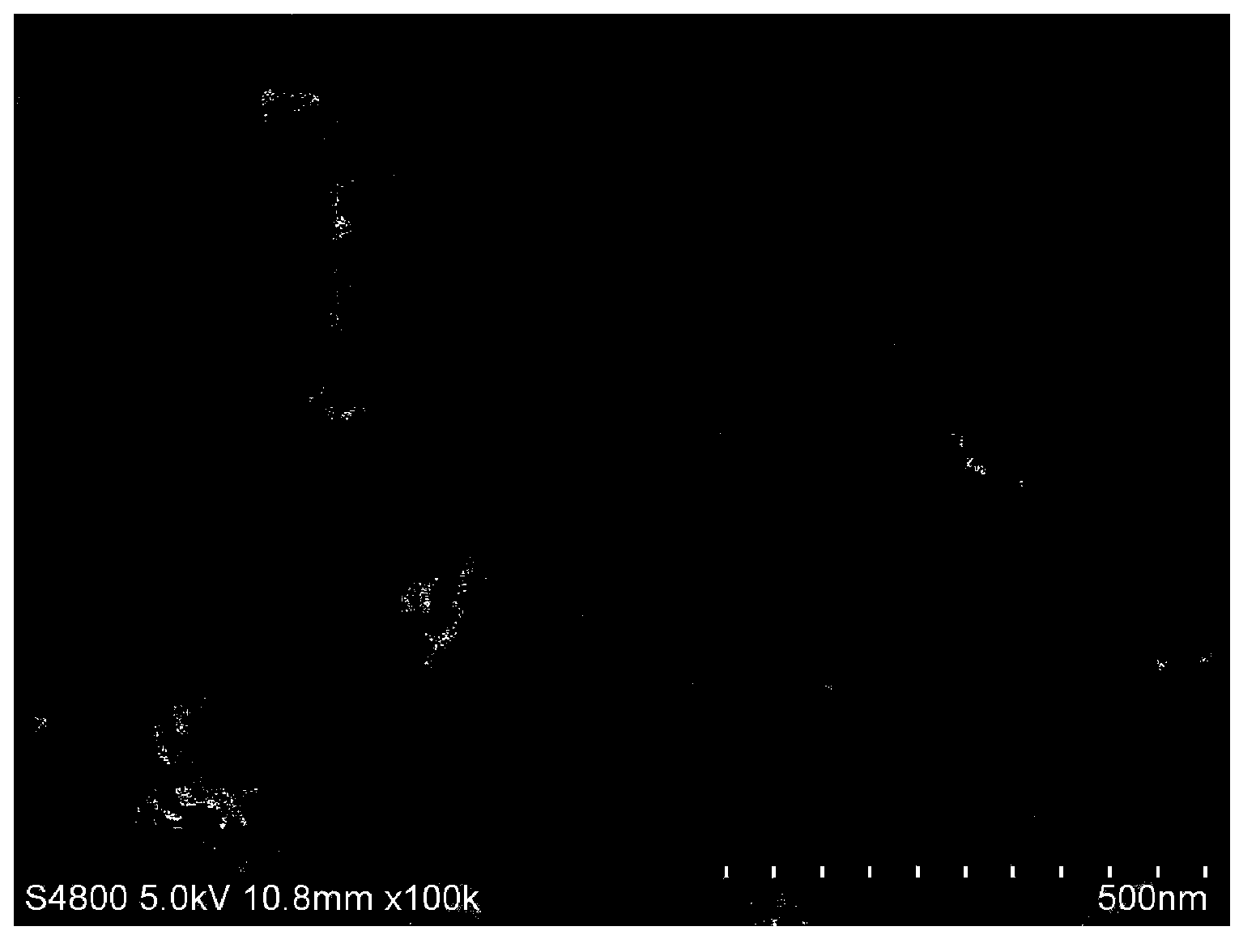

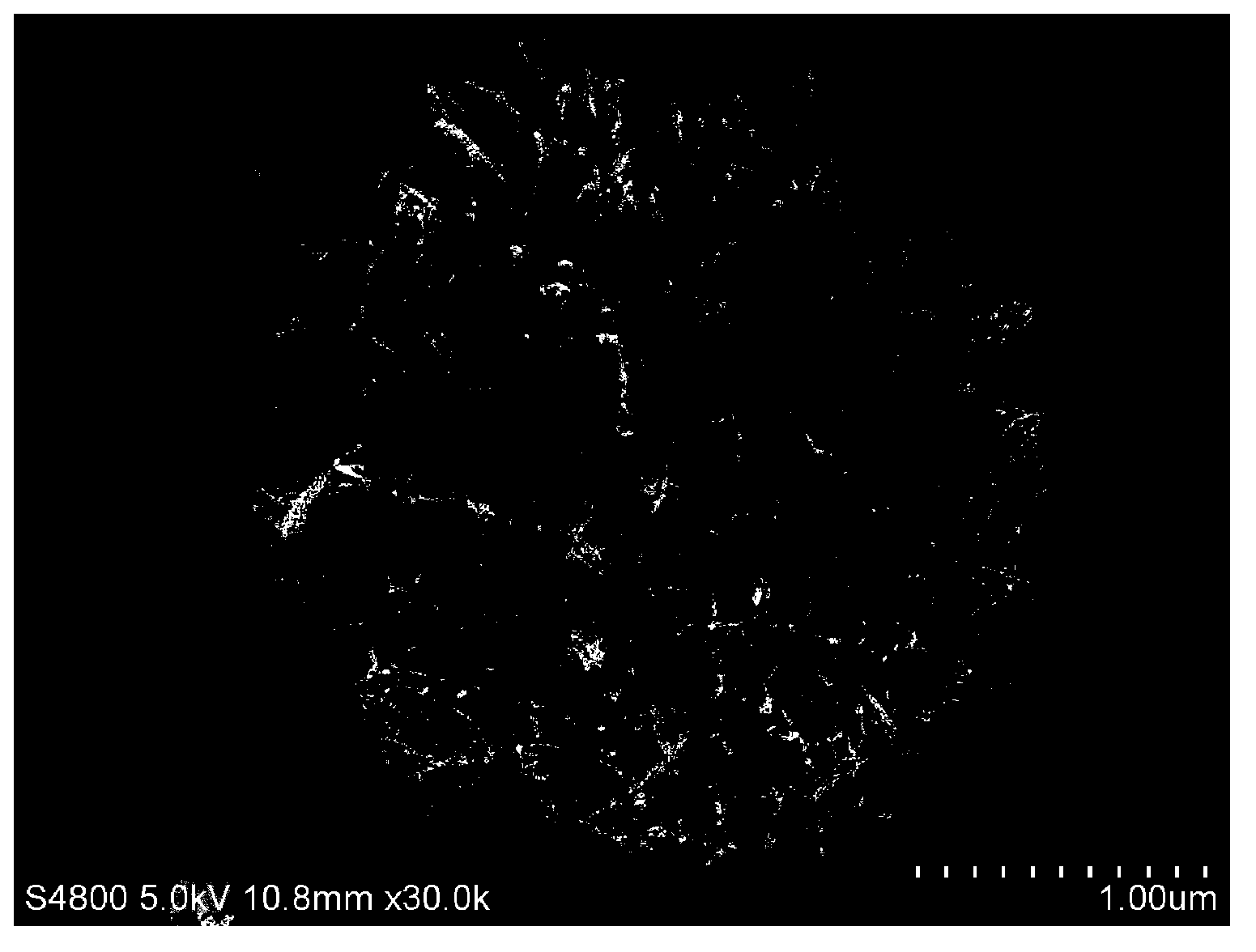

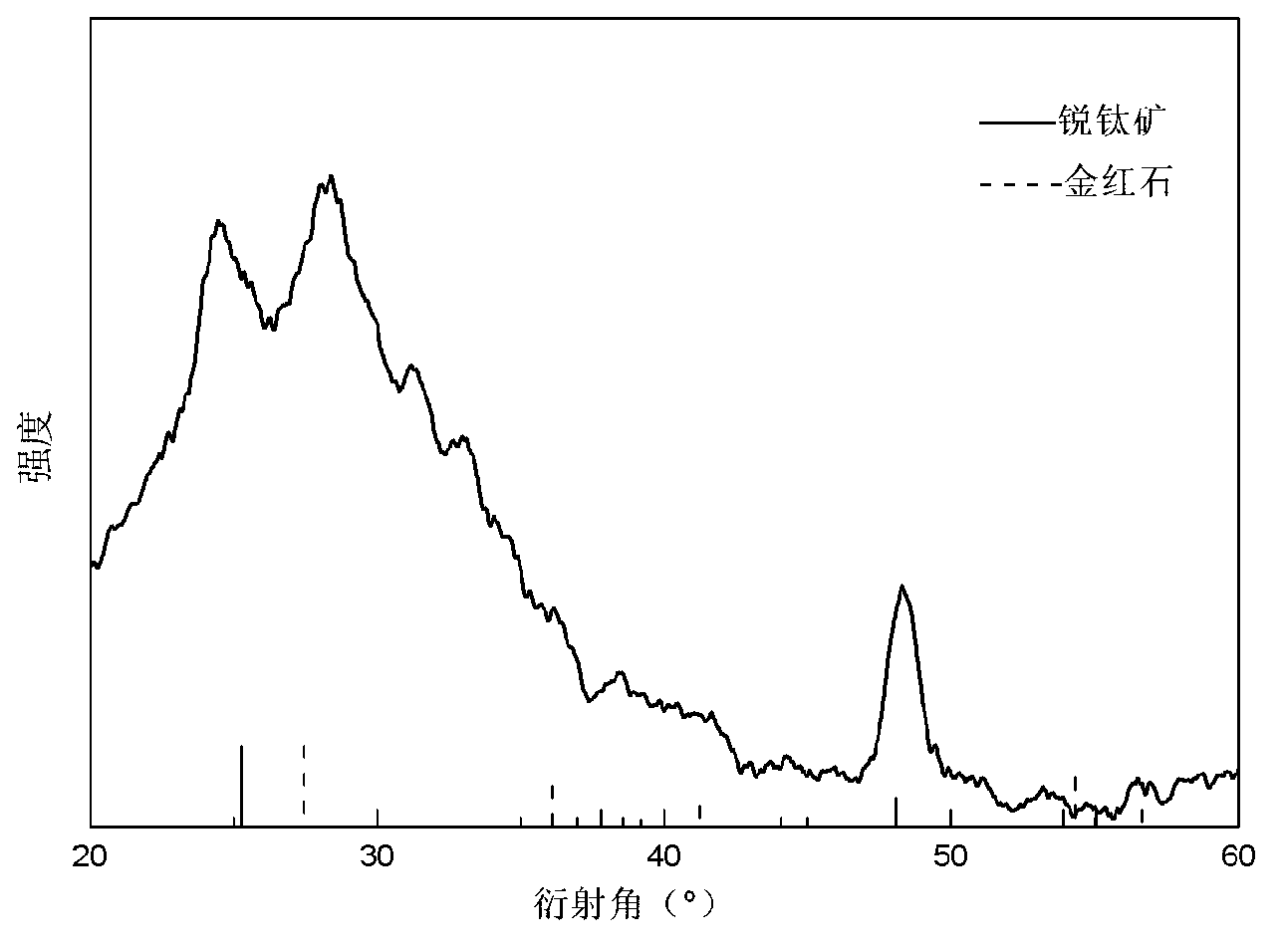

[0061] figure 1 , figure 2 Shown is the graded mixed crystal TiO prepared in Example 1 2 SEM images of micro-nano materials at different magnifications. It can be seen from the figure tha...

Embodiment 2

[0063] (1) Add 0.04mol / L tetrabutyl titanate dropwise to a mixed solution of 50mL ethanol and 80mL water, mix well, and obtain a sol after standing for 10 hours;

[0064] (2) Condensate the sol of step (1) and 0.5mol / L hydrochloric acid in an oil bath at 100°C for 22 hours to obtain a white emulsion;

[0065] (3) centrifuging the white emulsion in step (2), washing and drying in an oven, and calcining in a muffle furnace at 300°C;

[0066] (4) Disperse the white powder in step (3) in 7mol / L NaOH aqueous solution, and place it in a reaction kettle for hydrothermal reaction at 150°C for 5 hours;

[0067] (5) After the reaction is completed, the obtained white precipitate is centrifuged, washed to a pH value of 7, and then dried to obtain graded mixed crystal TiO 2 micro-nano materials.

[0068] Figure 5 Shown is the graded mixed crystal TiO prepared in Example 2 2 The SEM image of the micro-nano material, it can be seen from the figure that the diameter of the flower-shaped...

Embodiment 3

[0070] (1) Add 0.04mol / L tetrabutyl titanate dropwise to a mixed solution of 50mL ethanol and 50mL water, mix well, and obtain a sol after standing for 12 hours;

[0071] (2) Condensate the sol in step (1) with 0.4mol / L hydrochloric acid in an oil bath at 100°C for 24 hours to obtain a white emulsion;

[0072] (3) centrifuging the white emulsion in step (2), washing and drying in an oven, and calcining in a muffle furnace at 300°C;

[0073] (4) Disperse the white powder in step (3) in 7mol / L NaOH aqueous solution, and place it in a reaction kettle for hydrothermal reaction at 150°C for 5 hours;

[0074] (5) After the reaction is completed, the obtained white precipitate is centrifuged, washed to a pH value of 7, and then dried to obtain graded mixed crystal TiO 2 micro-nano materials.

[0075] The SEM image shows that the diameter of the flower-shaped microsphere is about 3 μm, and it is composed of a nanowire basic structure. The diameter of the nanowire is about 15 nm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com