Anti-forgery printing ink and manufacturing method thereof

A technology of anti-counterfeiting ink and manufacturing method, which is applied in the direction of ink, household utensils, applications, etc., can solve the problems of increasing equipment investment, effort, labor, etc., and achieve the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

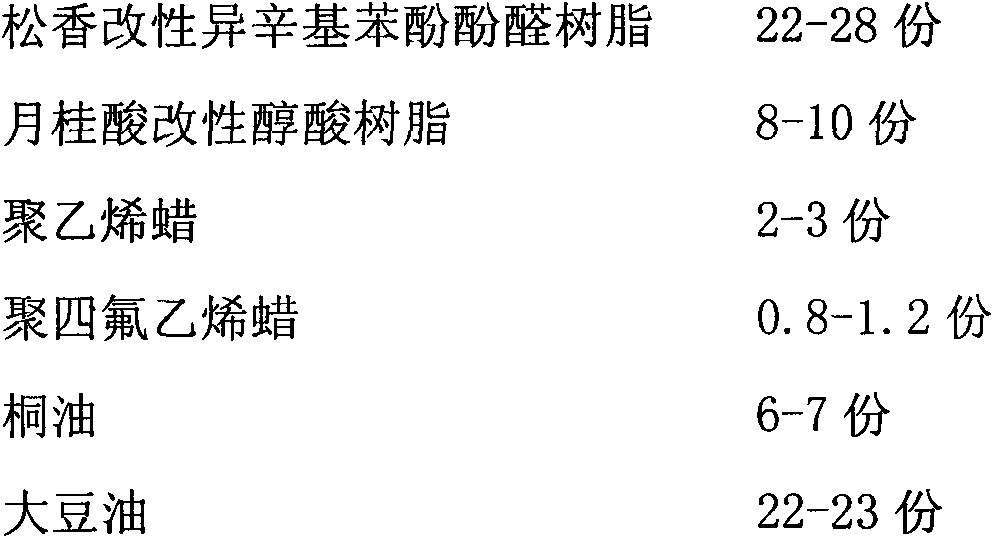

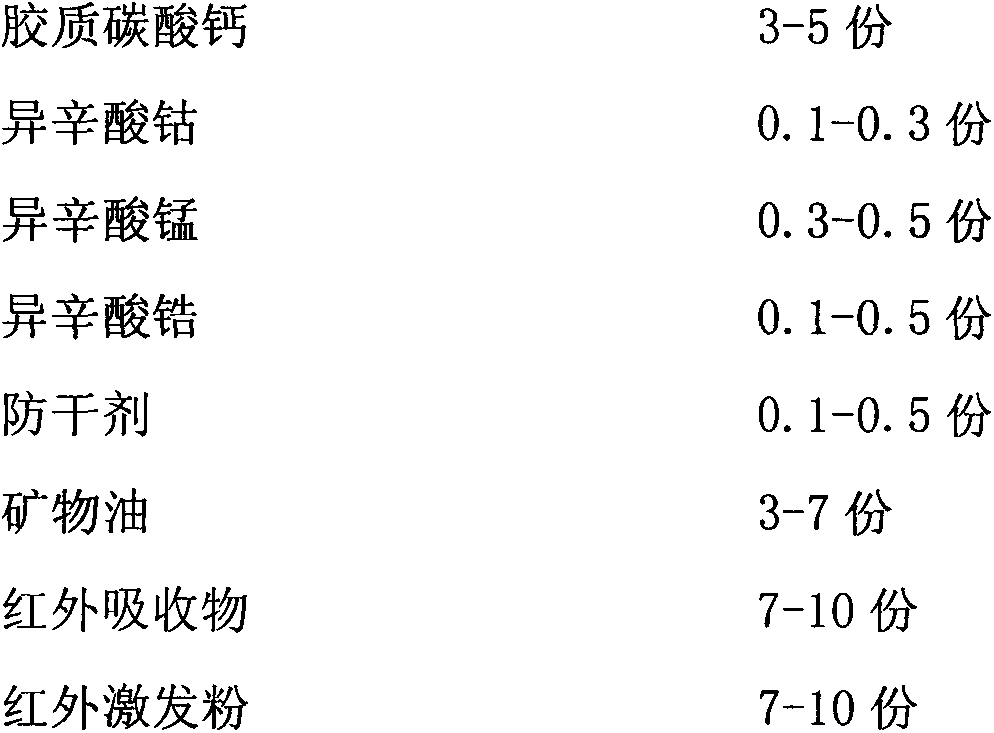

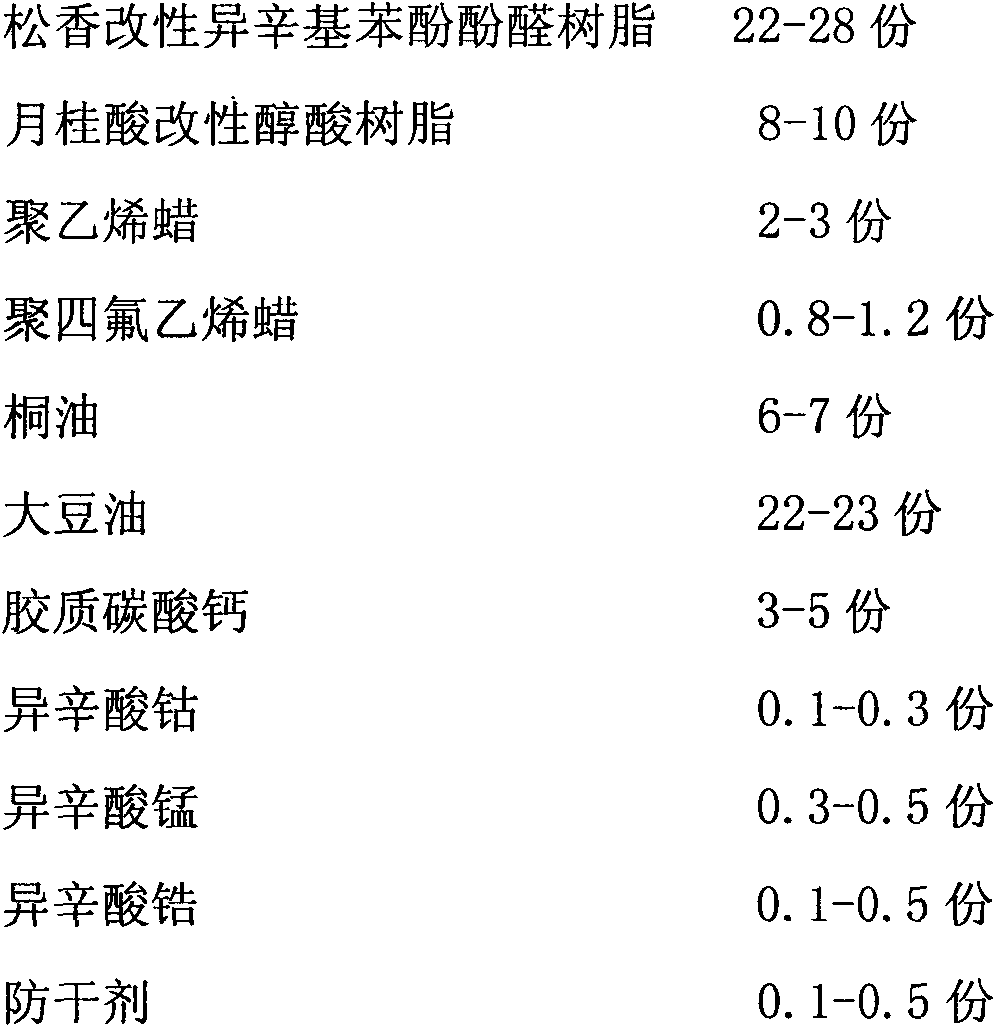

[0019] A kind of anti-counterfeiting ink of the present invention, according to parts by weight, it comprises the following components:

[0020]

[0021]

[0022] Among them: the anti-drying agent is butyraldehyde oxime or butanone oxime; the infrared absorbing substance is a mixture of one or more of phthalocyanine naphthalocyanine, aromatic amine or methine dye; or the infrared absorbing substance is calculated by weight percentage : 65-80% silicon carbide powder, 15-30% quartz powder and 1-8% zirconia; or the infrared absorbing material is 65-80% silicon carbide powder, 15-30% quartz powder and 1- 8% titanium oxide, the infrared excitation powder is the infrared excitation powder manufactured by Guangzhou Baoli'an Anti-counterfeiting Technology Co., Ltd.

[0023] The manufacture method of anti-counterfeiting ink of the present invention, it comprises the following steps:

[0024] (1) Mix 7-10 parts of infrared absorbing substance with 1-4 parts of mineral oil at a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com