Panchromatic fluorescent powder for white LED and preparation method of panchromatic fluorescent powder

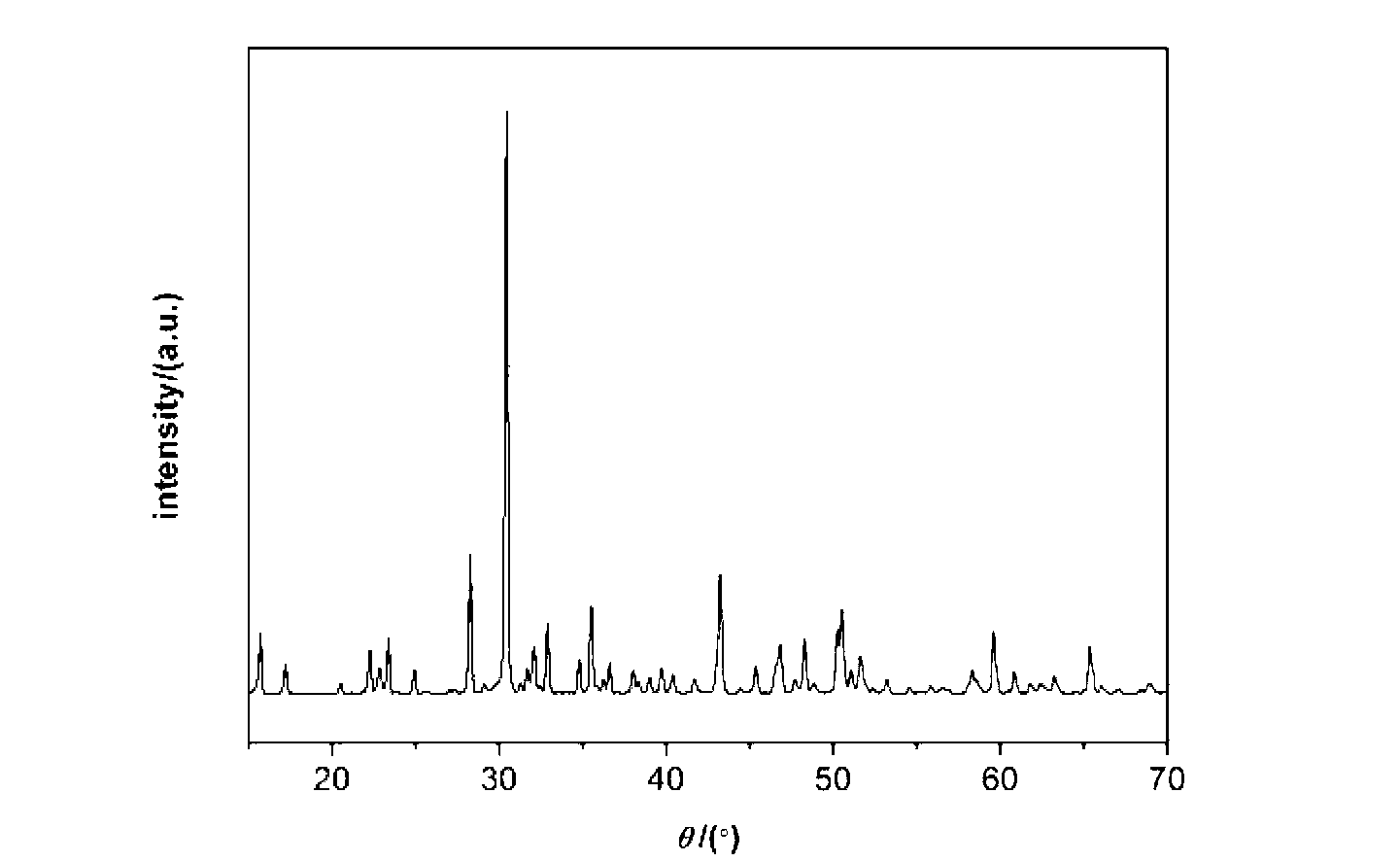

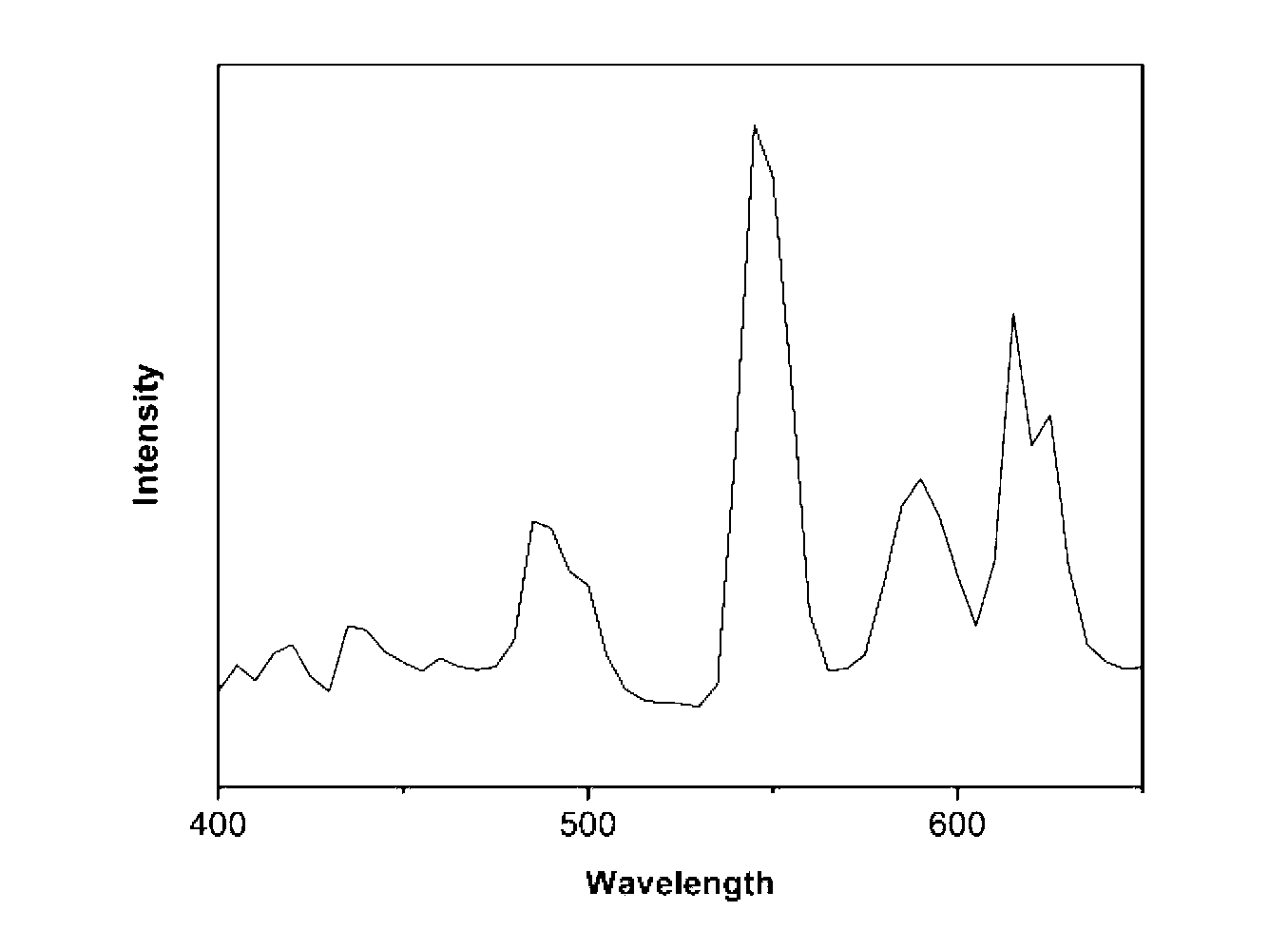

A phosphor and full-color technology, applied in the field of full-color phosphors for white light LEDs and their preparation, can solve the problem that excited ions are difficult to emit white light, and achieve a simple and convenient preparation process, low synthesis cost, and good crystal development. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) First follow 0.02mol of Sr 1.995 MgSi 2 o 7 :0.005Tb 3+ Weigh 0.00005mol of Tb with the content of Tb 4 o 7 , Tb 4 o 7 commercially available Tb 4 o 7 , with a purity of 99.99%, put it in a beaker, add nitric acid solution with a mass concentration of 56-58% into the beaker, stir continuously in a water bath at 60-80°C to dissolve it completely, add deionized water, and make Tb 3+ The molar concentration of 0.01mol / L is recorded as solution A.

[0031] 2) According to 0.02mol of Sr 1.995 MgSi 2 o 7 :0.005Tb 3+ Weigh analytically pure Sr(NO 3 ) 2 0.0399mol, Mg(N0 3 ) 2 ·6H 2 O0.02mol, H 3 BO 3 0.002mol and 0.1mol of urea were added to solution A, stirred thoroughly to dissolve, and solution B was obtained.

[0032]3) Measure Si(OC 2 h 5 ) 4 and absolute ethanol each 4.5mL, the Si(OC 2 h 5 ) 4 Added to absolute ethanol to obtain solution C.

[0033] 4) Slowly add solution C to solution B, stir well, adjust the pH value to 2~3, put it in a wat...

Embodiment 2

[0038] 1) First follow 0.02mol of Sr 1.99 MgSi 2 o 7 :0.01Tb 3+ Weigh 0.0001mol of Tb with the content of Tb 4 o 7 , put it in a beaker, add nitric acid solution with a mass concentration of 56-58% into the beaker, and stir continuously in a water bath at 60-80°C to dissolve it completely. Add deionized water to make Tb 3+ The molar concentration of 0.01mol / L is recorded as solution A.

[0039] 2) According to 0.02mol of Sr 1.99 MgSi 2 o 7 : 0.01 Tb 3+ Weigh Sr(NO 3 ) 2 0.0398mol, Mg(N0 3 ) 2 ·6H 2 O0.02mol, H 3 BO 3 0.002mol and 0.1mol of urea were added to solution A, stirred thoroughly to dissolve, and solution B was obtained.

[0040] 3) Measure Si(OC 2 h 5 ) 4 and absolute ethanol each 4.5mL, the Si(OC 2 h 5 ) 4 Added to absolute ethanol to obtain solution C.

[0041] 4) Slowly add solution C to solution B, stir well, adjust the pH value to 2~3, put it in a water bath at 60°C, take it out from the water bath when a light brown sol is formed, and c...

Embodiment 3

[0046] 1) First follow 0.02mol of Sr 1.95 MgSi 2 o 7 :0.05Tb 3+ Weigh 0.0005mol of Tb with the content of Tb 4 o 7 , put it in a beaker, add nitric acid solution with a mass concentration of 56-58% into the beaker, and stir continuously in a water bath at 70°C to dissolve it completely. Add deionized water to make Tb 3+ The molar concentration of 0.02mol / L is recorded as solution A.

[0047] 2) According to 0.02mol of Sr 1.95 MgSi 2 o 7 :0.05Tb 3+ Weigh Sr(NO 3 ) 2 0.039mol, Mg(N0 3 ) 2 ·6H 2 O0.02mol, H 3 BO 3 0.002mol and 0.4mol of urea were added to solution A, stirred thoroughly to dissolve, and solution B was obtained.

[0048] 3) Measure Si(OC 2 h 5 ) 4 4.5mL, absolute ethanol 6mL, Si(OC 2 h 5 ) 4 Added to absolute ethanol to obtain solution C.

[0049] 4) Slowly add solution C to solution B, stir well, adjust the pH value to 2~3, in a water bath at 70°C, take it out of the water bath when a light brown sol is formed, and cool it down.

[0050] 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com