Terahertz pulse measurement-based burning temperature sensing device and method

A technology of terahertz pulse and combustion temperature, which is applied to measuring devices, thermometers with physical/chemical changes, thermometers, etc., can solve the problems of unable to track the temperature of the measurement response, unable to understand the real situation of the burning object, and the disturbance of the measured object, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail below in conjunction with the accompanying drawings.

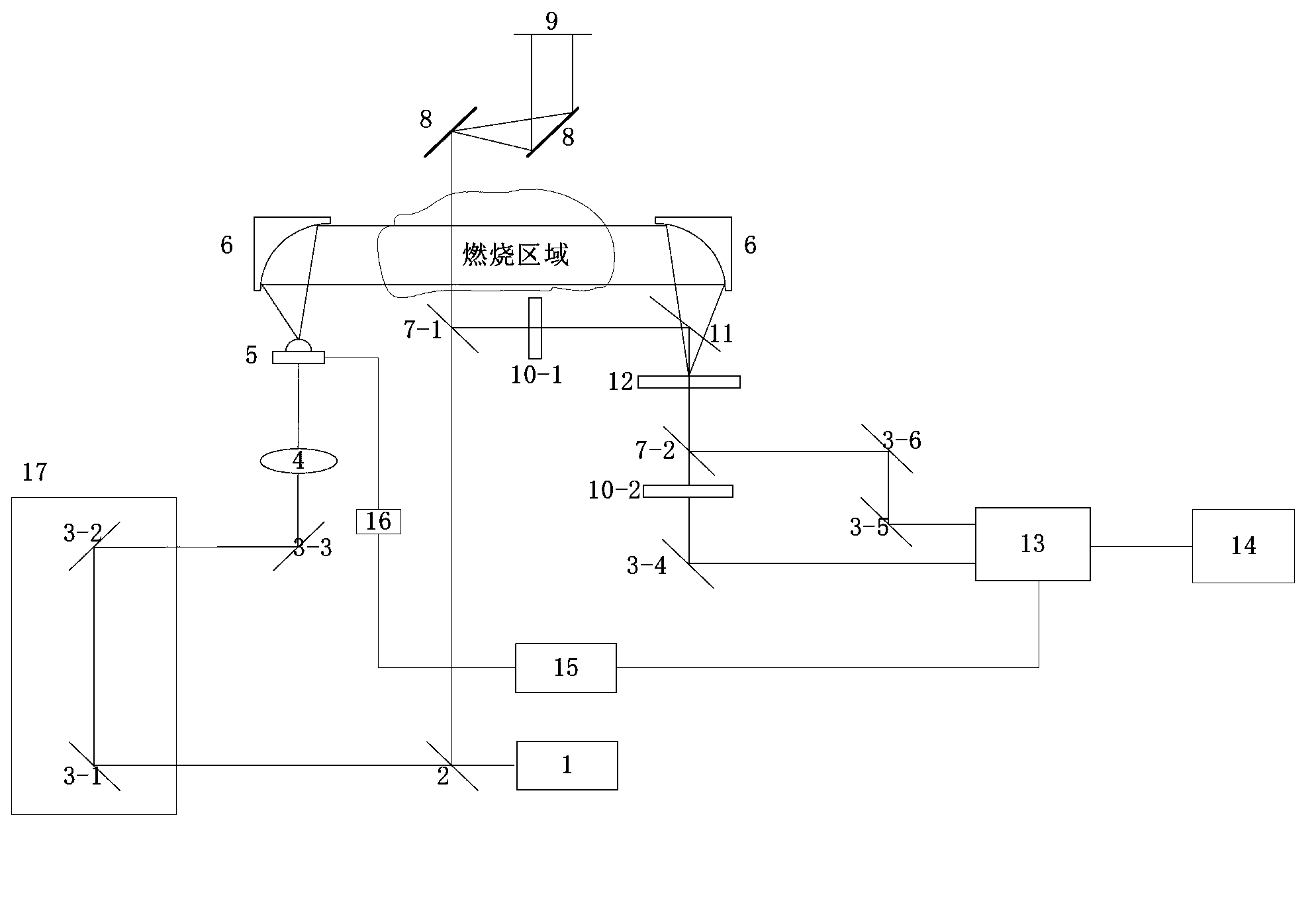

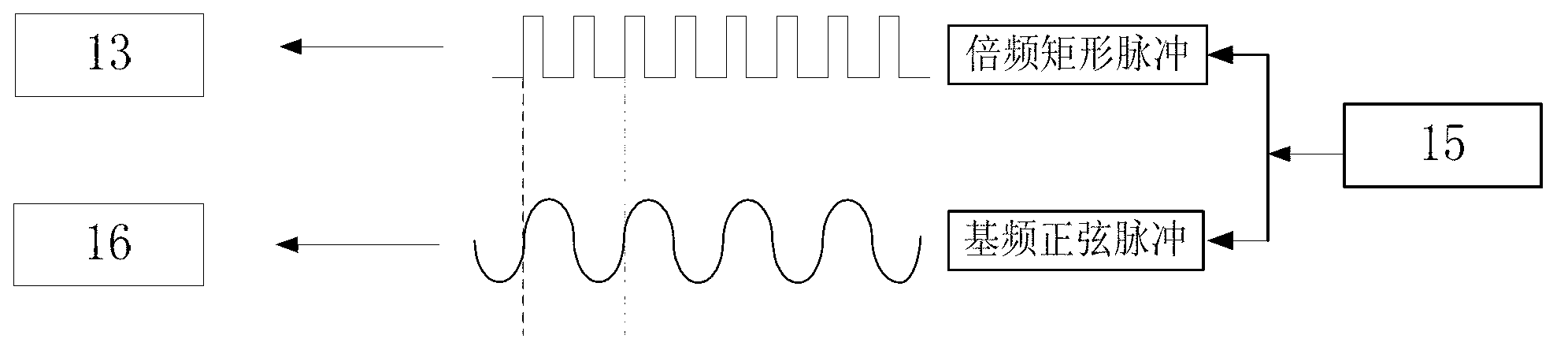

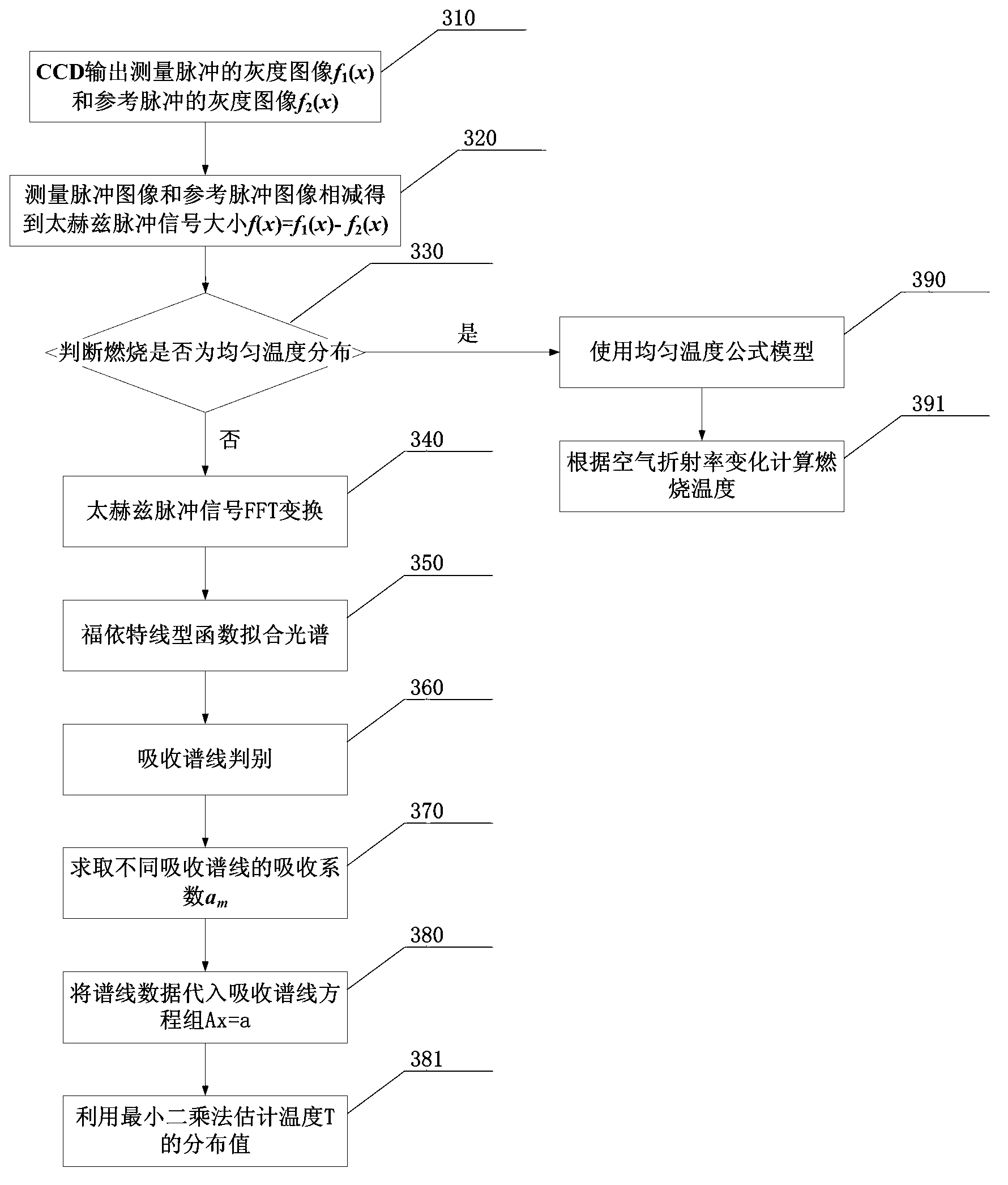

[0062] like figure 1 As shown, the combustion temperature sensing device based on terahertz pulse measurement includes a femtosecond laser 1, a beam splitter 2, a first plane mirror 3-1, a second plane mirror 3-2, and a third plane mirror 3 -3. Focusing lens 4, photoconductive antenna type terahertz transmitter 5, off-axis parabolic mirror group 6, first half mirror 7-1, second half mirror 7-2, parallel grating group 8, plane Mirror 9, first polarizer 10-1, second polarizer 10-2, ITO glass 11, ZnTe crystal 12, CCD detector 13, computer 14, function generator 15, high frequency power amplifier 16, one-dimensional optics Translation stage17.

[0063] The laser is emitted from the femtosecond laser 1, and after being split by the beam splitter 2, it is divided into two paths: the reference laser and the detection laser, in which the detection laser passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com