Copper-based catalyst prepared by ammonia distillation method and application of copper-based catalyst in oxidation carbonylation synthesis of alkyl carbonate

A copper-based catalyst and catalyst technology, applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, carbonate/haloformate preparation, etc., can solve problems such as equipment corrosion, catalyst deactivation, chlorine loss, etc., to achieve the elimination of activity Decrease, good stability, the effect of stable active components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Using copper acetate as the precursor, the process of preparing the catalyst by distilling ammonia is as follows: Weigh Cu(CH 3 COO) 2 ·H 2 O3.1g was added to a three-necked flask, then 70mL of distilled water was added, and after stirring until it was completely dissolved, 16mL of ammonia water (commercially available) with a mass fraction of 25% was slowly added dropwise to adjust the pH of the solution to 11~12, sealed and vigorously stirred for 30min, The stirring speed is 120 rpm. Then weigh 9g of commercially available NaY molecular sieve powder (Shanghai Xinnian Petrochemical Auxiliary Co., Ltd., n(SiO 2 ) / n(Al 2 o 3 )=10) Add 30mL of distilled water into a three-necked flask, stir vigorously at 20-25°C for 8h, and the stirring speed is 240 rpm. Use a super constant temperature water bath to raise the temperature to 80°C, and place the three-neck flask open, so that the ammonia in the system is evaporated until the slurry is neutral and stops stirring at 120...

Embodiment 2-4

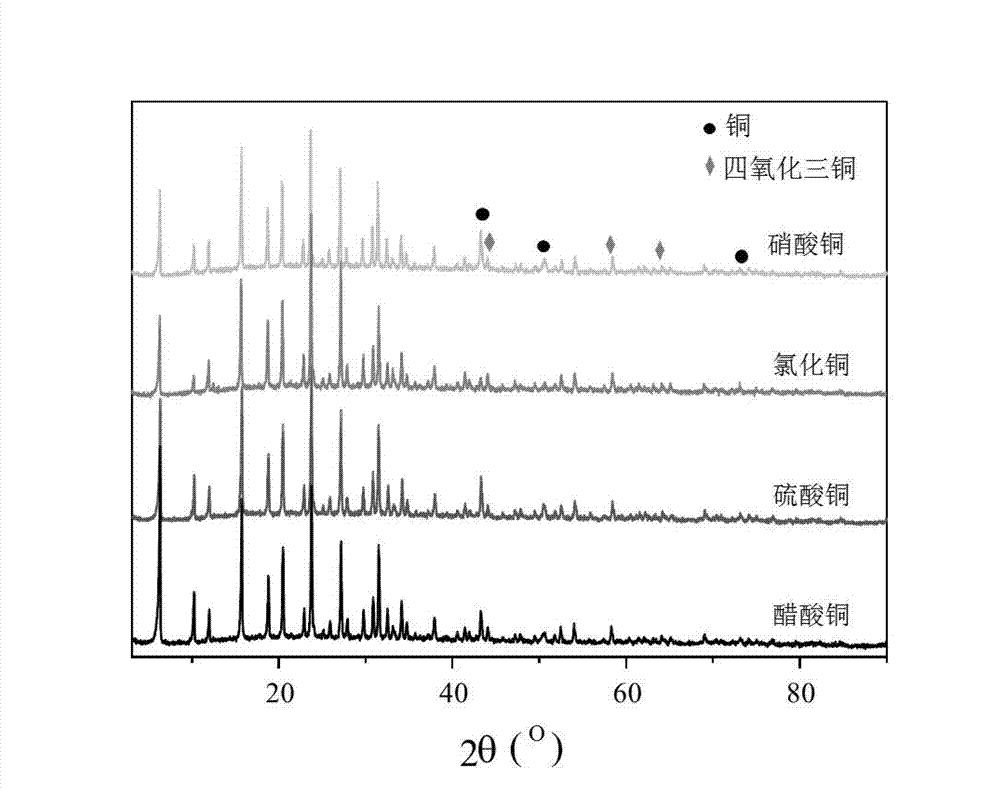

[0027] In the case that other experimental conditions are exactly the same as in Example 1, copper acetate was changed to copper nitrate, copper chloride and copper sulfate to ensure that the Cu loading accounted for 10% of the total catalyst mass. The obtained Cu-Y molecular sieve catalyst XRD spectrogram is as figure 2 As shown (XRD adopts the Rigaku D / max2500v / pc diffractometer of Japan Rigaku, and uses Cu / K-alphal rays as the light source for measurement. The target is a copper target, the 2θ angle measurement range is 3~90°, and the scanning speed is 8° / min, the test samples are all powder, the same below).

Embodiment 5-7

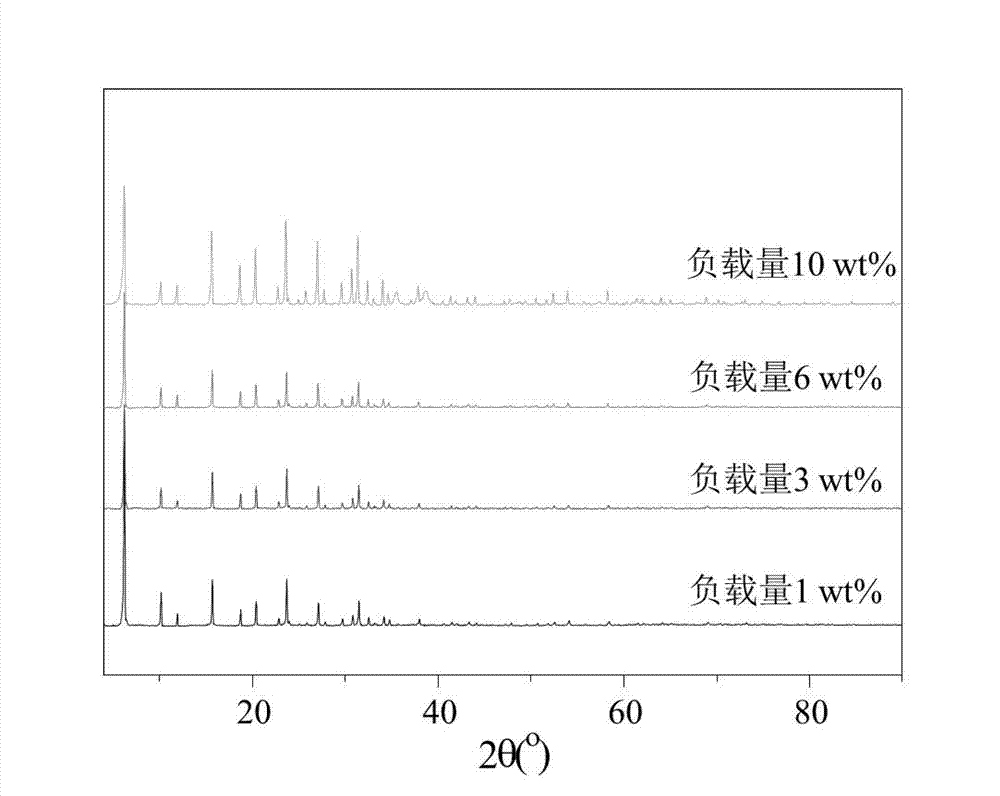

[0029] Under the completely identical situation of other experimental conditions and embodiment 2, the loading capacity of Cu is changed to 1wt.%, 3wt.%, 6wt.%, the Cu-Y molecular sieve catalyst XRD spectrogram that obtains is as follows figure 1 shown. Depend on figure 1 It can be seen that when the loading reaches or exceeds 10wt.%, metallic copper and Cu appear in the catalyst system 3 o 4 The appearance of a small amount of copper and its oxide crystals is beneficial to the catalyst activity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Space-time yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com