Synthetic method of carbon quantum dot material

A technology of carbon quantum dots and solvents, applied in the field of synthetic carbon quantum dot materials, can solve the problems of high energy consumption, cumbersome experimental process, expensive precursors and passivators, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

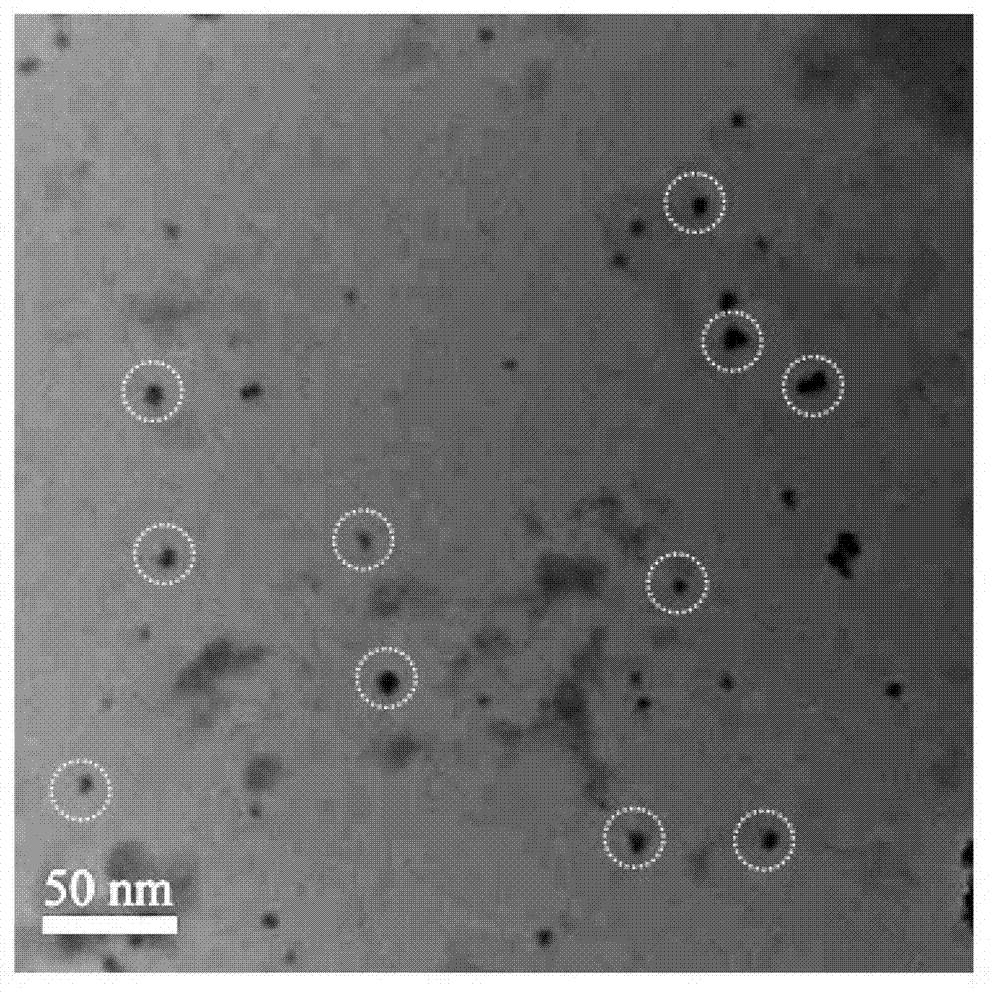

[0017] Dissolve 146 mg (1 mmol) of lysine and 1 mmol of L-ascorbic acid in 2.9 g of ethanol at room temperature, transfer the solution to an autoclave, and treat at 100 °C for 2 hours. After centrifuging to remove large suspended matter, the solvent is evaporated to obtain the carbon quantum dot material. figure 1 The transmission electron micrographs of carbon quantum dot materials synthesized under this condition are given.

[0018] As an optional replacement, lysine can also be replaced by glutamic acid, which can also realize the reaction to obtain carbon quantum dot materials.

Embodiment 2

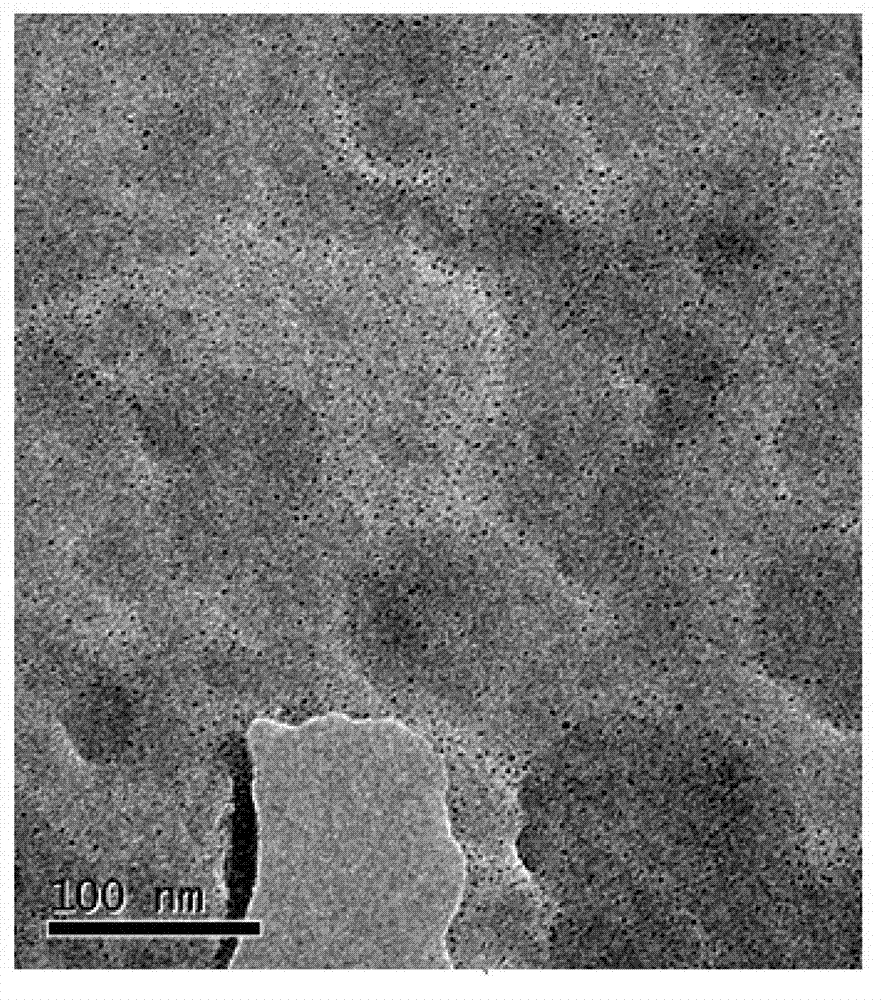

[0020] Dissolve 94 mg (1 mmol) of phenol and 10 mmol of L-ascorbic acid in 18.8 g of cyclohexane at room temperature, transfer the solution to an autoclave, and treat at 140°C for 10 hours. After centrifuging to remove large suspended matter, the solvent is evaporated to obtain the carbon quantum dot material. figure 2 The transmission electron micrographs of carbon quantum dot materials synthesized under this condition are given.

[0021] As an optional replacement, phenol can also be replaced by hydroquinone, catechol or p-cresol, and the reaction can also be realized to obtain carbon quantum dot materials.

Embodiment 3

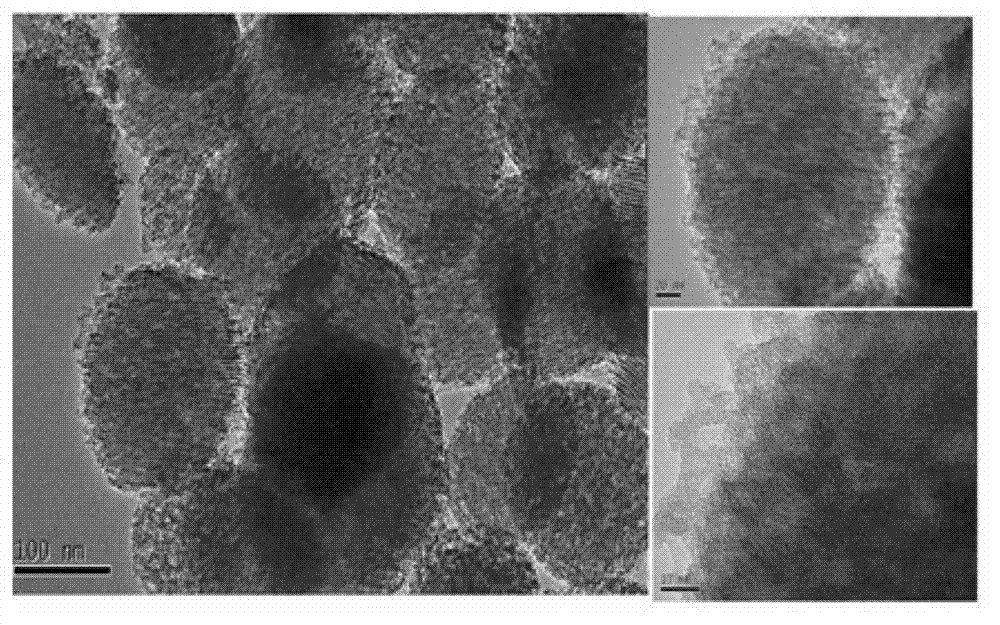

[0023] Disperse the mesoporous silica material (MCM-41) containing cetyltrimethylammonium bromide (1 mmol, 365 mg) and 30 mmol isoascorbic acid in 200 g of water at room temperature , the mixture was transferred to an autoclave and treated at 160°C for 30 hours. The mesoporous silicon oxide material is washed and filtered to obtain carbon quantum dots dispersed in the pores of silicon oxide. image 3 The transmission electron micrographs of carbon quantum dot materials synthesized under this condition are given.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com