Wet-method zinc oxide preparation method

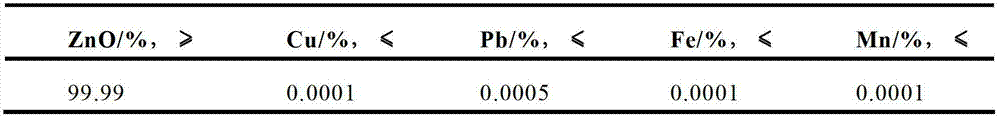

A zinc oxide, wet process technology, applied in the field of compound preparation, can solve the problems of difficult to clean, can only reach 95~99% in general, limited raw materials, etc., and achieves the effects of wide application, reduced production cost and wide application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

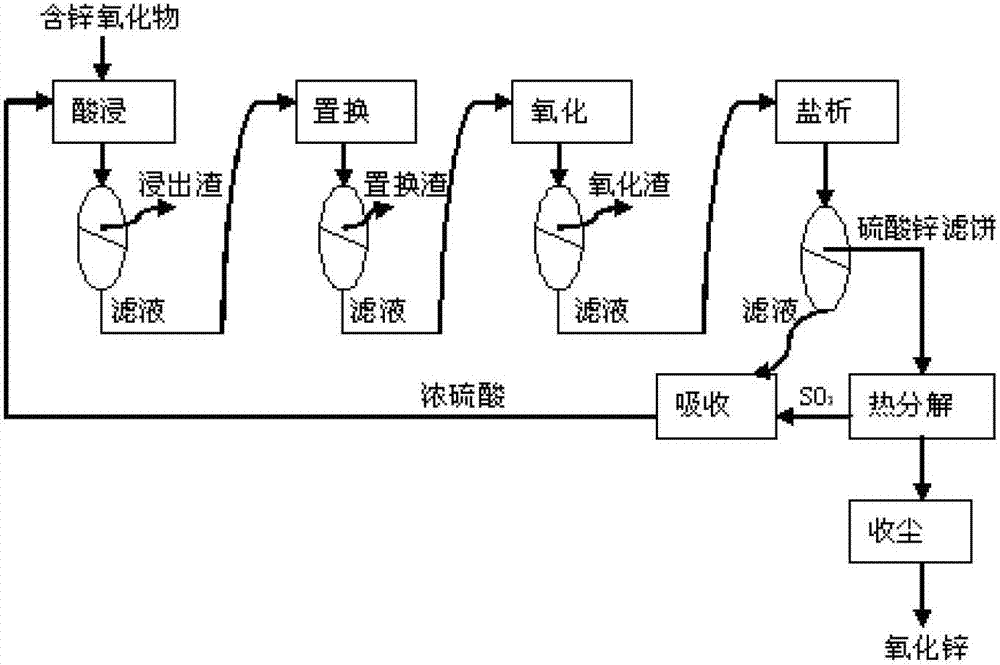

[0030] The invention provides a kind of preparation method of zinc oxide, and concrete scheme is as follows:

[0031] a) Acid leaching, displacement reaction, oxidation reaction, and salting out are carried out on the mixed oxide containing zinc to obtain salting out solution and zinc salt;

[0032] b) thermally decomposing the zinc salt to obtain zinc oxide;

[0033] c) Prepare the mother liquor by preparing other products except zinc oxide obtained after thermal decomposition in step b) and the salted-out solution obtained in step a), and repeat the operation of step a).

[0034] The method provided by the invention is based on the traditional acid method for preparing zinc oxide, catalyzing salting out of anhydrous or monohydrate zinc sulfate, and then thermally decomposing to obtain zinc oxide with higher purity. The specific method is as follows:

[0035] First, the mixed oxide containing zinc element is subjected to acid leaching, that is, directionally dissolved. The ...

Embodiment 1

[0054] Orientation leaching 200g of mixed oxides containing 80wt% zinc oxide in 800mL of 25% dilute sulfuric acid aqueous solution to obtain a metal sulfate mixture, and then vacuum filtering the obtained product to obtain leaching residue and leaching solution, leaching To remove the slag, add excess zinc powder to the leaching solution, replace other metal ions in the leaching solution with metal simple substances, and then perform vacuum filtration to obtain the replacement slag and replacement liquid, remove the replacement slag, and pass through the replacement liquid Excessive ozone, under the reaction of ozone and water, oxidizes low-valent metal ions to obtain MeOOH precipitates, and then performs vacuum filtration to remove the MeOOH precipitates to obtain an oxidized solution. Adjust the zinc ions in the oxidizing solution to saturation, and then add concentrated sulfuric acid with a concentration of 98wt% to the saturated zinc sulfate solution to precipitate zinc sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com