Method for producing cyanuric acid by utilizing industrial waste heat and tunnel type cracking furnace device

A technology of industrial waste heat and cyanuric acid, which is applied in the direction of furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of high energy consumption of urea cracking, low content of cyanuric acid, and low purity of finished products, and achieve good operating environment and high content , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

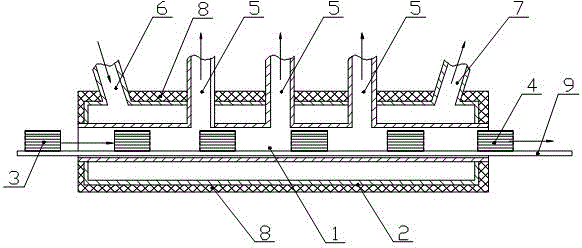

[0022] Sulfur dioxide gas at 900°C produced by sulfur incineration furnaces or fluidized fluidized furnaces in sulfuric acid enterprises enters through the input pipe 6 of industrial waste heat. into the conversion tower. At the same time, urea and cracking aids are input from the urea and cracking aids delivery device 3, and the crude cyanuric acid produced in the cracking reaction is output from the crude cyanuric acid output device 4, with a crude cyanuric acid content of 75-85%. The ammonia gas in the ammonia gas discharge pipeline 5 adopts the centralized collection mode of the induced draft fan, and then enters the dilute sulfuric acid kettle to generate ammonium sulfate product.

example 2

[0024] During the production of sulfuric acid enterprises, the medium-temperature gas of sulfur trioxide at 450°C from the outlet of the conversion tower enters through the input pipe 6 of industrial waste heat, and the temperature of the gas of sulfur trioxide drops to 200°C after passing through the tunnel cracking furnace device, and is discharged from the output pipe 7 of industrial waste heat. According to the process requirements, it will be cooled to below 100°C through the tube air cooling method and enter the dilute sulfuric acid absorption tower to absorb into 98% sulfuric acid or nicotinic acid. At the same time, urea and cracking aids are input from the urea and cracking aids delivery device 3, and the crude cyanuric acid produced by the cracking reaction is output from the crude cyanuric acid output device 4, with a crude cyanuric acid content of 65-80%. The ammonia gas in the ammonia gas discharge pipeline 5 adopts the centralized collection mode of the induced dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com