Edible chitosan green tea polyphenol active packaging film material and its preparation method

A technology of green tea polyphenols and chitosan, applied in the directions of packaging, wrapping paper, transportation and packaging, can solve the problems of difficulty in anti-oxidation, the anti-oxidation ability has not been developed, and browning, etc., and achieve water solubility. and water vapor transmission rate reduction, enhanced oxidation resistance, and the effect of maintaining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

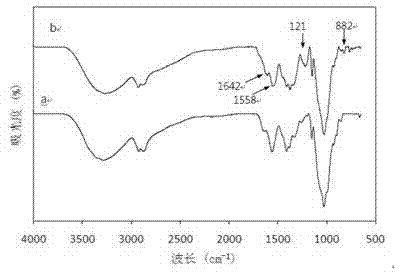

Method used

Image

Examples

preparation example Construction

[0035] 1) Preparation of dilute chitosan solution: Add chitosan with high degree of deacetylation to 0.5-1% dilute acetic acid, stir well until completely dissolved, filter with four layers of gauze to remove impurities, and prepare 1-2% chitosan dilute chitosan solution;

[0036] 2) Compounding with plasticizer: heat the plasticizer glycerin in a 50°C water bath to make it easy to absorb with a pipette, transfer it to the filtered chitosan dilute solution, and stir until it is evenly mixed.

[0037]3) Composite with emulsifier: use hydrophilic Tween 20 as emulsifier, use a pipette gun to draw emulsifier into the composite membrane solution, and stir until evenly mixed.

[0038] 4) Cross-linking with green tea polyphenols: add green tea extract green tea polyphenols into the mixed chitosan film solution, stir until fully dissolved, then homogenize with a homogenizer at 13500rpm for 2 minutes, mix the mixed The solution was evacuated until no air bubbles were visible.

[0039...

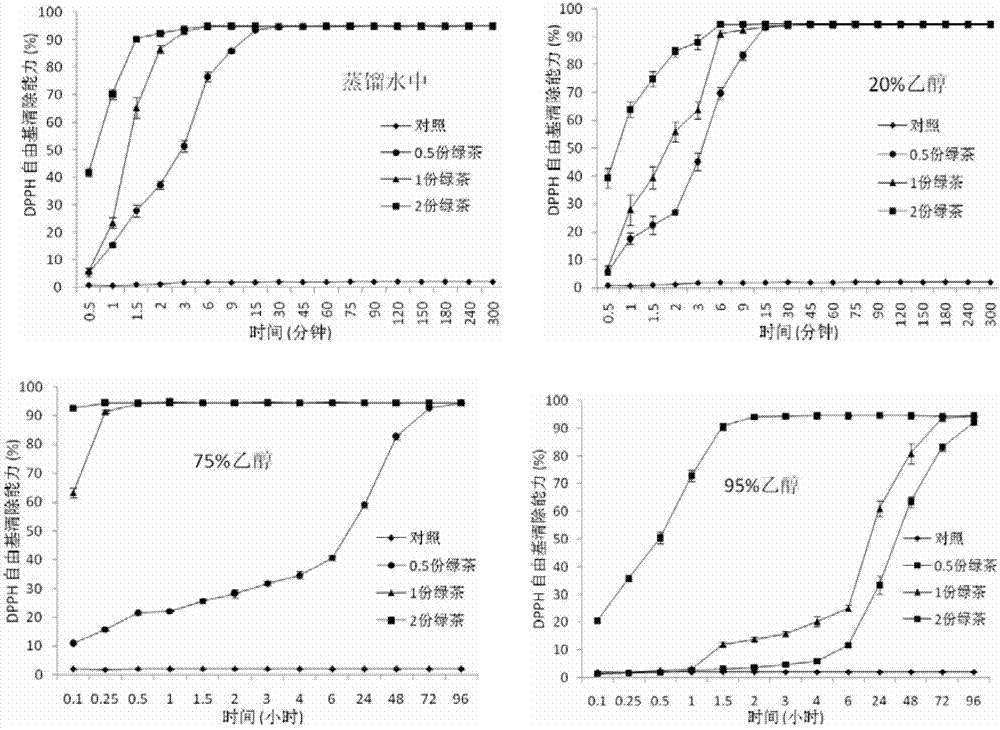

Embodiment 1

[0041] Dissolve 2 parts of crab chitosan (deacetylation degree 90.2%, viscosity 62cps) in 98 parts of 1% dilute acetic acid solution, stir thoroughly to obtain a chitosan solution with a weight ratio of 2%, and then place it on a magnetic stirrer Stir for 4 hours, filter, then add 0.5 parts of glycerin, stir again for 1 hour, green tea polyphenols are mixed into the chitosan solution at 0, 0.5, 1 and 2 parts respectively, stir well and then pass the German IKA high-speed homogenization The homogenizer was homogenized at 13500 rpm for 2 minutes, and vacuum degassed for 1 hour.

[0042] Each calculated degassed film-forming solution was poured on a flat glass plate with an area of 25cm×25cm to achieve a uniform thickness of about 70 microns, and dried at room temperature (about 25°C) for 2 days. The dried film was carefully peeled off from the glass plate, and cut into pieces of different sizes for index evaluation. The size of 60×60mm is used for the evaluation of water vapo...

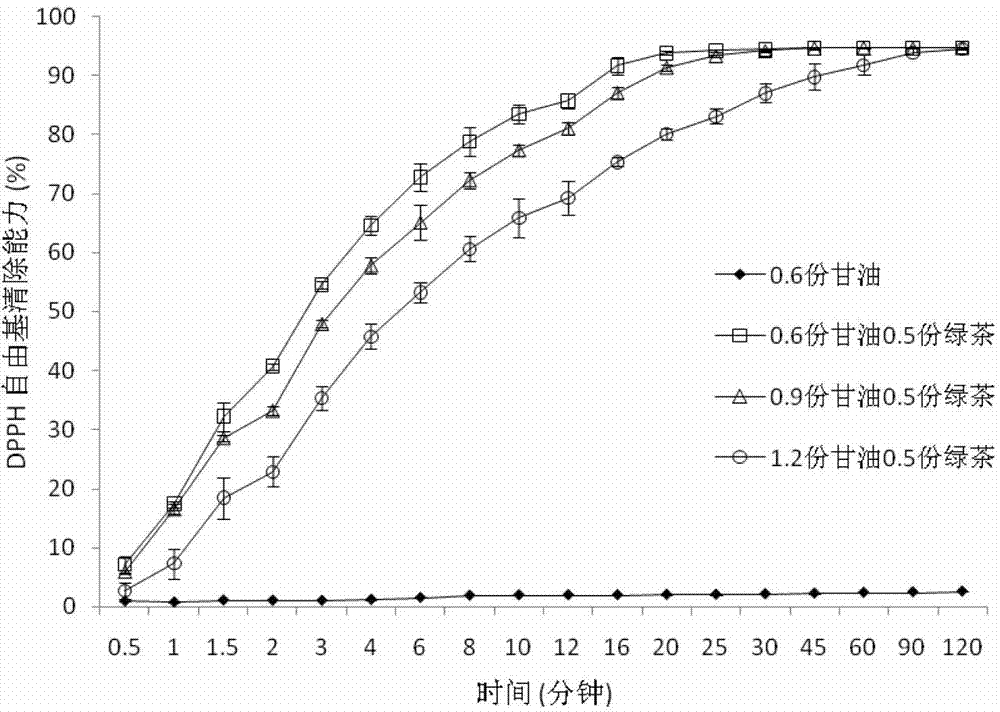

Embodiment 2

[0048] Dissolve 2 grams of crab chitosan in 98 parts of 1% dilute acetic acid solution, fully stir to obtain a 2% chitosan solution by weight, then stir for 4 hours on a magnetic stirrer, filter, and then add 0 , 0.6, 0.9 and 1.2 parts of plasticizer glycerin in different weights, magnetically stirred again for 1 hour, green tea polyphenols were mixed into the chitosan solution with 0 and 0.5 parts of weight, and after fully stirring, the homogenizer was used at 13500rpm Homogenize for 2 minutes and degas under vacuum for 1 hour.

[0049] Cast each degassed film-forming solution calculated on a flat glass plate with an area of 25cm×25cm to achieve a uniform thickness of about 70 microns, and dry at room temperature (around 25°C) for 2 days to form a film . Film samples were stabilized for a minimum of 2 days in a constant temperature and humidity chamber set at 25°C and 53% relative humidity prior to all measurements.

[0050] Utilize the active packaging film of chitosan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com