Hyperdispersant for carbon nanotubes and manufacturing method thereof

A technology of hyperdispersant and carbon nanotubes, which is applied in the treatment of dyed polymer organic compounds, fibrous fillers, etc., can solve the problems of reduced compression resistance and wear resistance, large pollution, high cost, etc., and achieve stable dispersion performance. , High product yield, good environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

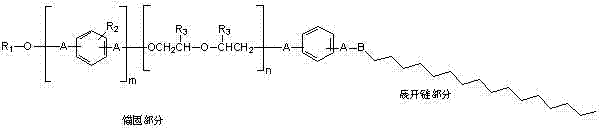

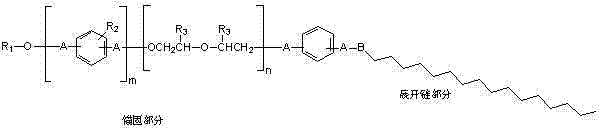

[0034] Embodiment 1, a kind of hyperdispersant for carbon nanotube, its general formula is as follows:

[0035]

[0036] In the formula:

[0037] R 1 is hydrogen, alkyl, alkoxyalkyl, hydroxyalkoxyalkyl;

[0038] A is methyl, carbonyl; A connected to the same benzene ring is the ortho, para or meta position of the benzene ring;

[0039] R 2 is alkyl, alkoxy, phenoxy;

[0040] R 3 is hydrogen, methyl;

[0041] B: for O-CH 2 CH 2 -O, (O-CH 2 CH) a -O, NHCH 2 CH 2 NH, (NHCH 2 CH 2 ) b -NH, B is the bridge connection part between the anchor part and the unfolding chain part;

[0042] The extended chain part is ethylene oxide homopolymer, propylene oxide polymer, ethylene oxide / propylene oxide copolymer, linear polyester, nonlinear polyester;

[0043] The molecular weight ratio of the anchor part and the extended chain part is 1:1-1:100;

[0044] Both m and n are positive integers of 1-50. ,

Embodiment 2

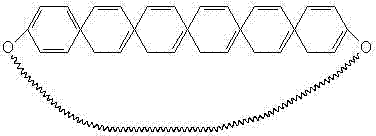

[0045] Example 2, in the hyperdispersant for carbon nanotubes described in Example 1: the anchoring part in the general formula is a polyether containing a benzene ring, or a polyester containing a benzene ring.

Embodiment 3

[0046] Embodiment 3, a kind of preparation method for the hyperdispersant of carbon nanotube as described in embodiment 1 or 2, its steps are as follows:

[0047] (1) Put dichlorobenzyl, polyethylene glycol 400, or polypropylene glycol 600, or polyether into the reaction vessel, raise the temperature to 150°C and keep it warm for 2 hours, add triethanolamine, and continue the reaction for 2 hours; cool down to 50°C, add an appropriate amount Diluted with water, static layered, separated the lower layer solution, removed the water layer, repeated 2 times, placed in a constant temperature oven at 95°C, and baked for 5 hours to obtain an anchoring group intermediate; the dichlorobenzyl, triethanolamine and The weight ratio of polyethylene glycol 400 or polypropylene glycol 600 or polyether is 150:70:350;

[0048] (2) Put the anchoring group intermediate, polyether-modified phthalic acid and p-toluenesulfonic acid into the reaction vessel, raise the temperature to 180°C, and keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| suspension rate | aaaaa | aaaaa |

| suspension rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com