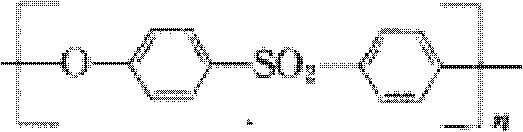

Preparation method of Polyethersulfone fibers

A technology of polyethersulfone fiber and polyethersulfone resin, which is applied in the field of preparation of polyethersulfone fiber, can solve problems such as increased cost and complicated equipment, and achieve the effects of saving time, simplifying the preparation process, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The polyethersulfone chips are vacuum-dried to a water content of <200ppm, and melted and extruded by a single-screw extruder. The temperature of each zone of the screw is: 305°C in the feed section, 317°C in the compression section, 322°C in the melting section, and 332°C in the metering section. After passing through the spinning assembly (spinning temperature is 345°C), it is cooled and solidified through the spinning tunnel under the condition of side blowing, and the oiled silk is directly introduced into the drafting and shaping winding machine, and is drawn on the upper and lower hot rollers. Shaping, wherein the temperature of the upper hot roller is 96°C, the speed is 445m / min, the temperature of the lower hot roller is 135°C, the speed is 848m / min, the draft ratio is 1.9 times, and the coiling speed of the winder is 830m / min.

[0030] The finally obtained polyethersulfone fiber has a monofilament fineness of 7.2 dtex, a breaking strength of 2.2 CN / dtex, and a ...

Embodiment 2

[0032]The polyethersulfone chips are vacuum-dried to a water content of <200ppm, and melted and extruded by a single-screw extruder. The temperature of each zone of the screw is: 320°C in the feed section, 330°C in the compression section, 332°C in the melting section, and 343°C in the metering section. After passing through the spinning assembly (spinning temperature is 345°C), it is cooled and solidified through the spinning tunnel under the condition of side blowing, and the oiled silk is directly introduced into the drafting and shaping winding machine, and is drawn on the upper and lower hot rollers. Shaping, wherein the temperature of the upper hot roller is 110°C, the speed is 556m / min, the temperature of the lower hot roller is 128°C, the speed is 1334m / min, the draft ratio is 2.4 times, and the coiling speed of the winder is 1300m / min.

[0033] The finally obtained polyethersulfone fiber has a monofilament fineness of 6.5 dtex, a breaking strength of 3.0 CN / dtex, and ...

Embodiment 3

[0035] The polyethersulfone chips are vacuum-dried to a water content of <200ppm, and melted and extruded by a single-screw extruder. The temperature of each zone of the screw is: 335°C in the feed section, 360°C in the compression section, 370°C in the melting section, and 380°C in the metering section. After passing through the spinning assembly (spinning temperature is 345°C), it is cooled and solidified through the spinning tunnel under the condition of side blowing, and the oiled silk is directly introduced into the drafting and shaping winding machine, and is drawn on the upper and lower hot rollers. Shaping, wherein the temperature of the upper hot roller is 125°C, the speed is 1055m / min, the temperature of the lower hot roller is 147°C, the speed is 1947m / min, the draw ratio is 1.8 times, and the coiling speed of the winder is 1900m / min.

[0036] The finally obtained polyethersulfone fiber has a monofilament fineness of 12.0 dtex, a breaking strength of 1.6 CN / dtex, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com