Flame-retardant insulation vulcanized fiber board and manufacturing technique thereof

A steel board and flame retardant technology, which is applied in the field of manufacturing flame retardant insulating steel board, can solve the problems of inability to meet the needs of the electrical industry and cannot produce flame retardant insulating steel board, and achieves easy control, low production cost, The effect of less water and electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

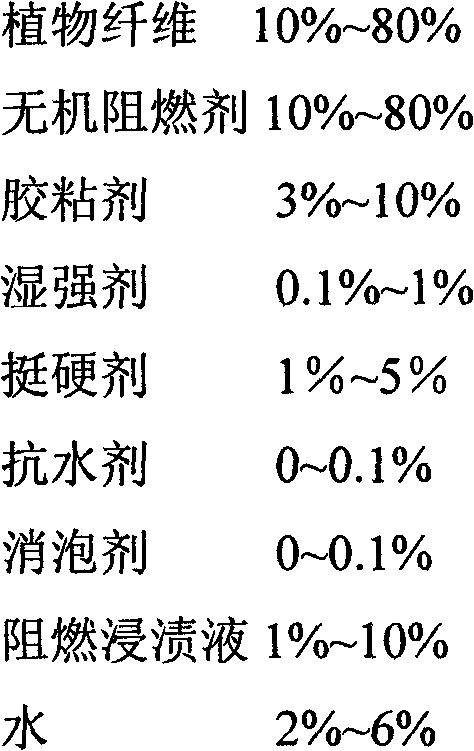

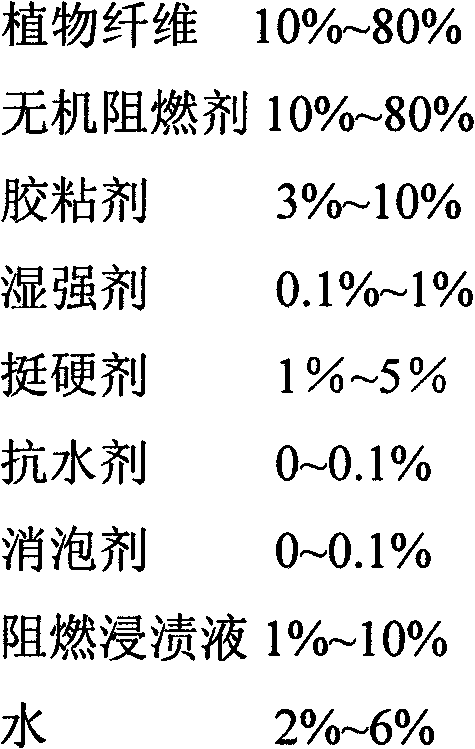

Method used

Image

Examples

example 1

[0032] 1. The bleached wood pulp fiber is subjected to fiberization and beating treatment with beating equipment, and the beating degree of the wood pulp fiber is beaten to 45°SR. Then add zinc borate inorganic flame retardant and fully mix with wood pulp fiber in beating equipment, the mixing ratio of wood pulp fiber and zinc borate inorganic flame retardant is 6: 4, and concentration is 5%;

[0033] 2. Prepare polyvinyl alcohol and melamine formaldehyde resin into solutions with a concentration of 5%, and then uniformly mix them according to a ratio of 1:1, and then dilute to a concentration of 1% for later use;

[0034] 3. Extract 1000kg of the above-mentioned mixed slurry from the slurry forming tank into the slurry mixing tank, and add 1.5kg of wet strength agent (concentration 12.5%), adhesive (concentration 50%) 5kg, stiffening agent (concentration 1%) in order ) 200kg, anti-water agent (concentration 1%) 25kg, defoamer (concentration 0.5%) 5kg and other components, mix...

example 2

[0040] 1. Use beating equipment to perform fibrosis and beating treatment on bleached wood pulp fibers, and beat the beating degree of wood pulp fibers to 35°SR; use beating equipment to perform fibrillation and beating treatment on white office waste paper, and beat the beating degree of waste paper pulp to 55° SR;

[0041] 2. Add above-mentioned beaten wood pulp fiber (concentration 5%) in the pulping tank, white office waste paper (concentration 5%), zinc borate inorganic flame retardant (powder) fully mix, wood pulp fiber (concentration 5%) %), white office waste paper (concentration 5%), the mixing ratio of zinc borate inorganic flame retardant (powder) is 5: 1: 4;

[0042] 3. Prepare polyvinyl alcohol and melamine formaldehyde resin into solutions with a concentration of 5%, and then mix them uniformly according to a ratio of 1:1, and then dilute to a concentration of 1% for later use;

[0043] 4. Extract 1000kg of the above-mentioned mixed slurry from the slurry formin...

example 3

[0049]1. Carry out fibrosis and beating treatment with beating equipment for bleached wood pulp fiber, and the beating degree of wood pulp fiber is beaten to 45 ° SR; °SR;

[0050] 2. Add above-mentioned beaten wood pulp fiber (concentration 5%) in the pulping tank, hemp pulp fiber (concentration 5%), zinc borate inorganic flame retardant (powder) fully mixes, wood pulp fiber (concentration 5%) ), hemp pulp fiber (concentration 5%), the mixing ratio of zinc borate inorganic flame retardant (powder) is 5: 2: 3;

[0051] 3. Prepare polyvinyl alcohol and melamine formaldehyde resin into solutions with a concentration of 5%, and then mix them uniformly according to a ratio of 1:1, and then dilute to a concentration of 1% for later use;

[0052] 4. Extract 1000kg of the above-mentioned mixed slurry from the slurry forming tank into the slurry mixing tank, and add 1.5kg of wet strength agent (concentration 12.5%), adhesive (concentration 50%) 5kg, stiffening agent (concentration 1%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com