Organic-silicon pouring sealant composition with high thermal conductivity and application thereof

A technology of organic silica gel and composition, which is applied in the treatment of dyed organic silicon compounds, other chemical processes, fibrous fillers, etc., can solve the problem of limited surface coating effect of inorganic powders, increase the viscosity of thermally conductive silicone mixtures, and silicone mixtures Viscosity increase and other problems, achieve good organic coating effect, prevent the increase of adhesive viscosity, and reduce the effect of van der Waals force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

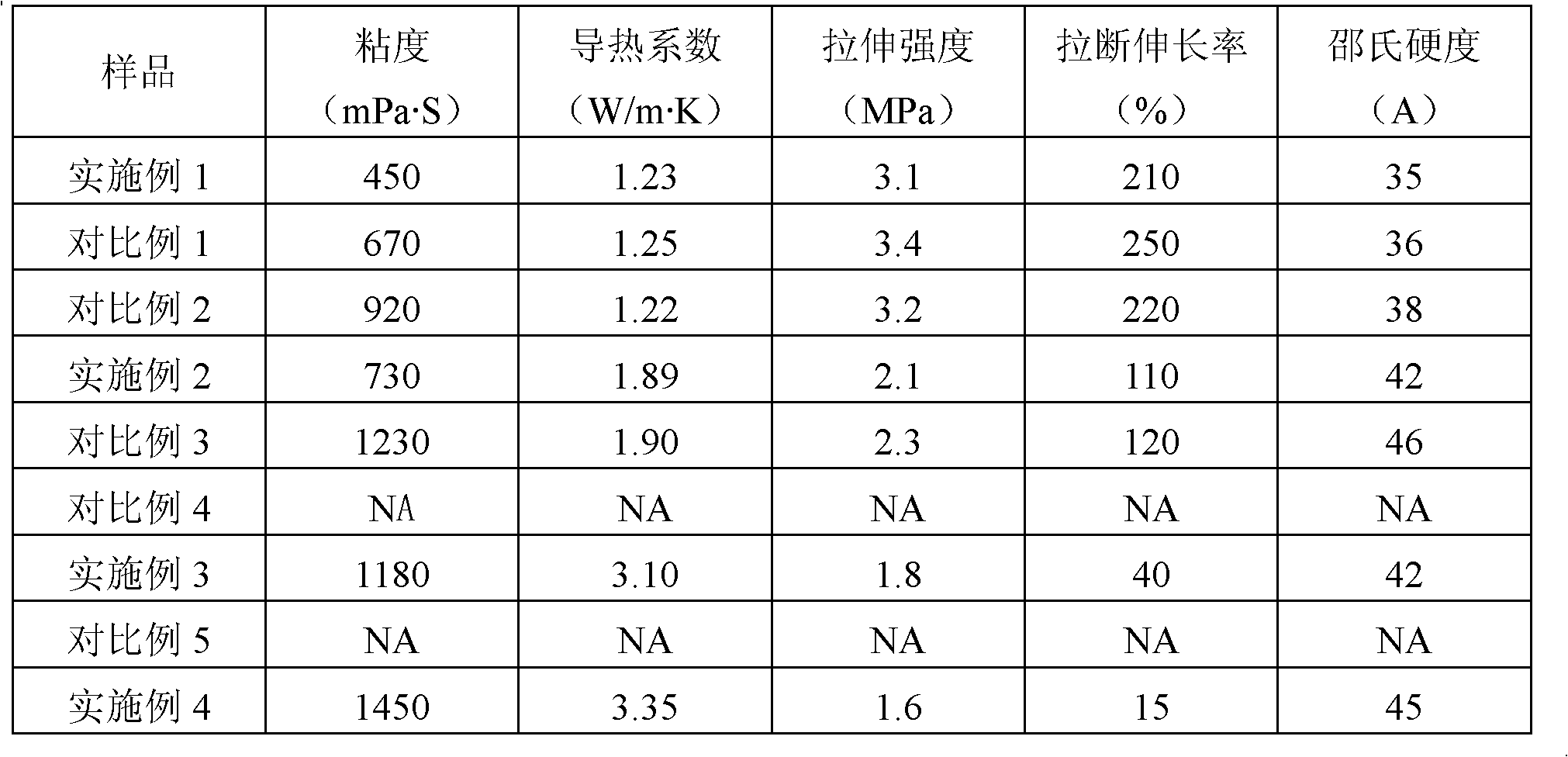

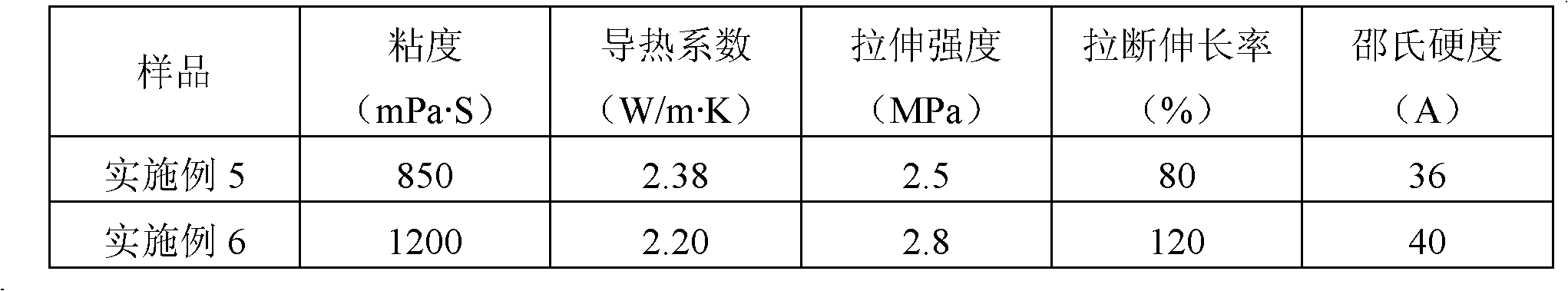

Embodiment 1

[0050] This example is used to illustrate the silicone potting compound composition provided by the present invention and its preparation method.

[0051] Add 1000g of α-alumina powder (average particle size of 30μm) and 400g of isobutanol into a 2L reaction kettle, heat the formed suspension to 90°C while stirring, and add 4g of vinyl tris (β-methoxyethoxy) silane, after 90min of heat preservation, stop heating, after the temperature drops to room temperature, add 50g of polymethylvinylsiloxane (ethylene content is 1.2% by weight, viscosity at 25°C is 100mm 2 / s) and 3g of hydrogen-containing silicone oil (hydrogen content 1.5% by weight, viscosity at 25°C is 30mm 2 / s), then drip the ethanol solution 100g (concentration is 1.5% by weight) of the platinum complex compound coordinated by methylpolysiloxane, the rate of addition is 5g / min, after the dropwise addition, continue to stir for 4h, and suction filter , put the obtained powder into a blast oven at 100° C. for 2 hours...

Embodiment 2

[0070] This example is used to illustrate the silicone potting compound composition provided by the present invention and its preparation method.

[0071] Except that 600 g of the silicone-coated alumina prepared in Example 1 was weighed for components A and B, instead of 400 g, the rest was the same as that of Example 1.

Embodiment 3

[0080] This example is used to illustrate the silicone potting compound composition provided by the present invention and its preparation method.

[0081] Except that components A and B weigh 900 g of the silicone-coated alumina prepared in Example 1 instead of 400 g, the rest is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com