Method for high efficiency enrichment culture of microalgae

A technology of enrichment culture and microalgae, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem of insufficient use of microalgae cells to fix carbon dioxide and the corresponding improvement in the accumulation efficiency of oil and fat. Cost and other issues, to achieve the effect of fast reproduction, improved quality, and reduced equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

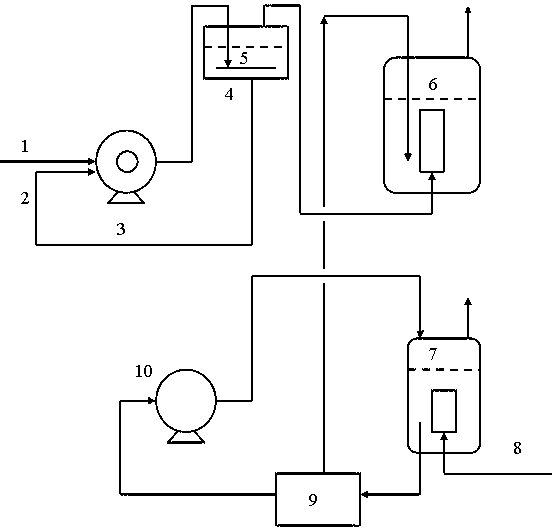

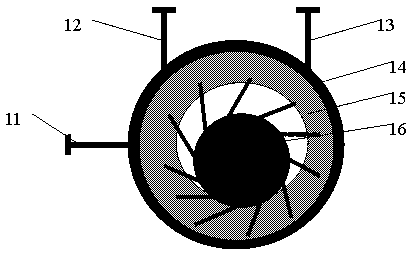

[0027] In the method of the present invention, the culture reactor used for microalgae enrichment is an air-lift reactor, and air is introduced to carry out aerobic heterotrophic culture, and the culture medium in the reactor is a conventional heterotrophic algae culture medium. In addition to the basic nutrients necessary for the growth of microalgae, the heterotrophic medium mainly includes organic carbon sources, such as glucose, sucrose, starch, xylose, cellulose hydrolyzate, etc.

[0028] In the method of the present invention, the algae cells cultured heterotrophically in the air-lift bioreactor are enriched through the enrichment device, and the enrichment device adopted is a metal filter screen, and a back blowing device is provided, so that the enrichment device can be enriched The obtained microalgae cell slurry is blown into the light-type bioreactor for the next step of the photoautotrophic culture process.

[0029] In the method of the present invention, in the il...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com