Method for continuous cycle fermentation production of citric acid

A technology of cyclic fermentation and citric acid, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of low degree of fermentation automation, large fluctuations in the quality of fermentation liquid, and large investment in fermentation equipment, so as to improve the fermentation process. Conversion rate, realization of mechanization and automation, effect of reducing equipment cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

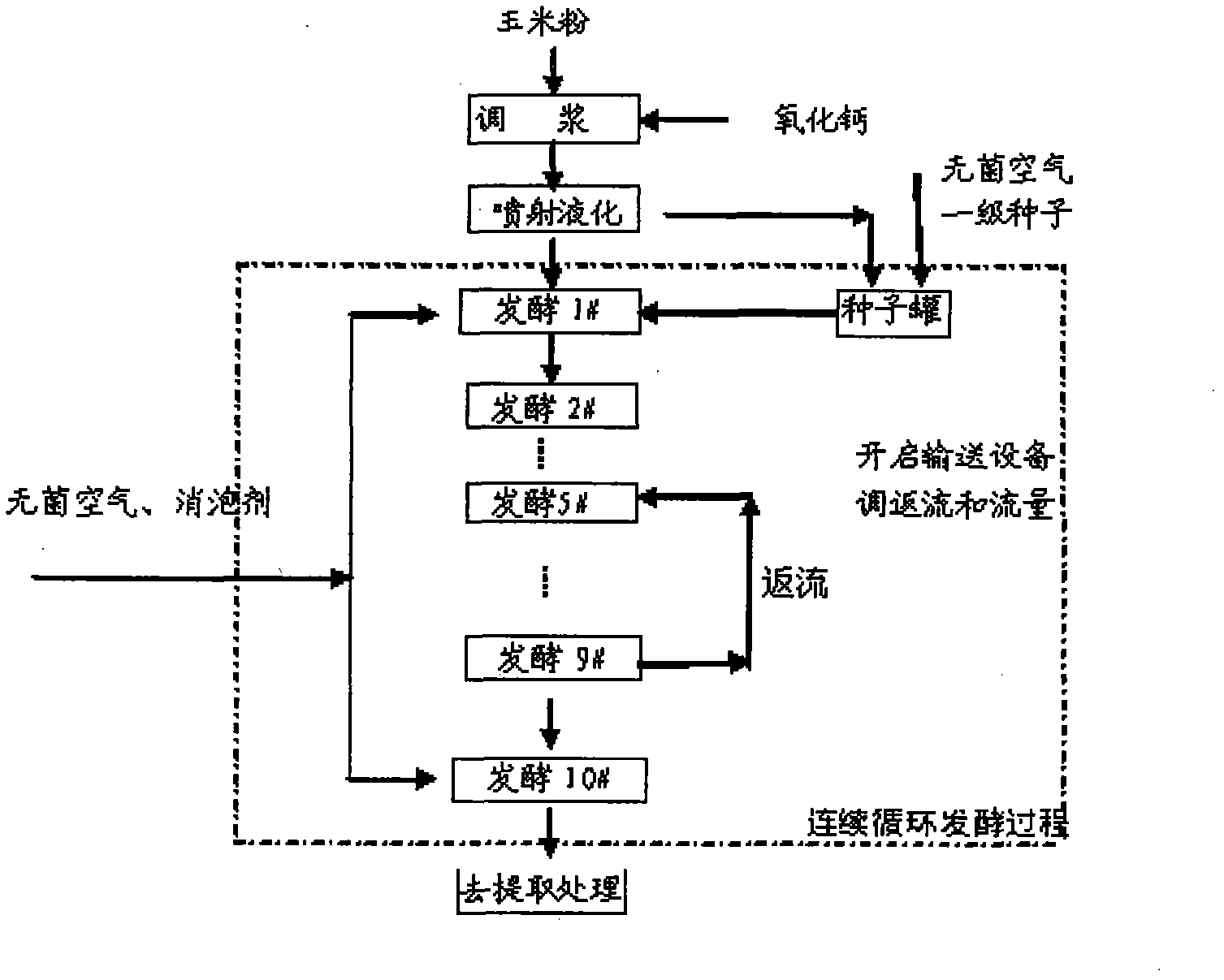

[0018] The invention is equipped with high-efficiency combined pipeline conveying equipment, which is composed of cascaded fermentation tanks, and adopts 8 to 10 fermentation tanks in each line for single-line continuous production. The steps are as follows:

[0019] a. Blending: Mix 4t of starch milk and 2t of corn flour into the blending tank, add 24L of high-temperature amylase, start stirring, add hot water at a temperature of 45°C to set the volume to 40m 3 , use calcium oxide to adjust the pH value to 6.0;

[0020] b. Jet liquefaction: preheat the injector and laminar flow tank first, then turn on the injector, pump the adjusted slurry into the jet heater and mix it with steam. The temperature is controlled at 90°C, and the steam pressure is kept at 0.35MPa. Then enter the laminar flow tank for heat preservation, and the heat preservation time is 35 minutes to complete the liquefaction;

[0021] c. Continuous elimination and sterilization: first use a continuous pump t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com