New process for preparing meleumycin

A kind of melemycin, a new process technology, applied in the field of microbial production of melemycin, can solve the problems of backwardness, high cost of extraction process, complicated organic solvent recovery process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

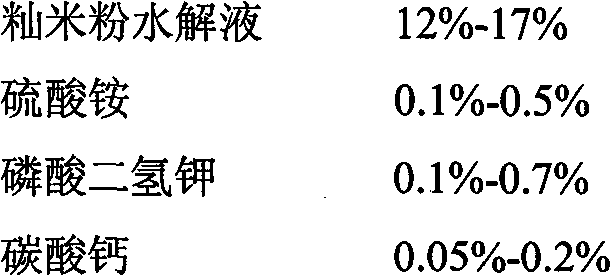

Examples

Embodiment 1

[0010] seed culture

[0011] Medium: 13% indica rice flour hydrolyzate, 1% sucrose, 0.2% peptone, 0.1% ammonium sulfate, 0.1% potassium dihydrogen phosphate, and the rest is distilled water.

[0012] ①Incline seed culture

[0013] The preserved strains were inoculated on the slant medium with an inoculation needle, and cultured at 28°C for 7 days.

[0014] ② Primary seed culture medium

[0015] Add 50mL of seed medium into a 250mL shake flask, sterilize and cool down, then connect a ring of well-grown slant culture, and cultivate at 28°C and 200r / min for 48h.

[0016] ③ Secondary seed culture solution

[0017] Add 3L of seed culture medium into a 5L shake flask, sterilize and cool, add 60mL of primary seed culture medium, and cultivate at 28°C and 200r / min for 48h.

[0018] ④Tertiary seed culture solution

[0019] Add 9L of seed culture medium into a 15L shake flask, sterilize and cool, add 2.7L of secondary seed culture medium, and cultivate at 28°C and 200r / min for 48h....

Embodiment 2

[0032] Seed culture is the same as example 1

[0033] Fermentation culture

[0034] Fermentation medium: 15% of indica rice flour hydrolyzate, 0.3% of ammonium sulfate, 0.1% of potassium dihydrogen phosphate, 0.08% of calcium carbonate, and the rest is distilled water.

[0035] Add 50L of fermentation medium and an appropriate amount of defoamer to a 100L automatic fermentation tank, sterilize at 0.1MPa for 30 minutes, cool to 28°C, insert 16.0L of tertiary seed culture medium, and the ventilation rate is 1.1-1.2V / V / min, the stirring speed is 500-700r / min, the fermentation temperature is 28°C, and after 72 hours of fermentation, centrifuge to obtain the melemycin fermentation broth.

[0036] Extraction of melelamycin

[0037] ①Extraction

[0038] Add a quantitative amount of mebamycin fermentation broth to the extraction tank, adjust the pH value to 8.0-9.0 with a saturated solution of sodium bicarbonate, and then add 1.5 times the volume of the extraction solution of isop...

Embodiment 3

[0045] Seed culture is the same as example 1

[0046] Fermentation culture

[0047] Fermentation medium: 17% of indica rice flour hydrolyzate, 0.5% of ammonium sulfate, 0.7% of potassium dihydrogen phosphate, 0.2% of calcium carbonate, and the rest is distilled water.

[0048] Add 50L fermentation medium and an appropriate amount of defoamer to a 100L fully automatic fermentation tank, sterilize at 0.1MPa for 30min, cool to 28°C, insert 16.0L of tertiary seed culture medium, and the ventilation rate is 1.0-1.2V / V / min, the stirring speed is 500-700r / min, the fermentation temperature is 28°C, and centrifuged to obtain the mebamycin fermentation broth.

[0049] Extraction of melelamycin

[0050] ①Extraction

[0051] Add a quantitative amount of mebamycin fermentation broth to the extraction tank, adjust the pH value to 8.0-9.0 with a saturated solution of sodium bicarbonate, and then add 3 times the volume of the extraction solution of octanol and aviation kerosene (V / V=5:2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com