Function coating imaging-self method of polydimethylsiloxane three-dimensional structure

A technology of polydimethylsiloxane and dimethylsiloxane, which is applied in the field of self-patterning of functional coatings of polydimethylsiloxane three-dimensional structure, achieves high coverage, easy observation and control, and good effect. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

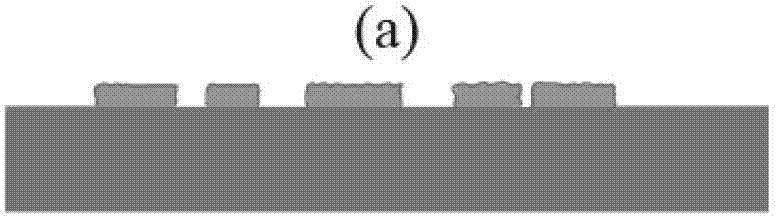

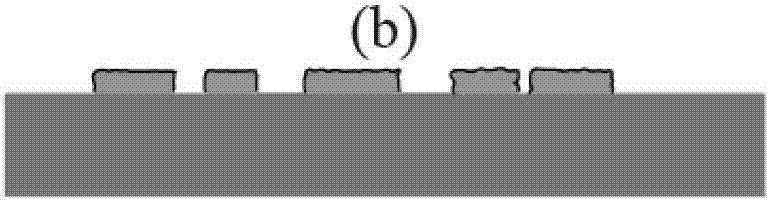

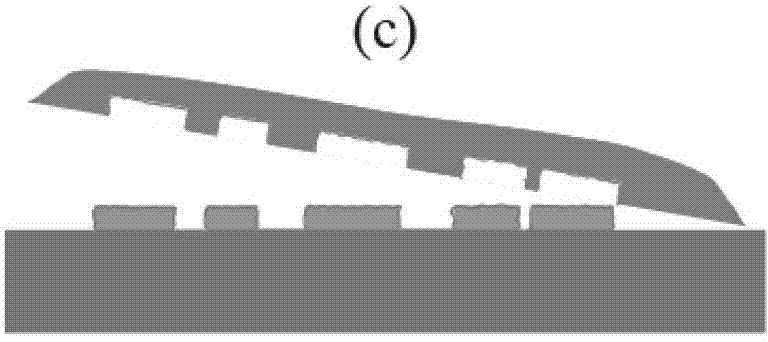

[0034] Such as Figure 1-7 Shown in, (a) roughening of SU-8 pattern; b) Deposition C x f y polymer; (c) polydimethylsiloxane casting and release; (d) covering polydimethylsiloxane with a volatile solution; (e) evaporating until the solution only remains on the rough surface; (f ) coating curing; (g) polydimethylsiloxane-glass bonding. The process flow is as follows:

[0035] 1) Fabrication of three-dimensional microstructure: uniformly coat the SU-8 negative resist layer on the silicon wafer; after alignment and photolithography, perform photolithography treatment on the SU-8 negative resist layer to form a number of penetrating second photoresist layers through holes, and three-dimensional microstructures are arranged between adjacent through holes;

[0036] 2) Wetting property modification: use oxygen plasma etching surface treatment technology to make the surface of the three-dimensional microstructure rough, while the substrate remains smooth;

[0037] 3) Deposition: ...

Embodiment 2

[0055] This embodiment is the same as Embodiment 1 except for the following features: the functional coating material is glass resin, the commercial model is GR650 F; the solvent is toluene, and the concentration of toluene is 1-35 wt%. Among them, GR650F with a concentration of 3.5 wt%, was uniformly covered by the toluene solution in the polydimethylsiloxane (PDMS) microwell after curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com