Cefixime capsule and preparation method thereof

A technology of cefixime and capsules, which is applied in the field of cefixime capsules and its preparation, can solve the problems affecting the speed and effect of drug treatment, slow drug absorption and distribution, and low dissolution rate, so as to shorten the production cycle and reduce production costs , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

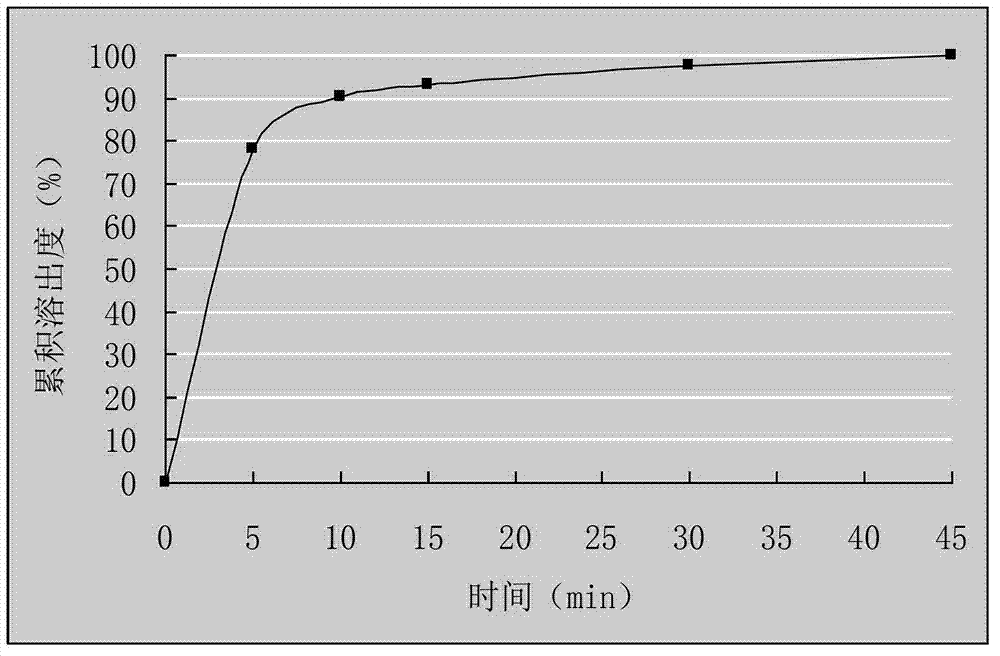

Embodiment 1

[0021] Dissolve 500g of cefixime and 750g of lecithin in 10L of methanol, add 200g of silicon dioxide, and stir; evaporate the methanol to dryness under reduced pressure below 50°C, take out the evaporated compound, grind it through a 80-100 mesh sieve, and obtain The cefixime phospholipid complex of silicon dioxide; take by weighing 145g the cefixime phospholipid complex containing silicon dioxide, dry granulate after mixing with 180g lactose, 30g croscarmellose sodium, the gained dry granule and 3.5 g of talcum powder was mixed evenly and filled into capsule shells to obtain cefixime capsules.

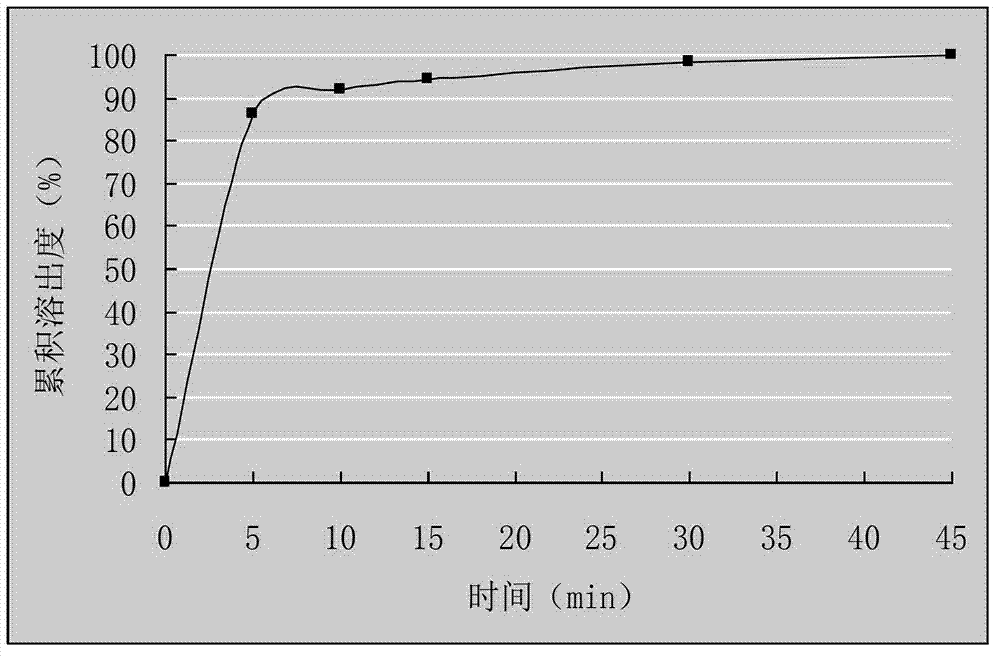

Embodiment 2

[0023] Dissolve 500g of cefixime and 1000g of lecithin in 10L of methanol, add 250g of silicon dioxide, and stir; evaporate the methanol to dryness under reduced pressure below 45°C, take out the evaporated compound, crush it through a 80-100 mesh sieve, and obtain The cefixime phospholipid complex of silicon dioxide; take by weighing 175g the cefixime phospholipid complex containing silicon dioxide, dry granulate after mixing with 200g microcrystalline cellulose, 25g crospovidone, the gained dry granule and 4.0 g of talcum powder was mixed evenly and filled into capsule shells to obtain cefixime capsules.

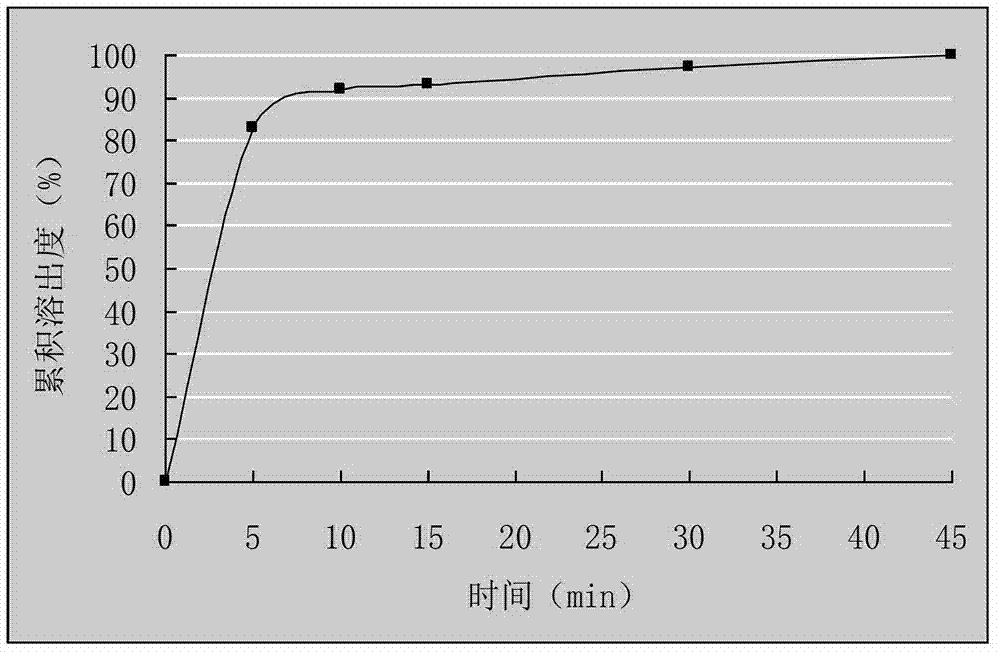

Embodiment 3

[0025] Dissolve 500g of cefixime and 1250g of distearoylphosphatidylcholine in 10L of methanol, add 200g of silicon dioxide, and stir; evaporate the methanol to dryness under reduced pressure below 50°C, take out the evaporated complex, and crush it over 80- 100 mesh sieves to obtain the cefixime phospholipid complex containing silicon dioxide; weigh 195g of the cefixime phospholipid complex containing silicon dioxide, mix it with 180g microcrystalline cellulose, 45g mannitol, and 35g low-substituted hydroxypropyl fiber Dry granulation after uniform mixing, and the obtained dry granules are mixed with 4.0 g of talcum powder and packed into capsule shells to obtain cefixime capsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com