Method for synthesizing N-alkenamide

A technology of alkyl amide and alkyl group, which is applied in the field of synthesizing N-alkyl amide and achieves the effect of broad development prospect and high economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

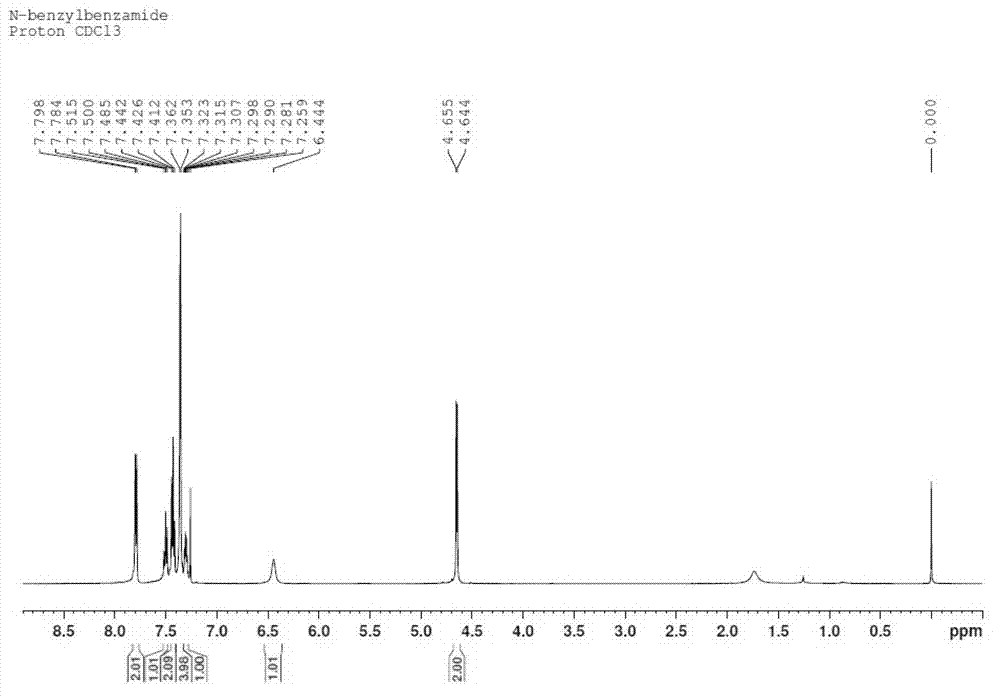

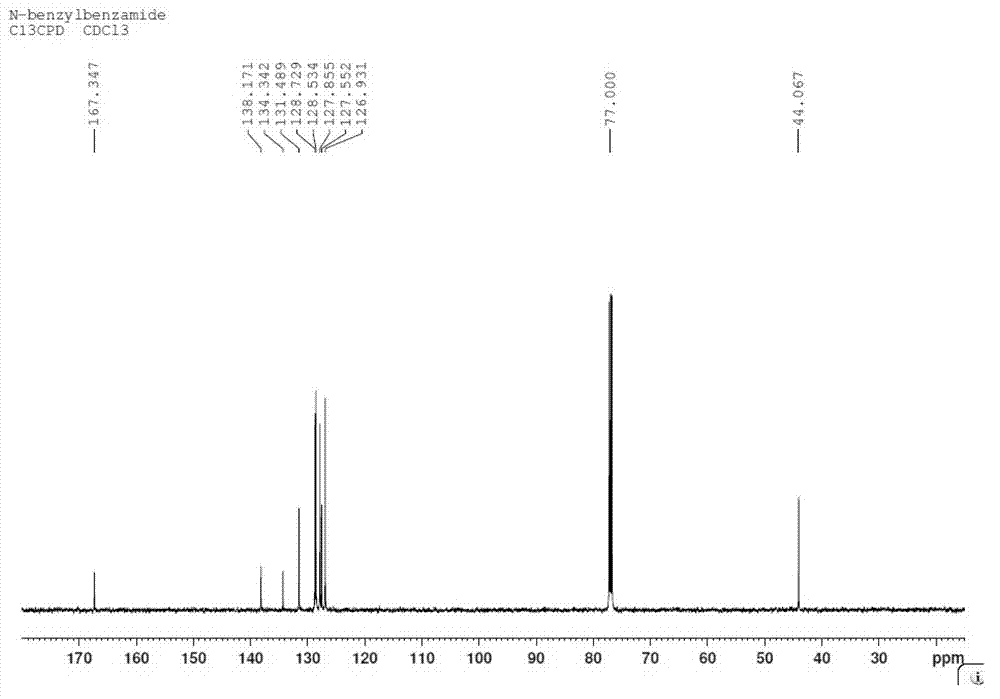

[0032] Embodiment 1: N-benzylbenzamide

[0033] N-benzylbenzamide

[0034]

[0035] Benzaldoxime (121 mg, 1 mmol), [Ru(p-cymene)Cl 2 ] 2 (3.1 mg, 0.005 mmol, 0.5 mol%), [Cp*IrCl 2 ] 2 (4.0 mg , 0.005 mmol, 0.5 mol%), and toluene (1 ml) were sequentially added to a 25 ml Schlenk reaction flask. mixture at 130 o After 3 h at C, cool to room temperature. Benzyl alcohol (130 mg, 1.2 mmol) and cesium carbonate (65 mg, 0.2 equiv.) were added to the reaction flask, and the mixture was o C for another 12 h, then cooled to room temperature. The solvent was removed by rotary evaporation, and then the pure target compound was obtained by column chromatography (developing solvent: ethyl acetate / petroleum ether), the yield: 90%, and its spectrum is as follows figure 1 and 2 shown.

[0036] mp 103-104 o C; 1 H NMR (500 MHz, CDCl 3 ) δ 7.79 (d, J = 7.2 Hz, 2H, ArH), 7.50 (t, J = 7.4 Hz, 1H, ArH), 7.43 (t, J = 7.5 Hz, 2H, ArH), 7.36-7.35 (m, 4H, ArH), 7.32-7.28 (m, 1H, ArH),...

Embodiment 2

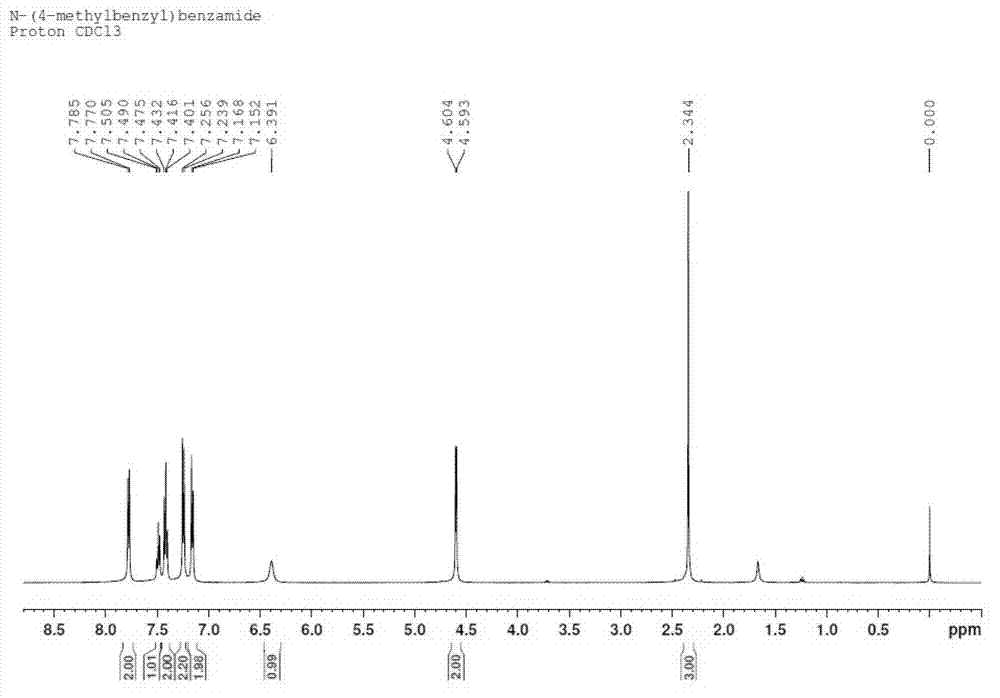

[0037] Embodiment 2: N-(4-methylbenzyl)benzamide

[0038] N-(4-methylbenzyl)benzamide

[0039]

[0040] Benzaldoxime (121 mg, 1 mmol), [Ru(p-cymene)Cl 2 ] 2 (3.1 mg, 0.005 mmol, 0.5 mol%), [Cp*IrCl 2 ] 2 (4.0 mg , 0.005 mmol, 0.5 mol%), and toluene (1 ml) were sequentially added to a 25 ml Schlenk reaction flask. mixture at 130 o After 3 h at C, cool to room temperature. 4-Methylbenzyl alcohol (146 mg, 1.2 mmol) and cesium carbonate (65 mg, 0.2 equiv.) were added to the reaction flask, and the mixture was o C for another 12 h, then cooled to room temperature. The solvent was removed by rotary evaporation, and then the pure target compound was obtained by column chromatography (developing solvent: ethyl acetate / petroleum ether), the yield: 87%, and its spectrum is as follows image 3 and 4 shown.

[0041] mp 142-143 o C; 1 H NMR (500 MHz, CDCl 3 ) δ 7.78 (d, J = 7.3 Hz, 2H, ArH), 7.49 (t, J = 7.4 Hz, 1H, ArH), 7.42 (t, J = 7.6 Hz, 2H, ArH), 7.25 (d, J = 4.3 ...

Embodiment 3

[0042] Embodiment 3: N-(4-isopropylbenzyl)benzamide

[0043] N-(4-isopropylbenzyl)benzamide

[0044]

[0045] Benzaldoxime (121 mg, 1 mmol), [Ru(p-cymene)Cl 2 ] 2 (3.1 mg, 0.005 mmol, 0.5 mol%), [Cp*IrCl 2 ] 2 (4.0 mg , 0.005 mmol, 0.5 mol%), and toluene (1 ml) were sequentially added to a 25 ml Schlenk reaction flask. mixture at 130 o After 3 h at C, cool to room temperature. Add 4-isopropylbenzyl alcohol (180 mg, 1.2 mmol) and cesium carbonate (65 mg, 0.2 equiv.) to the reaction flask, and the mixture is o C for another 12 h, then cooled to room temperature. The solvent was removed by rotary evaporation, and then the pure target compound was obtained by column chromatography (developing solvent: ethyl acetate / petroleum ether) with a yield of 81%.

[0046] mp 103-104 o C; 1 H NMR (500 MHz, CDCl 3 ) δ 7.78 (d, J = 7.2 Hz, 2H, ArH), 7.50 (t, J = 3.8 Hz,1H, ArH), 7.43(t, J = 7.5 Hz, 2H, ArH), 7.30 (d, J = 8.2 Hz, 2H, ArH), 7.22 (d, J = 8.2 Hz, 2H, ArH), 6.36 (b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com