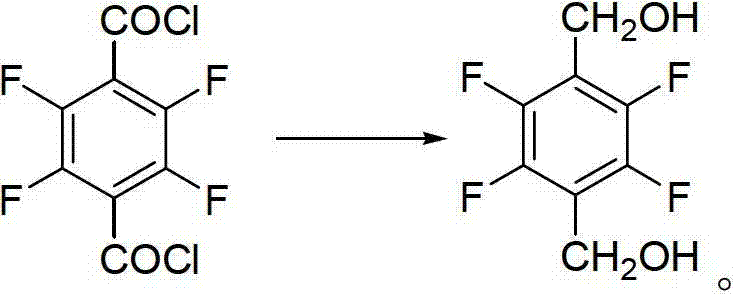

Preparation method of 2,3,5,6-tetrafluoro-1,4-benzenedimethanol

A technology of tetrafluoroterephthaloyl dimethanol and tetrafluoroterephthaloyl chloride, which is applied in the field of preparation of 2,3,5,6-tetrafluoroterephthaloyl dimethanol, can solve the problem of cumbersome post-treatment process, unfavorable industrial production, Solvent is not easy to recover and other problems, to achieve the effect of simple post-treatment process, low cost and easy disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 12

[0019] The preparation of embodiment 12,3,5,6-tetrafluoro-tere-phenylenedimethanol

[0020] Add 7.6g (0.1980mol) of sodium borohydride and 41.3g of chlorobenzene into a 250mL four-neck flask equipped with a thermometer, condenser, and nitrogen protection tube, raise the temperature to 60°C, add 82.5g of chlorobenzene and 27.5g (0.0990mol) of chlorobenzene dropwise The solution of 2,3,5,6-tetrafluoroterephthaloyl chloride was dropped in 0.5 hours. A mixed solution of 2.7 g of chlorobenzene and 0.04 g (0.15 mmol) of iodine was added dropwise, and the drop was completed in 0.5 hours. Incubate at 60°C for 15 hours. Cool down to 50°C, add dropwise to 10% hydrochloric acid aqueous solution by mass percentage (mass percentage refers to the percentage of the mass of hydrogen chloride in the total mass of hydrochloric acid aqueous solution), adjust the pH to 1-2, keep warm for 0.5 hours, and then use a mass percentage of 30 % NaOH aqueous solution (mass percentage refers to the perce...

Embodiment 22

[0021] The preparation of embodiment 22,3,5,6-tetrafluoro-tere-phenylenedimethanol

[0022] Add 9.5g (0.2475mol) of sodium borohydride and 41.3g of chlorobenzene into a 250mL four-neck flask equipped with a thermometer, condenser, and nitrogen protection tube, raise the temperature to 60°C, and add 82.5g of chlorobenzene and 27.5g (0.0990mol) of chlorobenzene dropwise. The solution of 2,3,5,6-tetrafluoroterephthaloyl chloride was dropped in 0.5 hours. A mixed solution of 2.7 g of chlorobenzene and 0.05 g (0.19 mmol) of iodine was added dropwise, and the drop was completed in 0.5 hours. Incubate at 60°C for 8 hours. Cool down to 50°C, add dropwise to 10% hydrochloric acid aqueous solution by mass percentage (mass percentage refers to the percentage of the mass of hydrogen chloride in the total mass of hydrochloric acid aqueous solution), adjust the pH to 1-2, keep warm for 0.5 hours, and then use a mass percentage of 30 % NaOH aqueous solution (mass percentage refers to the p...

Embodiment 32

[0023] The preparation of embodiment 32,3,5,6-tetrafluoro-tere-phenylenedimethanol

[0024] Add 11.4g (0.2970mol) of sodium borohydride and 41.3g of chlorobenzene into a 250mL four-neck flask equipped with a thermometer, condenser, and nitrogen protection tube, raise the temperature to 60°C, and add dropwise 82.5g of chlorobenzene and 27.5g (0.0990mol) The solution of 2,3,5,6-tetrafluoroterephthaloyl chloride was dropped in 0.5 hours. A mixed solution of 2.7 g of chlorobenzene and 0.06 g (0.22 mmol) of iodine was added dropwise, and the drop was completed in 0.5 hours. Incubate at 60°C for 7 hours. Cool down to 50°C, add dropwise to 10% hydrochloric acid aqueous solution (mass percentage refers to the percentage of the mass of hydrogen chloride in the total mass of hydrochloric acid aqueous solution), pH 1 ~ 2, keep warm for 0.5 hours, and then use 30% mass percentage The aqueous solution of NaOH (mass percentage refers to the percentage of the mass of sodium hydroxide in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com