Epoxy-terminated silicon oil modified carboxyl-terminated hyperbranched polyester, and preparation method and application thereof

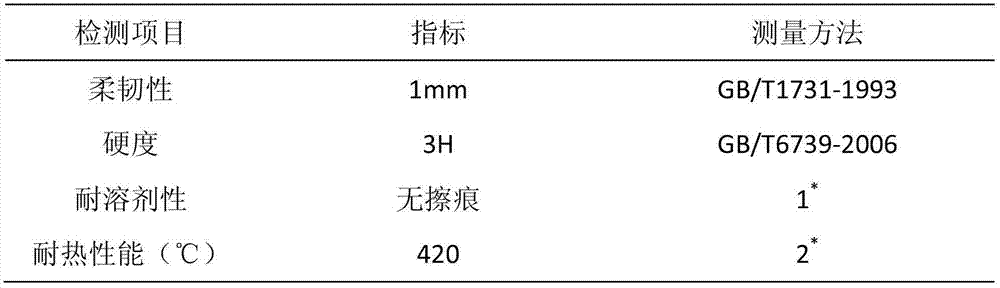

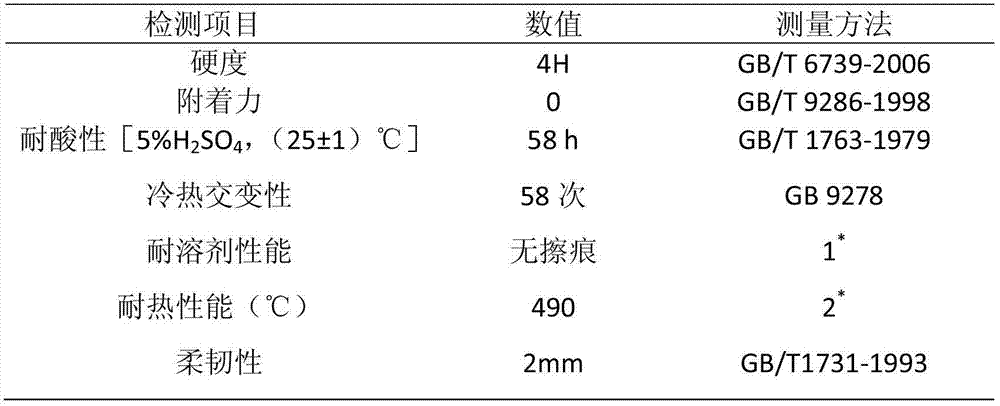

A technology of hyperbranched polyester and epoxy-terminated silicone oil, applied in polyester coatings, coatings, etc., can solve the problems of cracking, poor flexibility of carboxyl-terminated hyperbranched polyester, etc., achieve high heat resistance, improve heat resistance , the effect of good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Preparation of epoxy-terminated silicone oil

[0042] Add 200g of octamethylcyclotetrasiloxane, 0.02g of tetramethylammonium hydroxide and 4g of concentrated sulfuric acid in sequence in proportion to the reactor equipped with a condenser tube, a thermometer, a dropping funnel and a stirrer, and react under nitrogen protection for 7h ; Heating up to 180°C, removing low boilers by distillation under reduced pressure to obtain hydrogen-terminated silicone oil; adding the prepared hydrogen-terminated silicone oil, 2 g of allyl glycidyl ether, 200 g of toluene and 0.02 g of chloroplatinic acid into the reactor; heating up to React at 70°C for 8 hours under nitrogen protection, and distill off the solvent under reduced pressure to obtain epoxy-terminated silicone oil. The weight-average molecular weight of the epoxy-terminated silicone oil is detected by gel permeation chromatography, and the result is 1015; the result is that every 100 g of epoxy-terminated silicone oil ...

Embodiment 2

[0056] 1) Preparation of epoxy-terminated silicone oil

[0057] Add 200 g of octamethylcyclotetrasiloxane, 0.02 g of tetramethylammonium hydroxide, and 4 g of concentrated sulfuric acid in sequence in a reactor equipped with a condenser tube, a thermometer, a dropping funnel, and an agitator, and react under nitrogen protection for 7 h; To 190°C, remove low boilers by distillation under reduced pressure to obtain hydrogen-terminated silicone oil; add the obtained hydrogen-terminated silicone oil, 2g of allyl glycidyl ether, 200g of toluene and 0.02g of chloroplatinic acid into the reactor; heat up to 70°C, nitrogen The reaction was protected for 8.0 h, and the solvent was distilled off under reduced pressure to obtain epoxy-terminated silicone oil.

[0058] The weight-average molecular weight of the epoxy-terminated silicone oil is detected by gel permeation chromatography, and the result is 1015; the epoxy value content of the epoxy-terminated silicone oil is measured by the ...

Embodiment 3

[0071] 1) Preparation of epoxy-terminated silicone oil

[0072] Add 200 g of octamethylcyclotetrasiloxane, 0.06 g of tetramethylammonium hydroxide, and 10 g of concentrated sulfuric acid in sequence in a reactor equipped with a condenser, a thermometer, a dropping funnel, and an agitator, and react under nitrogen protection for 8 hours; To 185°C, remove low boilers by distillation under reduced pressure to obtain hydrogen-terminated silicone oil; add the obtained hydrogen-terminated silicone oil, 18g of allyl glycidyl ether, 350g of toluene and 0.07g of chloroplatinic acid into the reactor; heat up to 80°C, nitrogen The reaction was protected for 9 hours, and the solvent was distilled off under reduced pressure to obtain epoxy-terminated silicone oil.

[0073] The weight-average molecular weight of the epoxy-terminated silicone oil is detected by gel permeation chromatography, and the result is 492; the epoxy value content of the epoxy-terminated silicone oil is measured by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistant | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Heat resistant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com