Biological inhibition method and system of hydrogen sulfide gas in oil gathering system

A gathering and transportation system, bio-suppression technology, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve the problems of temporary but not permanent, environmental pollution, and the treatment effect can only be maintained for a certain period of time, to achieve the elimination of safety. hidden dangers, improve the working environment, reduce the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Take the Aijiawan operating area of Changqing Oilfield as an example. The average concentration of hydrogen sulfide in a single well in the operation area is 260mg / m 3 , the concentration of hydrogen sulfide at the oil transfer station is 263mg / m 3 , the concentration of hydrogen sulfide in the joint station is 5788mg / m 3 .

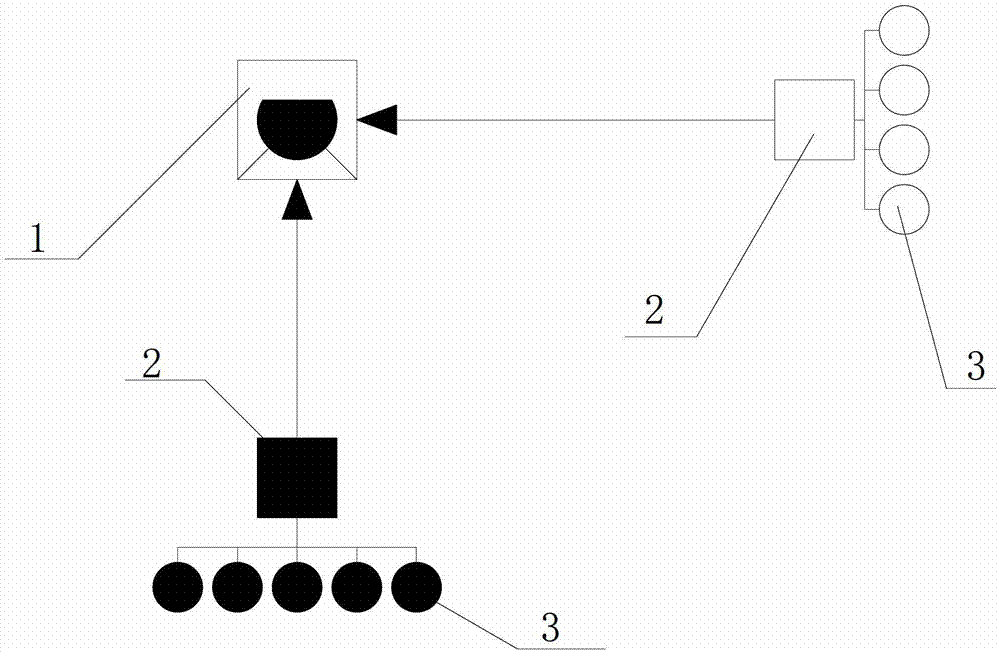

[0049] Such as figure 1 as shown,

[0050] (1) Single well dosing. After calculation, add 60g of embedding pellets to single well 3, after standing for 24 hours, add 100mg / L sodium nitrite corrosion inhibitor, and add 30L MDEA desulfurizer.

[0051] (2) Suppression of oil transfer stations. Add 50g of synchronous desulfurization and denitrification embedding pellets to oil transfer station 2, add 100mg / L sodium nitrite after 24 hours; add 20L1moL / L NaOH solution;

[0052](3) Combined station suppression. Add 100g of synchronous desulfurization and denitrification embedding pellets to joint station 1, and add 100mg / L sodium nitrite after 2...

Embodiment 2

[0055] Take the Pengyang operation area of Changqing Oilfield as an example. The average hydrogen sulfide concentration of a single well in the operation area is 310mg / L, and the hydrogen sulfide concentration at the oil transfer station is 410mg / m 3 , the concentration of hydrogen sulfide in the joint station is 3107mg / m 3 .

[0056] Such as figure 1 as shown,

[0057] (1) Single well dosing. After calculation, add 60g of embedding pellets to single well 3, after standing for 24 hours, add 100mg / L sodium nitrite corrosion inhibitor, and add 30L MDEA desulfurizer.

[0058] (2) Suppression of oil transfer stations. Add 50g of synchronous desulfurization and denitrification embedding pellets to oil transfer station 2, add 100mg / L sodium nitrite after 24 hours; add 20L1moL / L NaOH solution;

[0059] (3) Combined station suppression. Add 100g of synchronous desulfurization and denitrification embedding pellets to joint station 1, and add 100mg / L sodium nitrite after 24 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com