Colored photosensitive resin composition, color filter and display device

A photosensitive resin and composition technology, applied in the field of color filters and display devices, and colored photosensitive resin compositions, can solve the problems of insoluble, incapable of making high-contrast color filters, etc., and achieve excellent stability over time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] After mixing each of the following components and stirring the mixture for 1 hour, it filtered through a 5 μm membrane filter to prepare a colored photosensitive resin composition.

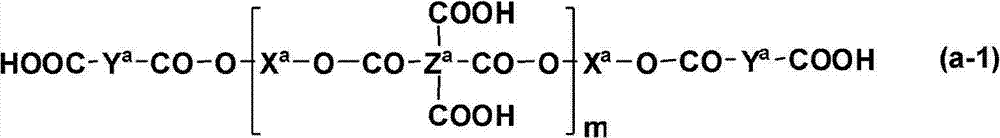

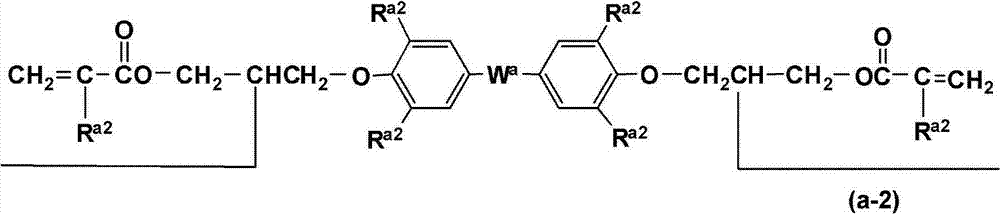

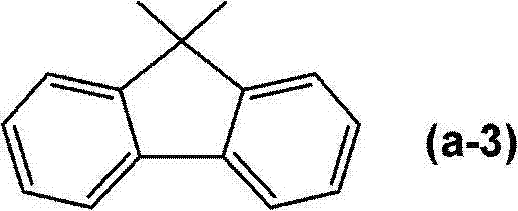

[0079] · Alkali soluble resin

[0080] Resin A (solid content 55%, solvent: 3-methoxybutyl acetate)

[0081] …60 parts by mass

[0082] ·Photopolymerizable monomer

[0083] Dipentaerythritol hexaacrylate (manufactured by Nippon Kayaku Co., Ltd.)...25 parts by mass

[0084] ·Photopolymerization Initiator

[0085] 1-[9-Ethyl-6-(2-methylbenzoyl)-9H-carbazol-3-yl]-ethanone-1-(O-acetyloxime) "IRGACURE OXE-02" (trade name : Made by BASF Corporation)

[0086] …15 parts by mass

[0087] ·Inorganic pigments

[0088] Carbon dispersion liquid "CF BLACK" (trade name: manufactured by Mikuni Color Co., Ltd., solid content 25% Solvent: 3-methoxybutyl acetate ... 400 parts by mass

[0089] ·Solvent

[0090] 3-methoxybutyl acetate / 1,1,3,3-tetramethylurea / propylene glycol monomethyl acetate=55 / 10 / 35...

Embodiment 2~10 and comparative example 1~9

[0098] Except having changed the mixing ratio (mass ratio) of a solvent as shown in Table 1, it carried out similarly to Example 1, and prepared the colored photosensitive resin composition.

[0099] [Table 1]

[0100]

[0101] MBA: 3-methoxybutyl acetate

[0102] PGME A: Propylene Glycol Monomethyl Ether Acetate

[0103] EL: ethyl lactate

[0104] Ethyl Cellosolve: Ethylene Glycol Monoethyl Ether

[0105] AN: Cyclohexanone

[0106] γ-BL: γ-butyrolactone

[0107] δ-VL: δ-valerolactone

[0108] ε-CL: ε-caprolactone

[0109] TMU: 1,1,3,3-Tetramethylurea

[0110] DMF: Dimethylformamide

[0111] DMAC: Dimethylacetamide

[0112] DMI: 1,3-Dimethyl-2-imidazolinone

[0113]

[0114] [Evaluation of Viscosity Stability]

[0115] About the colored photosensitive resin composition of Examples 1-10 and Comparative Examples 1-9, the viscosity was measured using the E-type viscometer at the initial stage of preparation and after storage at 25 degreeC for 7 days, and the visco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com