Neodymium iron boron magnet made of neodymium iron boron nickel-plating waste materials in sintered mode

A technology of NdFeB and nickel plating, applied in the field of rare earth magnetic materials, can solve the problems of difficult to meet high requirements, low utilization rate of NdFeB waste, poor performance of NdFeB magnets, etc., and achieve low weight loss rate , Improved milling efficiency and good temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

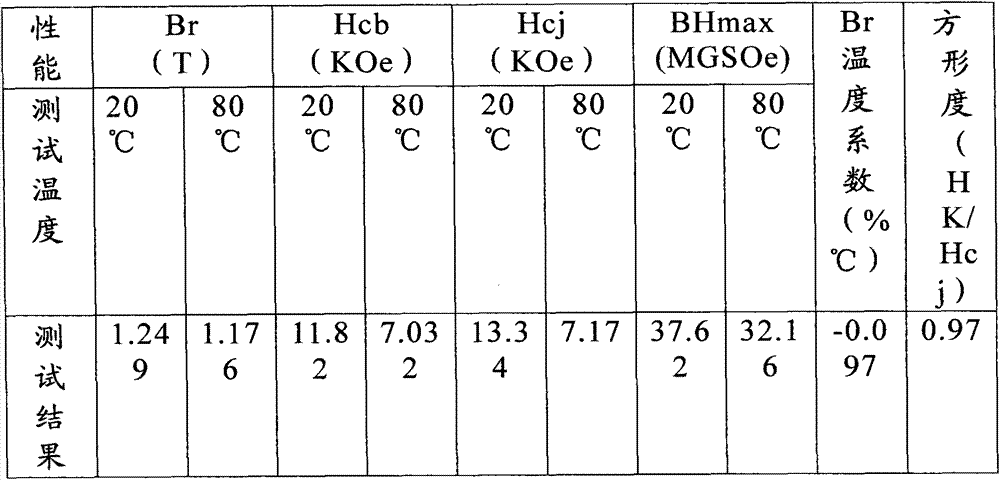

[0030] Production of N38 products using NdFeB nickel plating waste:

[0031] Roasting NdFeB nickel-plated waste: put the NdFeB nickel-plated waste in a sintering furnace, and heat up to 1100°C for roasting. The vacuum degree in the sintering furnace is less than 10 -1 Pa, the roasting time is 4 hours, then filled with nitrogen, fan cooling, until the temperature drops below 80 ° C, out of the furnace.

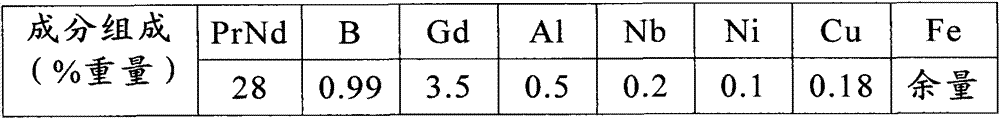

[0032] Preparation of NdFeB nickel-plating waste powder: put 600kg of roasted NdFeB nickel-plating waste into a vacuum quick-setting furnace for melting, and start heating and melting when the air in the furnace is pumped to a vacuum degree of 0.4Pa. When the material in the furnace turns red, fill it with argon, and heat up to 1450°C for smelting until the NdFeB nickel-plated waste is completely melted. Refined for 10 minutes and poured into flakes. The flakes were subjected to ICP component determination, and the component determination results are shown in Table 1. Then ...

Embodiment 2

[0049] Production of 35SH products with NdFeB nickel plating waste:

[0050] Roasting NdFeB nickel-plated waste: put the NdFeB nickel-plated waste in a sintering furnace, and heat up to 1120°C for roasting. The vacuum in the sintering furnace is lower than 10 -1 Pa, the roasting time is 4 hours, then filled with nitrogen, fan cooling, until the temperature drops below 80 ° C, out of the furnace.

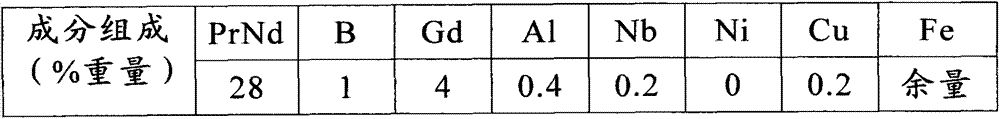

[0051] Preparation of NdFeB nickel-plating waste powder: Mix 600kg of roasted NdFeB nickel-plating waste and put it into a vacuum quick-setting furnace for smelting. When the air in the furnace is pumped to a vacuum of 0.4Pa, heating and smelting begins. When the material in the furnace turns red, fill it with argon, and heat up to 1500°C for melting until the NdFeB nickel-plated waste is completely melted. Refined for 10 minutes and poured into flakes. The flakes were subjected to ICP composition determination, and the composition measurement results are shown in Table 5. Then p...

Embodiment 3

[0068] Production of 45H products with NdFeB nickel plating waste:

[0069] Roasting NdFeB nickel-plated waste: put the NdFeB nickel-plated waste in a sintering furnace, and heat up to 1130°C for roasting. The vacuum in the sintering furnace is lower than 10 -1 Pa, the roasting time is 4 hours, then filled with nitrogen, fan cooling, until the temperature drops below 80 ° C, out of the furnace.

[0070] Preparation of NdFeB nickel-plating waste powder: Mix 600kg of roasted NdFeB nickel-plating waste and put it into a vacuum quick-setting furnace for smelting. When the air in the furnace is pumped to a vacuum of 0.4Pa, heating and smelting begins. When the material in the furnace turns red, fill it with argon, and heat up to 1500°C for melting until the NdFeB nickel-plated waste is completely melted. Refined for 10 minutes and poured into flakes. The flakes were subjected to ICP composition determination, and the composition measurement results are shown in Table 9. Then pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Residual magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com