Method for growing Gaas material hemt device in art structure trench

An in-growth and trench technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems affecting the quality of epitaxial layers, and achieve the effect of reducing defects, improving device quality, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

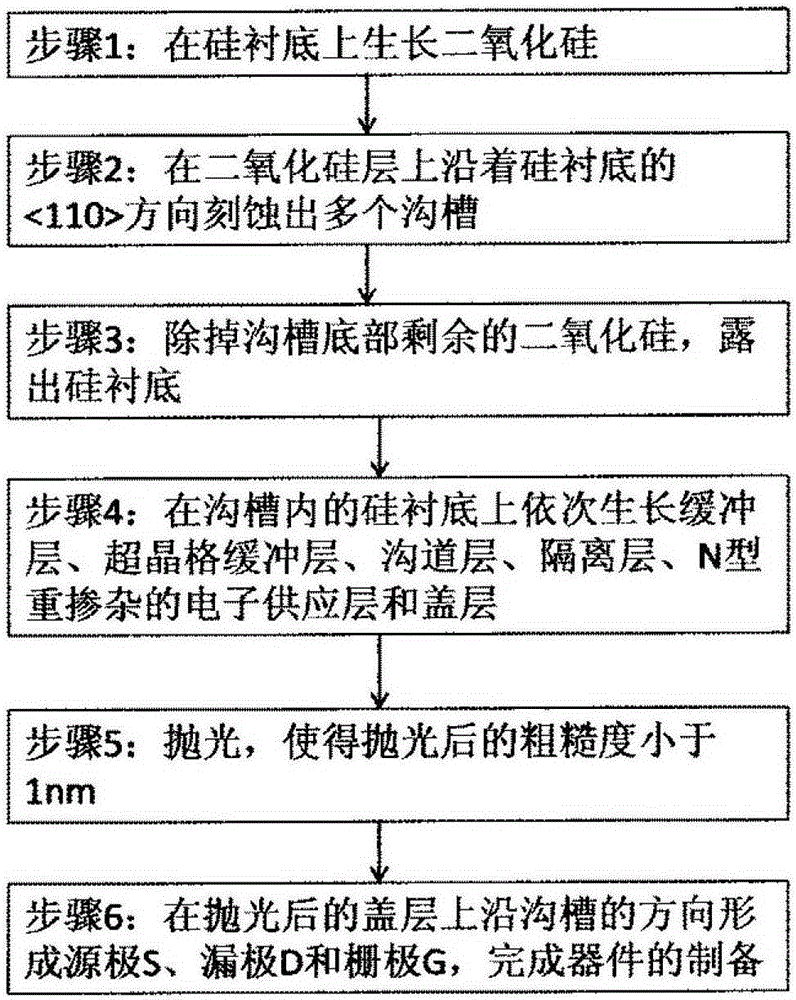

[0019] see figure 1 , and see Figure 2 to Figure 7 The present invention provides a method for growing a GaAs material HEMT device in an ART structure trench, comprising the following steps:

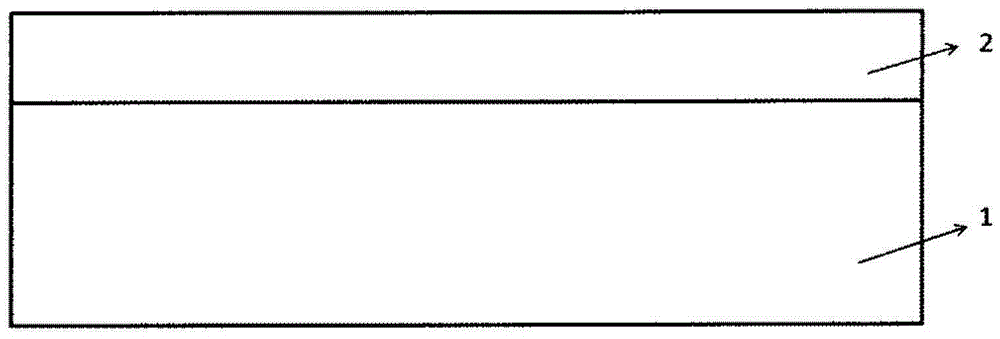

[0020] Step 1: grow silicon dioxide layer 2 on silicon substrate 1 (see figure 2 ), the thickness of the silicon dioxide layer 2 is 600-700nm, and the preferred thickness is 600nm; when growing, we choose a Si substrate with a certain off angle (6°-7°), which can limit the antiphase domain ( APD) formation. At the same time, using high aspect ratio confinement technology, using SiO with AR>1 2 Trench to better confine fitting dislocations and APD formation.

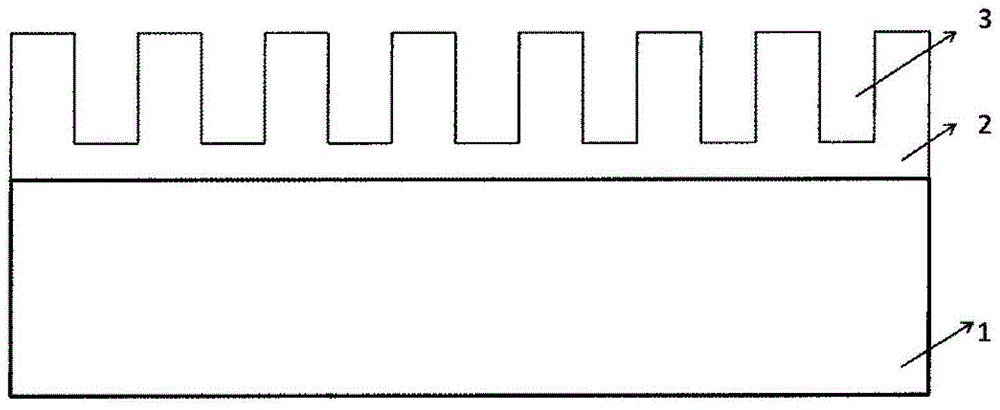

[0021] Step 2: Etch a plurality of trenches 3 along the direction of the silicon substrate 1 on the silicon dioxide layer 2 by holographic exposure and ICP (see image 3 ), the width of the trench 3 is 200-300nm, and the depth is the same as the thickness of the silicon dioxide layer 2; in SiO 2 In the trench, epitaxial GaA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com