Method for preparing rice hull ash active carbon from solid-state co-fermentation rice hull

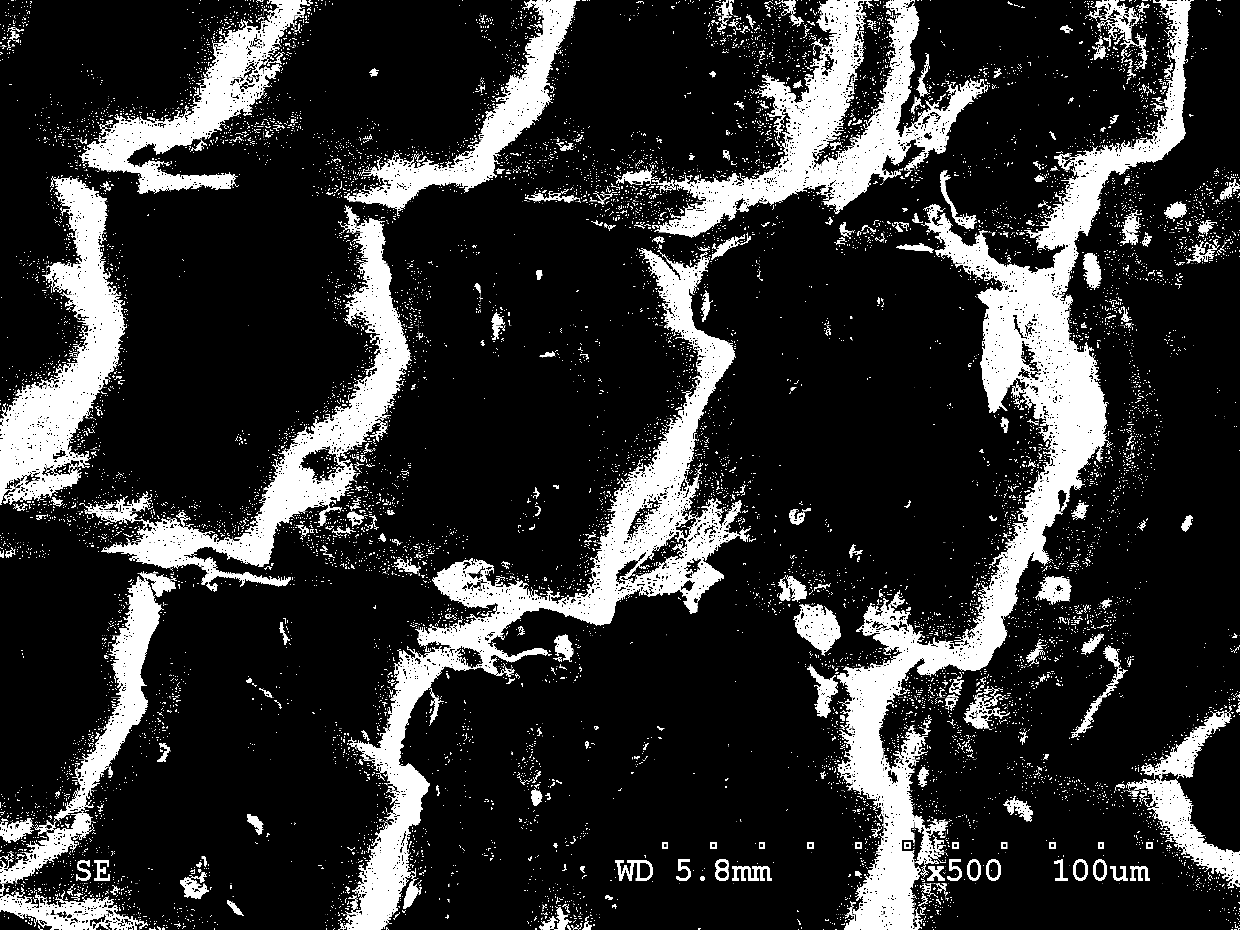

A technology of solid-state fermentation and activated carbon, applied in chemical instruments and methods, solid waste removal, carbon compounds, etc., to achieve the effects of good surface micropore structure, easy operation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Prepare rice husk ash activated carbon according to the following steps

[0017] In the first step, the white rot fungus was inserted into the rice husk fermentation medium and fermented at 25℃ for 9 days to obtain the fermentation substrate; the water content of the medium was 30%, and the inoculum was the spore suspension concentration of 10 7 cfu / mL, the inoculation volume is 5%; among them, the rice husk fermentation medium is composed of the following components by weight percentage: rice husk 10%, ammonium sulfate 3.0%, potassium dihydrogen phosphate 3.0%, magnesium sulfate 3.0%, Tween- 80 3.0%, pH4, the rest water;

[0018] In the second step, insert Trichoderma viride into the fermentation substrate of step 1, and ferment for 7 days at a temperature of 25°C. The inoculum is the spore suspension concentration of 10 7 cfu / mL, the inoculation volume is 5%;

[0019] The third step is carbonization to prepare rice husk ash activated carbon: firstly, the rice husk...

Embodiment 2

[0020] Example 2: Prepare rice husk ash activated carbon according to the following steps

[0021] In the first step, the white rot fungus is connected to the rice husk fermentation medium and fermented at 30℃ for 6 days to obtain the fermentation substrate; the water content of the medium is 55%, and the inoculum is 0.5×10. 7 cfu / mL, the inoculation volume is 15%; among them, the rice husk fermentation medium is composed of the following components by weight percentage: rice husk 15%, ammonium sulfate 1.75%, potassium dihydrogen phosphate 1.7%, magnesium sulfate 1.75%, Tween- 80 1.75%, pH 5.0, the rest is water;

[0022] In the second step, insert Aspergillus niger into the fermentation substrate of step 1, and ferment for 4 days at a temperature of 30°C. The inoculum amount is 0.5×10 spore suspension. 7 cfu / mL, the inoculation volume is 15%;

[0023] The third step is carbonization to prepare rice husk ash activated carbon: firstly, the rice husk treated in step two is dehydrated a...

Embodiment 3

[0024] Example 3: Prepare rice husk ash activated carbon according to the following steps

[0025] In the first step, the white rot fungus is connected to the rice husk fermentation medium and fermented at 35℃ for 3 days to obtain the fermentation substrate; the water content of the medium is 80%, and the inoculum is the spore suspension concentration of 10 8 cfu / mL, the inoculum volume is 25%; among them, the rice husk fermentation medium is composed of the following components by weight percentage: rice husk 20%, ammonium sulfate 0.5%, potassium dihydrogen phosphate 0.5%, magnesium sulfate 0.5%, Tween -80 0.5%, pH 6.5, the rest is water;

[0026] In the second step, insert Trichoderma reesei into the fermentation substrate of step 1, and ferment for 1 d at a temperature of 35°C. The inoculum is the spore suspension concentration of 10 8 cfu / mL, the inoculation volume is 25%;

[0027] The third step is carbonization to prepare rice husk ash activated carbon: firstly, the rice husk t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com