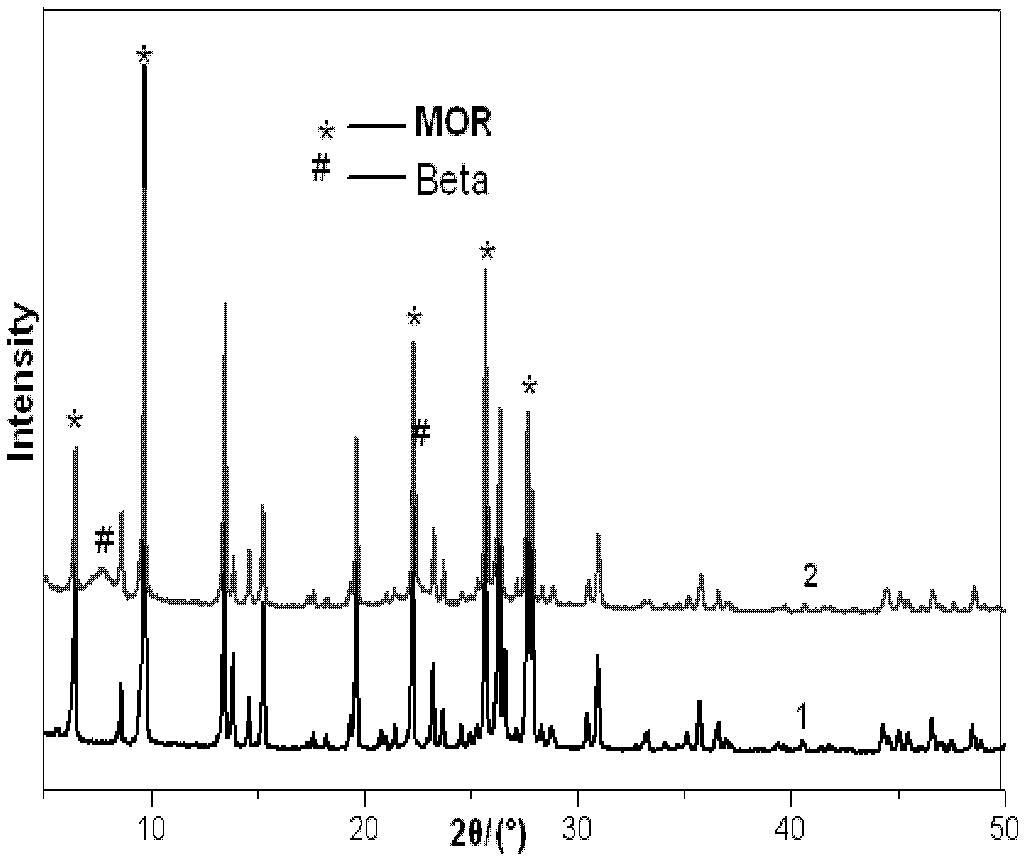

Preparation method of core-shell molecular sieve MOR/BEA (mordenite/bromoethylamine)

A core-shell molecular sieve and molecular sieve technology, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of high product shell coverage, low core-shell molecular sieve shell coverage, and low synthesis cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

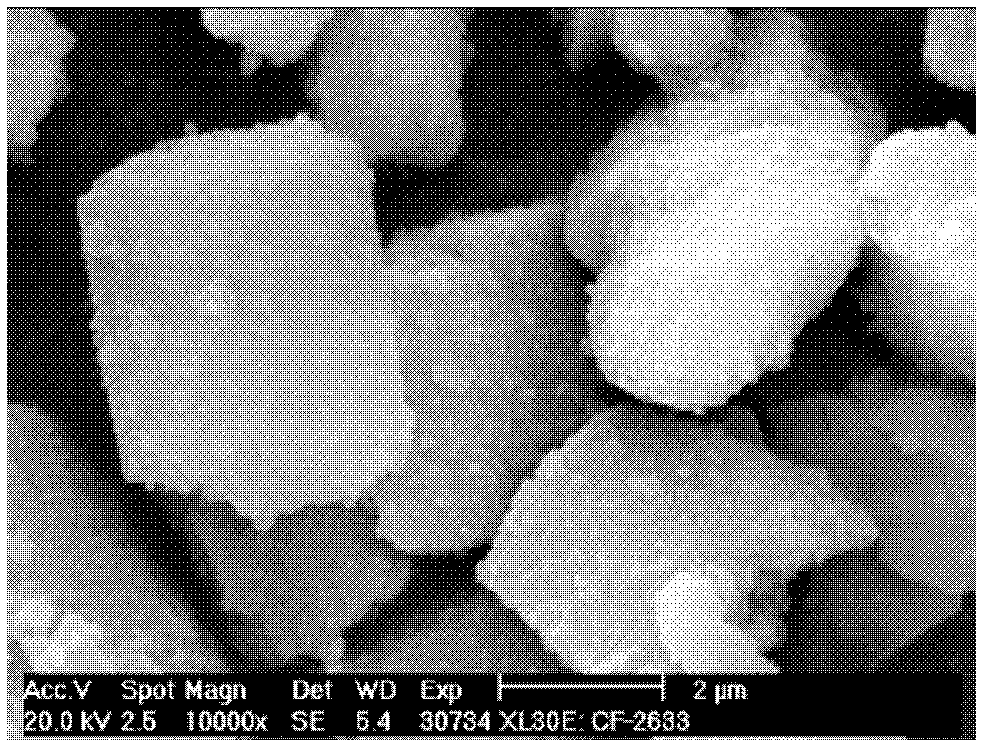

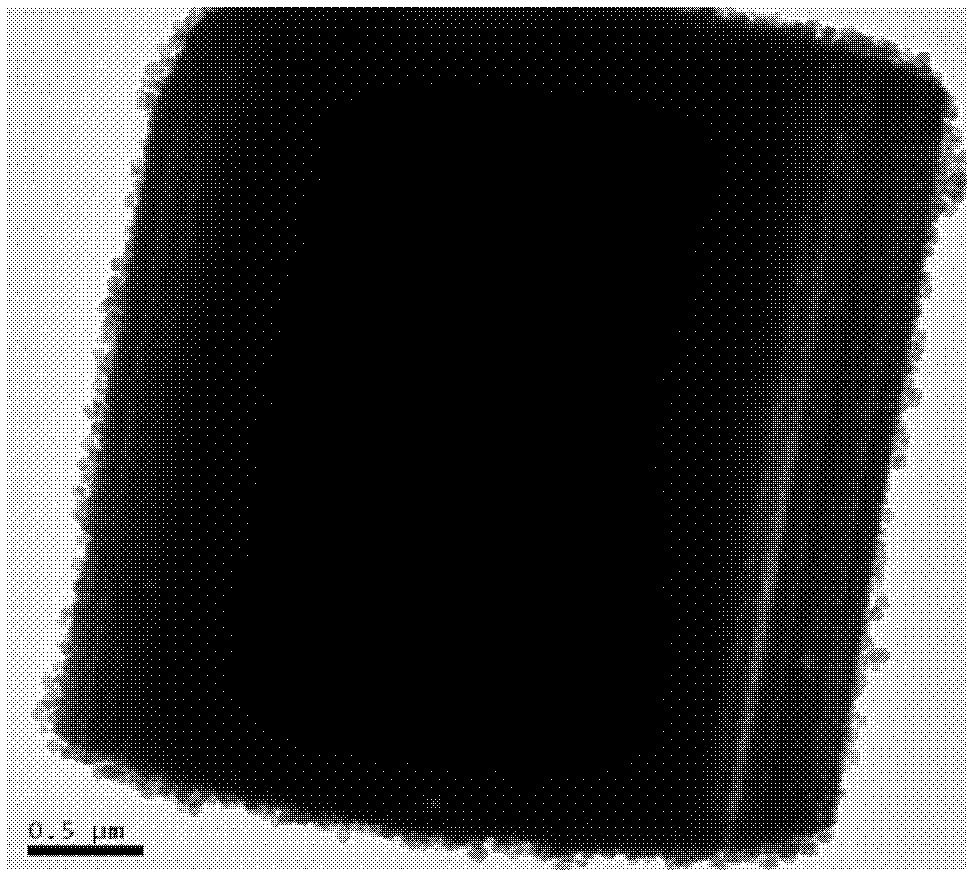

Embodiment 1

[0022] Concrete reactant proportioning and experimental method are as follows:

[0023] Ratio of reactants in nuclei seed: 7Na 2 O: 2.5NaF: 1Al 2 o 3 : 30SiO 2 : 360H 2 o

[0024] The reactant ratio of β nanocrystal: 13(TEA) 2 O: 1Al 2 o 3 : 66SiO 2 : 780H 2 o

[0025] Ratio of reactants for secondary growth of core-shell: 13(TEA) 2 O: 1Al 2 o 3 : 71.4SiO2 2 : 2286H 2 o

[0026] 112.5 grams of silica sol (40%wt) and 2.628 grams of NaF were dissolved in 40 grams of deionized water to configure solution A; 4.1 grams of NaAlO 2 and 12.0 grams of NaOH were dissolved in 50 grams of deionized water to prepare solution B. Slowly add solution B dropwise to solution A, stir well, and crystallize the formed reaction mixture at 170°C for 3 days to obtain large-grain nuclei-phase mordenite I, with a measured fluorine content of 614 μg / g, silicon-alumina The ratio is 20.4.

[0027] 30 grams of white carbon black and 110 grams of tetraethylammonium hydroxide solution (mas...

Embodiment 2~6

[0033] Examples 2-6 are based on the synthesis ratio and synthesis conditions in Table 1, and are synthesized according to the method and steps similar to Example 1 to obtain core-shell molecular sieves CFS2-6#, see Table 1 for details.

Embodiment 7

[0035] Concrete reactant proportioning and experimental method are as follows:

[0036] Nucleus phase seed: industrial MOR (fluorine content 2 / Al 2 o 3 =22.6)

[0037] The reactant ratio of β nanocrystal: 13(TEA) 2 O: 1Al 2 o 3 : 66SiO 2 : 780H 2 o

[0038] Ratio of reactants for secondary growth of core-shell: 13(TEA) 2 O: 1Al 2 o 3 : 71.4SiO2 2 : 2286H 2 O Dissolve 3 g of PDDA (35% wt), 4.5 g of ammonia solution (25% wt) in 142.5 g of NaCl deionized water (0.1 mol / L) and stir evenly, 30 g of industrial MOR is added to this surface as a nuclear phase molecular sieve In the modifier solution, stir and keep at room temperature for 1 hour, filter and dry in the air atmosphere at 60°C, add to the beta zeolite nanocrystal suspension for pre-adhesion for 90 minutes, filter and dry in the air atmosphere at 100°C That is, the processed MOR powder is obtained. 4 grams of white carbon black, 0.765 grams of sodium aluminate, 14.137 grams of tetraethylammonium hydroxide so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com