Production method of liquid milk

A production method and liquid milk technology, applied in milk preparations, dairy products, applications, etc., can solve problems such as milk floating and sedimentation, excessive black grain proportion, and loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

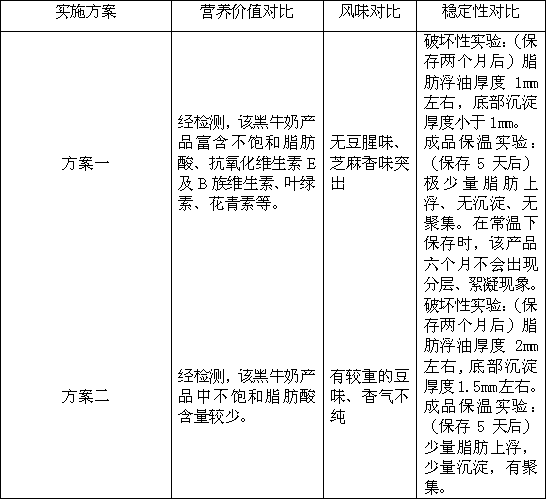

Examples

Embodiment 1

[0031] A method for producing liquid milk is carried out in the following steps:

[0032] a. Wash the black sesame seeds with 0.5% of the total mass and black beans with 0.5% of the total mass to refining with water, the refining temperature is 98°C, and the mass ratio of black sesame and black beans to water is 1:12;

[0033] b. Black rice noodles refined to more than 100 mesh and 2% of the total mass are mixed with the above-mentioned black sesame and black soybean thick liquid, matured, homogenized, deodorized, and sterilized to prepare a black grain base material; the curing temperature is 95 ℃, time is 17 minutes, homogenization temperature is 52℃, pressure is 46Mpa.

[0034] c. Add the above-mentioned black cereal base material to low-fat emulsion milk with a mass percentage of 86%, add fructo-oligosaccharides with a mass percentage of 6% and xanthan gum with a mass percentage of 0.4%. Perform secondary homogenization at a temperature of 68°C and a pressure of 29Mpa;

[0035...

Embodiment 2

[0038] A method for producing liquid milk is carried out in the following steps:

[0039] a. Wash the black sesame seeds with a mass percentage of 3% and black soybeans with a mass percentage of 0.5% and refining with water. The refining temperature is 85°C, and the mass ratio of black sesame and black beans to water is 1:10;

[0040] b. Black rice flour refined to 150 mesh or more and 0.5% of the total mass is mixed with the above-mentioned black sesame and black soybean thick liquid, matured, homogenized, deodorized, and sterilized to make a black grain base material; the curing temperature is 85 ℃, time is 20 minutes, homogenization temperature is 58℃, pressure is 26Mpa.

[0041] c. The above-mentioned black cereal base material is added to the skimmed emulsion milk with a mass percentage of 84%, and the fructo-oligosaccharide with a mass percentage of 3% and an emulsification stabilizer with a mass percentage of 0.1% are mixed. The emulsion stabilizer is composed of microcrys...

Embodiment 3

[0045] A method for producing liquid milk is carried out in the following steps:

[0046] a. Wash the black sesame seeds with a mass percentage of 1.2% and black soybeans with a mass percentage of 0.6% and refining with water. The refining temperature is 90°C and the mass ratio of black sesame and black beans to water is 1:9;

[0047] b. The black rice flour with a mass percentage of 0.6% of the total amount is mixed with the black sesame and black soybean thick liquid, matured, homogenized, deodorized at 0.05Mpa, and sterilized at 120-150°C to prepare a black cereal base material; the curing temperature is 82 ℃, time is 22-25 minutes, homogenization temperature is 55℃, pressure is 24Mpa;

[0048] c. The above-mentioned black cereal base material is added to the full-fat emulsion milk with a mass percentage of 83% of the total, white granulated sugar with a mass percentage of 5% and an emulsion stabilizer with a mass percentage of 0.2% are mixed. The emulsion stabilizer is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com