Foaming agent for earth pressure balance shield machine

An earth pressure balance and shield machine technology, which is applied in the field of special foaming agent for earth pressure balance shield machine construction, can solve the problems of eccentric wear or extreme wear of the cutter ring, reduced cutter head torque, and reduced propulsion speed, etc. Achieve the effect of slowing tool wear, reducing cutter head torque, and improving flow plastic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

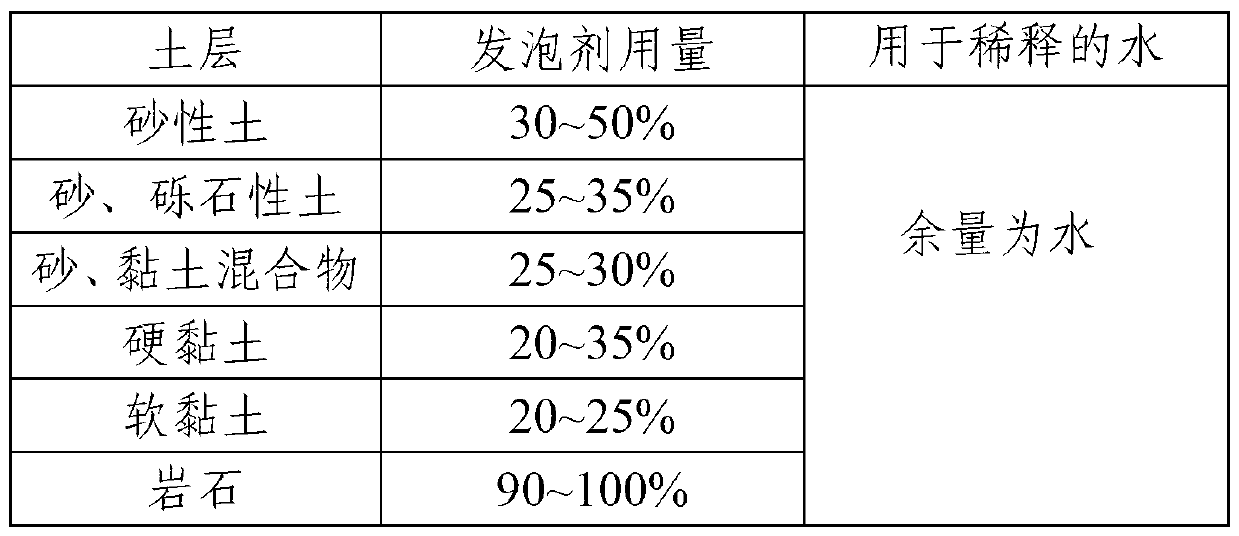

Method used

Image

Examples

Embodiment 1

[0059] In this embodiment, the special foaming agent for the earth pressure balance shield machine is calculated by weight percentage and consists of the following ingredients: 6% fatty alcohol polyoxyethylene ether sodium sulfate that plays a foaming role,

[0060] Fatty acid diethanolamide 3% with thickening, foaming and foam stabilizing effects,

[0061] Lauramide propylamine oxide 3% for foaming and foam stabilization,

[0062] Fatty alcohol sodium sulfate 4% for foaming, emulsifying and dispersing,

[0063] Methylchloroisothiazolinone 0.2% as a preservative,

[0064] Disodium edetate 0.1%, which acts as a water quality stabilizer,

[0065] The above components are indispensable, and the rest is 83.7% of deionized water.

[0066] At room temperature, mix and stir the components evenly to make a foaming agent. The physical and chemical indicators of the foaming agent are

[0067] project

Physical and chemical indicators

Exterior

colorless trans...

Embodiment 2

[0071] In this embodiment, the special foaming agent for the earth pressure balance shield machine is calculated by weight percentage and consists of the following ingredients: 12% fatty alcohol polyoxyethylene ether sodium sulfate that plays a foaming role,

[0072] Fatty acid diethanolamide 3% with thickening, foaming and foam stabilizing effects,

[0073] Lauramide propylamine oxide 3% for foaming and foam stabilization,

[0074] Fatty alcohol sodium sulfate 4% for foaming, emulsifying and dispersing,

[0075]Methylchloroisothiazolinone 0.2% as a preservative,

[0076] Disodium edetate 0.1%, which acts as a water quality stabilizer,

[0077] Deionized water 77.7%.

[0078] The physicochemical index of the whipping agent after mixing is identical with embodiment one.

Embodiment 3

[0080] In this embodiment, the special foaming agent for the earth pressure balance shield machine is calculated by weight percentage and consists of the following ingredients: 9% fatty alcohol polyoxyethylene ether sodium sulfate that plays a foaming role,

[0081] Fatty acid diethanolamide 3% with thickening, foaming and foam stabilizing effects,

[0082] Lauramide propylamine oxide 4% for foaming and foam stabilization,

[0083] Sodium fatty alcohol sulfate 5% for foaming, emulsifying and dispersing,

[0084] Methylchloroisothiazolinone 0.3% as a preservative,

[0085] Disodium edetate 0.2% which acts as a water quality stabilizer,

[0086] Deionized water 78.5%.

[0087] The physicochemical index of the whipping agent after mixing is identical with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com