High-performance environmentally-friendly flame retardant type organic electron pouring sealant and preparation method thereof

A flame-retardant and silicone technology, which is applied in the field of environmentally friendly flame-retardant silicone electronic potting adhesive and its preparation, can solve the problems of difficult electronic component potting, high viscosity of potting glue, and high viscosity of rubber material, etc. , to achieve the effect of ensuring mechanical properties, good fluidity and moderate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

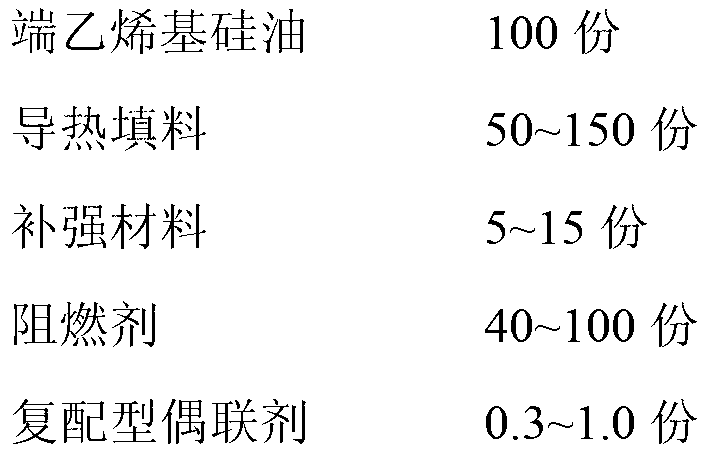

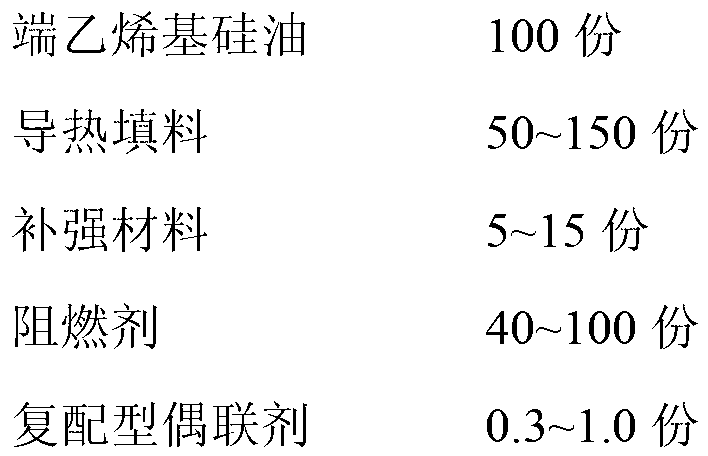

Method used

Image

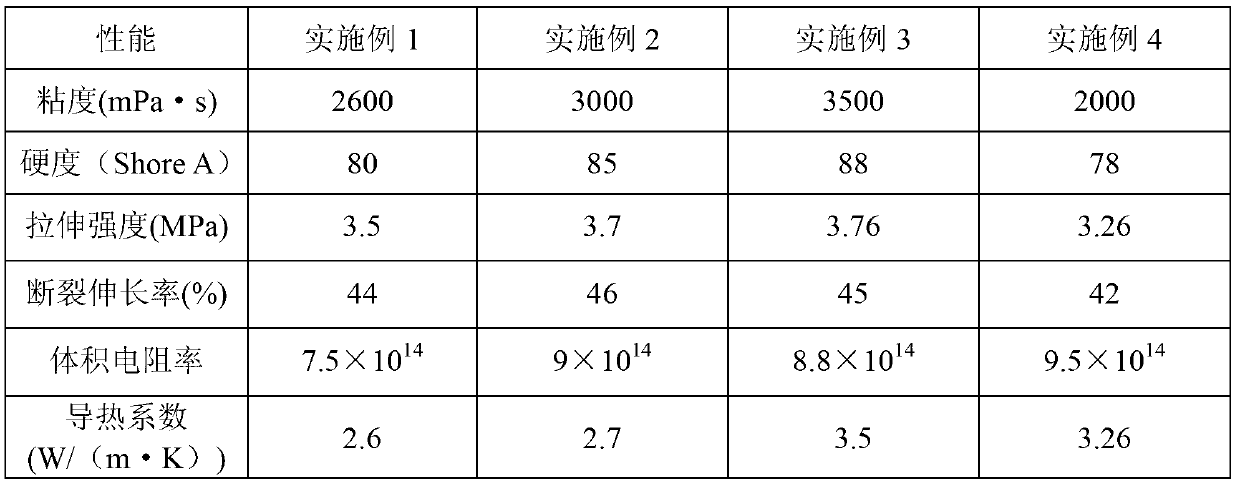

Examples

Embodiment 1

[0034] 1) Preparation of base material: Add 100 parts by weight of vinyl-terminated silicone oil, 50 parts by weight of thermally conductive filler, 5 parts by weight of reinforcing material and 40 parts by weight of flame retardant into a vacuum kneader. Under the condition of vacuum degree of 0.06~0.1MPa, add dropwise 0.3 parts by weight of compound coupling agent diluted with ethanol alcohol solution of water to it while stirring, then dehydrate and blend for 2 hours, cool and grind for 3 Obtain the base material for the first time;

[0035]Wherein, the vinyl-terminated silicone oil is a branched-chain vinyl-terminated silicone oil with a viscosity of 1000mPa·s (vinyl content is 0.1wt%) and a straight-chain vinyl-terminated silicone oil with a viscosity of 300mPa·s in a mass ratio of 7:2. (vinyl content is 0.1wt%); the thermally conductive filler is a mixture of alumina with a particle size of 1.6 μm and silicon micropowder with a particle size of 5 μm at a mass ratio of 1:...

Embodiment 2

[0040] 1) Preparation of base material: Add 100 parts by weight of vinyl-terminated silicone oil, 150 parts by weight of thermally conductive filler, 15 parts by weight of reinforcing material and 100 parts by weight of flame retardant into a vacuum kneader. Under the condition of vacuum degree of 0.06~0.1MPa, 1.0 parts by weight of compound coupling agent diluted with ethanol-alcohol solution of water was added dropwise to it while stirring, and then dehydrated and blended for 5 hours, and after cooling, it was ground with a three-roll machine for 4 Obtain the base material for the first time;

[0041] Wherein, the vinyl-terminated silicone oil is a branched-chain vinyl-terminated silicone oil with a viscosity of 1500mPa·s (vinyl content is 0.6wt%) and a straight-chain vinyl-terminated silicone oil with a viscosity of 600mPa·s in a mass ratio of 7:5. (vinyl content is 0.3wt%); the thermally conductive filler is a mixture of alumina with a particle size of 1 μm and silicon mic...

Embodiment 3

[0046] 1) Preparation of base material: Add 100 parts by weight of vinyl-terminated silicone oil, 100 parts by weight of thermally conductive filler, 10 parts by weight of reinforcing material and 70 parts by weight of flame retardant into a vacuum kneader, at 130°C, Under the condition of vacuum degree of 0.06~0.1MPa, 0.6 parts by weight of compound coupling agent diluted with ethanol alcohol solution of water was added dropwise to it while stirring, and then dehydrated and blended for 4 hours, cooled and ground with a three-roll machine for 3 Obtain the base material for the first time;

[0047] Wherein, the vinyl-terminated silicone oil is a branched-chain vinyl-terminated silicone oil with a viscosity of 1200mPa·s (vinyl content is 1wt%) and a straight-chain vinyl-terminated silicone oil with a viscosity of 500mPa·s in a mass ratio of 7:4 ( vinyl content is 0.5wt%); the thermally conductive filler is mixed with alumina with a particle size of 10 μm and silicon micropowder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com