Method for improving electric conductivity of amorphous silicon membrane

A technology of amorphous silicon thin film and conductivity, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of few direct use and poor material performance, achieve good light absorption characteristics, improve Effect of conductivity, high temperature coefficient of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

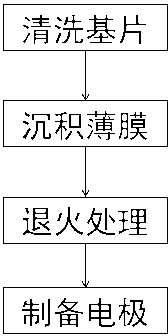

[0036] Step 1: Use K9 slide as substrate. Wipe the substrate with detergent and rinse with deionized water. Put the substrate into a container filled with acetone (analytical grade), put the container into an ultrasonic cleaner, ultrasonically clean it for 15 minutes, and then rinse the substrate with deionized water. Based on the same method, continue to use ethanol (analytical grade) and deionized water to clean the substrate in sequence. Put the cleaned substrate into a container filled with deionized water.

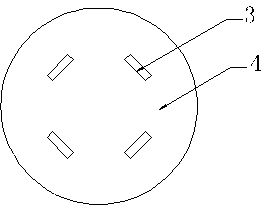

[0037] Step 2: Using a silicon-ruthenium composite target with a diameter of 100mm and a thickness of 3mm, six pure ruthenium blocks with a size of 4mm×15mm×1mm are symmetrically inlaid on the sputtering track of the silicon target; the area of the ruthenium block and the sputtering track of the silicon target The ratio is about 6%.

[0038] Step 3: Use a mechanical pump to evacuate to below 3Pa, and then use a molecular pump to evacuate to 10 -4 Below Pa, and h...

Embodiment 2

[0045] Step 1: Same as Step 1 of Example 1.

[0046] Step 2: Using a silicon-ruthenium composite target with a diameter of 100mm and a thickness of 3mm, four pure ruthenium blocks with a size of 4mm×15mm×1mm are symmetrically embedded on the sputtering track of the silicon target. The ratio of the ruthenium bulk to the sputtering track area of the silicon target is about 4%.

[0047] Step 3: Same as Step 3 of Example 1.

[0048] Step 4: Same as Step 4 of Example 1.

[0049] Step 5: Same as Step 5 of Example 1.

[0050] The measured thickness d of the obtained silicon-ruthenium alloy film was 864 nm, the length L was 4 mm, and the width W was 7 mm. The test results at room temperature are shown in Table 2, in which the conductivity and TCR of the intrinsic amorphous silicon film are obtained from reference materials, and the film square resistance is calculated at the same thickness d.

[0051] Table 2

[0052] Amorphous silicon based thin film Film conductiv...

Embodiment 3

[0054] Step 1: Same as Step 1 of Example 1.

[0055] Step 2: Using a silicon-ruthenium composite target with a diameter of 100mm and a thickness of 3mm, two pure ruthenium blocks with a size of 4mm×15mm×1mm are symmetrically embedded on the sputtering track of the silicon target. The ratio of the ruthenium bulk to the sputtering track area of the silicon target is about 2%.

[0056] Step 3: Same as Step 3 of Example 1.

[0057] Step 4: Same as Step 4 of Example 1.

[0058] Step 5: Same as Step 5 of Example 1.

[0059] The measured thickness d of the obtained silicon-ruthenium alloy film was 770 nm, the length L was 4 mm, and the width W was 7 mm. The test results at room temperature are shown in Table 3, in which the conductivity and TCR of the intrinsic amorphous silicon film are obtained from reference materials, and the square resistance is obtained by calculation at the same thickness d.

[0060] table 3

[0061] Amorphous silicon based thin film Film co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com