Composition containing branched polymer for vibration-damping material

A damping material and polymer technology, which is used in springs made of plastic materials, other chemical processes, mechanical equipment, etc., can solve the problems of low elastic modulus, limited polymer filler content, and poor viscosity, and achieve high damping. (Energy attenuation), high degree of freedom in material design, and improved physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0327] The method for preparing the damping material of the present invention is not particularly limited, and may be prepared in the form of a one-component type that cures with moisture in the air after all the compounding components are mixed in advance, sealed and stored, or It is prepared as a 2-component type in which components such as a curing catalyst, filler, plasticizer, and water are previously blended as a curing agent, and the blended materials and polymer composition are mixed before use. If it is a 2-component type, a colorant can be added when mixing the 2 components. If the colorant is a material obtained by mixing and slurrying a filler such as a pigment, a plasticizer, and depending on the case, handling is easy. In addition, by adding a retarder when mixing the two components, the curing speed can be fine-tuned at the job site.

[0328] "Damping Material"

[0329] A damping material obtained by curing the composition for a damping material containing the ...

Embodiment

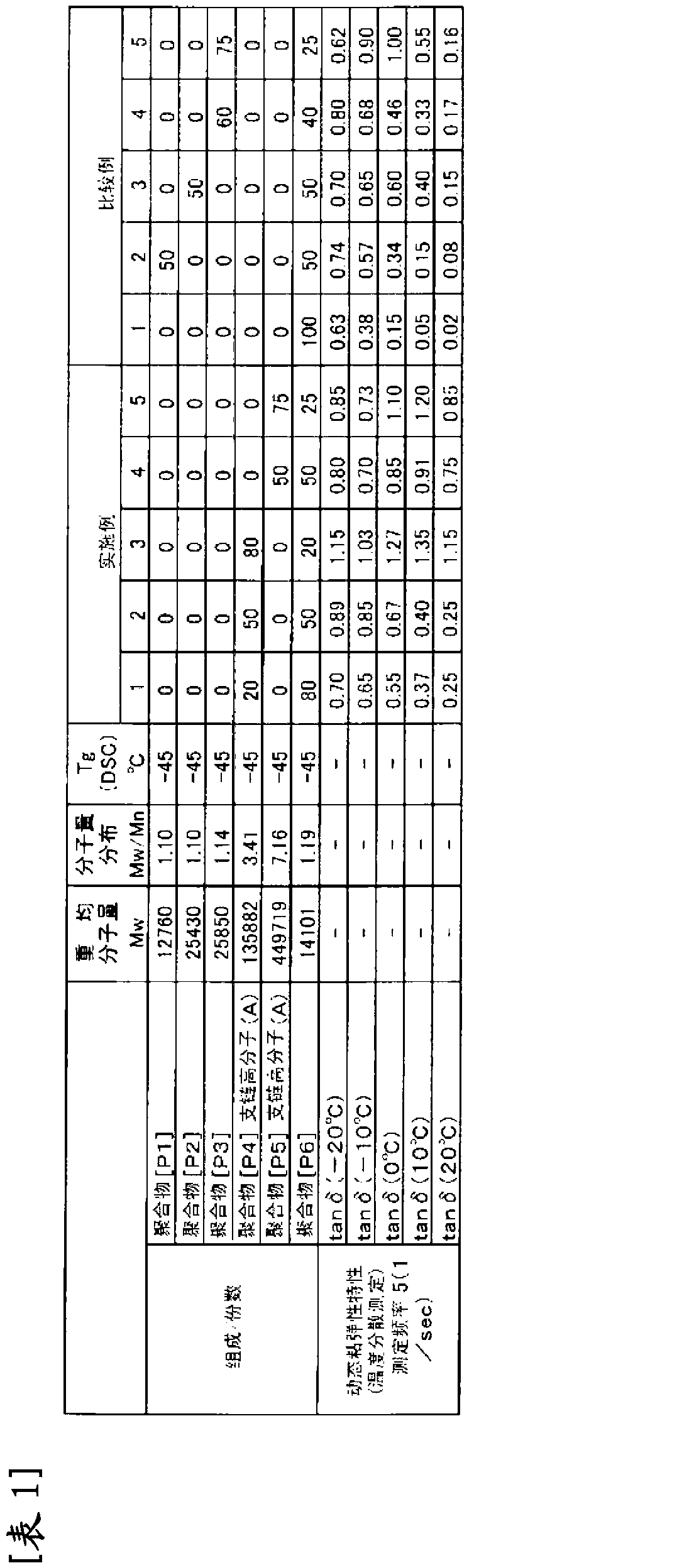

[0335] Hereinafter, specific examples and comparative examples of the present invention will be described together, but the present invention is not limited to the following examples.

[0336] "Parts" and "%" in the following Examples and Comparative Examples represent "parts by weight" and "% by weight", respectively. In addition, the term "triamine" in this example refers to pentamethyldiethylenetriamine.

[0337] In the following examples, "weight average molecular weight" and "molecular weight distribution (ratio of weight average molecular weight to number average molecular weight)" were calculated by the standard polystyrene conversion method using gel permeation chromatography (GPC). Among them, products filled with polystyrene cross-linked gel (shodex GPCK-804, K-802.5; manufactured by Showa Denko) were used as the GPC column, and chloroform was used as the GPC solvent. In addition, the number of functional groups introduced per 1 molecule of polymer can be used 1 Th...

manufacture example 1

[0339] (Synthesis of poly(n-butyl acrylate) having an acryloyl group at one end)

[0340] (1) Polymerization process

[0341] 100 parts of n-butyl acrylate are deoxygenated. The interior of a stainless steel reaction vessel with a stirrer was deoxidized, 0.42 parts of cuprous bromide and 20 parts of deoxidized n-butyl acrylate were charged, and heated and stirred. Add 4.4 parts of acetonitrile and 1.9 parts of ethyl α-bromobutyrate as an initiator, mix them, and add 0.018 parts of pentamethyldiethylenetriamine (hereinafter referred to as triamine) to initiate polymerization. Add the remaining 80 parts of n-butyl acrylate sequentially to promote the polymerization reaction. During the polymerization, it is appropriate to add triamine to adjust the polymerization speed. The total amount of triamines used in the polymerization was 0.06 parts. When the polymerization progresses, the internal temperature rises due to the heat of polymerization, so the polymerization is carried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com