Method for combined processing of phosphogypsum and phosphate reverse flotation tailings

A combined processing and reverse flotation technology, applied in the field of flotation, can solve problems such as restricting the promotion of projects, and achieve the effect of increasing enterprise resource reserves, high rationality, and alleviating environmental protection and resource difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

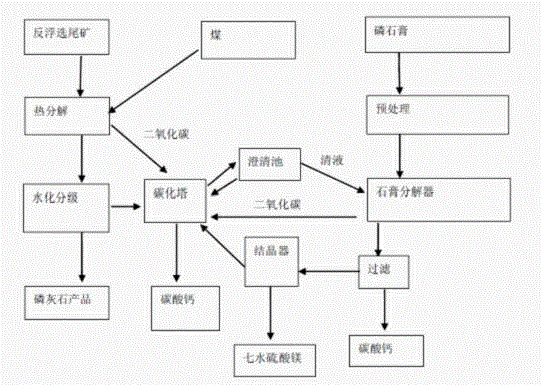

Image

Examples

Embodiment 1

[0021] First, thermally decompose the phosphate rock reverse flotation tailings at 750°C until the decomposition rate of dolomite contained in the phosphorus rock reverse flotation tailings is 80%, collect the carbon dioxide in the gas phase, and then hydrate the obtained powder to powder The hydration rate of magnesium oxide in the material is 70%, and then the hydrated slurry is classified. The material with a large specific gravity is a phosphorus mineral raw material, and the material with a small specific gravity is collected in a carbonization tower at 65 ° C. Carry out carbonization in the material until the extraction rate of magnesium hydroxide in the material is 50%, then clarification, solid-liquid separation, the solid material is calcium carbonate, the liquid material is heavy magnesium water, and the phosphogypsum is pretreated and added to heavy magnesium water for metathesis reaction , the molar ratio of sulfate radicals in phosphogypsum to magnesium ions in hea...

Embodiment 2

[0025] First, thermally decompose the phosphate rock reverse flotation tailings at 950°C until the decomposition rate of dolomite contained in the phosphate rock reverse flotation tailings is 99%, collect carbon dioxide in the gas phase, and then hydrate the obtained powder to powder The hydration rate of magnesium oxide in the material is 99%, and then the hydrated slurry is classified, and the material with a large specific gravity is a phosphorus mineral raw material, and the material with a small specific gravity is collected in a carbonization tower at 10 ° C. Carry out carbonization in the material until the extraction rate of magnesium hydroxide in the material is 99%, then clarification, solid-liquid separation, the solid material is calcium carbonate, the liquid material is heavy magnesium water, and the phosphogypsum is pretreated and added to the heavy magnesium water for metathesis reaction , the molar ratio of sulfate radicals in phosphogypsum to magnesium ions in ...

Embodiment 3

[0029] First, thermally decompose the phosphate rock reverse flotation tailings at 850°C until the decomposition rate of dolomite contained in the phosphorus rock reverse flotation tailings is 80%, collect the carbon dioxide in the gas phase, and then hydrate the obtained powder to powder The hydration rate of magnesium oxide in the material is 70%, and then the hydrated slurry is classified, and the material with a large specific gravity is a phosphorus mineral raw material, and the material with a small specific gravity is collected in a carbonization tower at 55 ° C. Carry out carbonization in the material until the extraction rate of magnesium hydroxide in the material is 50%, then clarification, solid-liquid separation, the solid material is calcium carbonate, the liquid material is heavy magnesium water, and the phosphogypsum is pretreated and added to heavy magnesium water for metathesis reaction , the molar ratio of sulfate radicals in phosphogypsum to magnesium ions in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com