Electrodynamic force-reinforced leaching in-situ restoration apparatus for persistent organic contaminated soil

An organic pollution and persistent technology, applied in the restoration of polluted soil, etc., can solve the problems of soil organic matter and soil water damage, large energy consumption, etc., and achieve the effect of promoting hydrolysis and migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

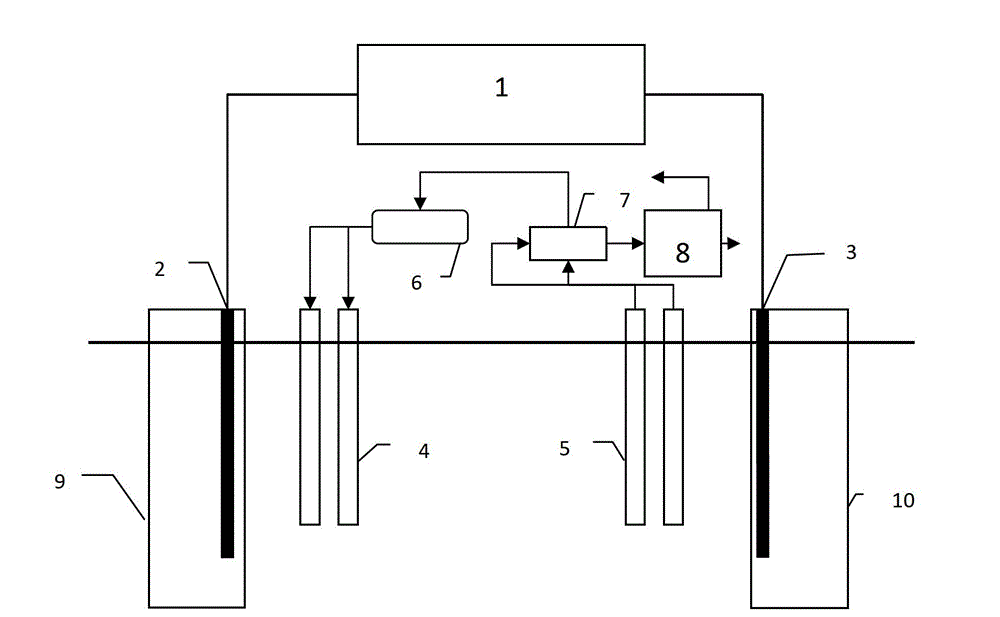

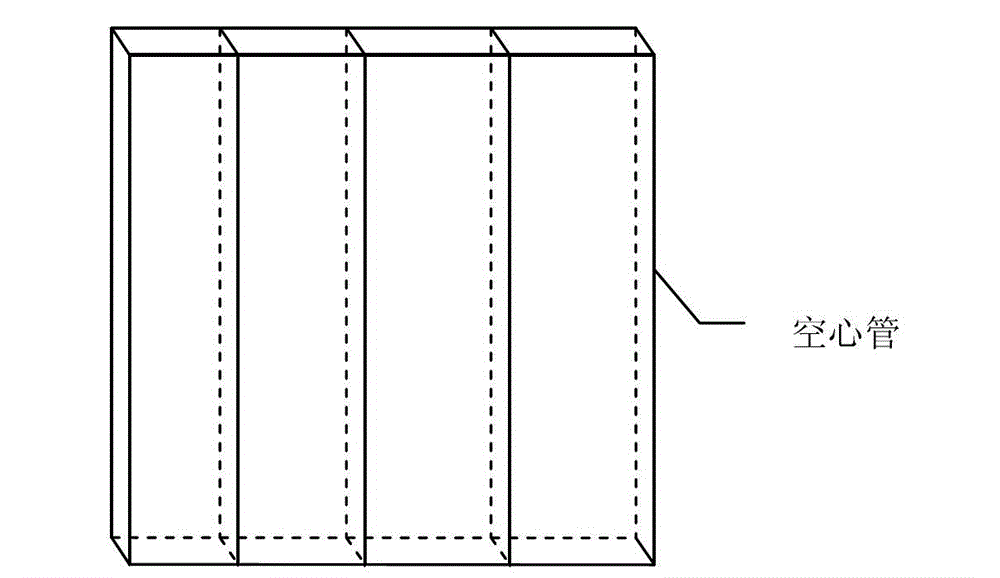

[0032]First, insert the electrode anode 2 and the electrode cathode 3 at the two ends of the polluted soil respectively, and at the same time inject a sodium acetate solution with a concentration of 0.05~0.1 mol / L into the electrode anode 2 as the anode buffer solution, and the electrode cathode 3 with a concentration of 0.01~0.05 mol / L potassium nitrate solution as the cathode buffer solution. The electrodes and repair materials were introduced into a specially designed hollow tube, which was 51 cm wide, 5 cm thick, and 17-18 m long; the hollow tube was welded by four hollow tubes with a width of 12.7 cm and a wall thickness of 5 cm. The hollow pipe is mounted on an 18-meter-high tower mast. It is moved and rammed into the ground by a crane and a vibratory pile driver. The hollow pipe is 14 meters into the ground and 3 meters are exposed on the ground. The electrode is composed of iron filings and Loresco coke, and the electrode is about 13.7~14.0 m into the ground. A DC vo...

Embodiment 2

[0036] A certain range of PAHs-contaminated soil was selected around the fertilizer plant for treatment. The structure of the restoration device used was the same as in Example 1. There were 4-5 injection wells at the anode of the electrode, and 4-5 extraction wells at the cathode of the electrode. An aqueous n-butylamine solution with a volume concentration of 15% to 25% was used as the eluent, and NaOH with a concentration of 0.01 mol / L was used as the anode buffer to maintain the alkaline conditions of the anode. Apply a periodic voltage with a voltage gradient of 2 VDC / cm for five days, and then use a chemical solution of n-butylamine with a volume concentration of 15% to 25% as the eluent to wash the soil for 4 to 6 hours. This cycle is repeated for about 1000 hours. In the initial stage, nickel ions move to the electrode cathode 3 under the action of electromigration. However, with the pH and eluent washing, nickel will gradually precipitate and no longer migrate to the e...

Embodiment 3

[0038] A certain range of contaminated soil was selected in the lead-contaminated soil site for processing, and the structure of the processing device adopted was the same as in Example 1. The soil near the electrode anode 2 was inserted into the injection well 4, and the soil near the electrode cathode 3 was inserted into the extraction well 5. The contaminated soil with a lead content of 440 mg / kg was treated. The voltage gradient is 1.5 V / cm, and the EDTA aqueous solution with a concentration of 0.1-0.3 mol / L is selected as the chemical leaching reagent. The electromotive force action time is about 300 hours, and the lead removal rate can reach about 70% after the test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com