Plant water conservation and usage system in semiconductor industry

A semiconductor and industry technology, applied in the field of pure water treatment, grinding wastewater treatment and water saving management mathematical model, it can solve the problems of increasing sludge volume, affecting water quality purity, limited future of water quality utilization, etc., to improve recycling rate, The effect of improving the quality of silicon powder recycling and avoiding chemical pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

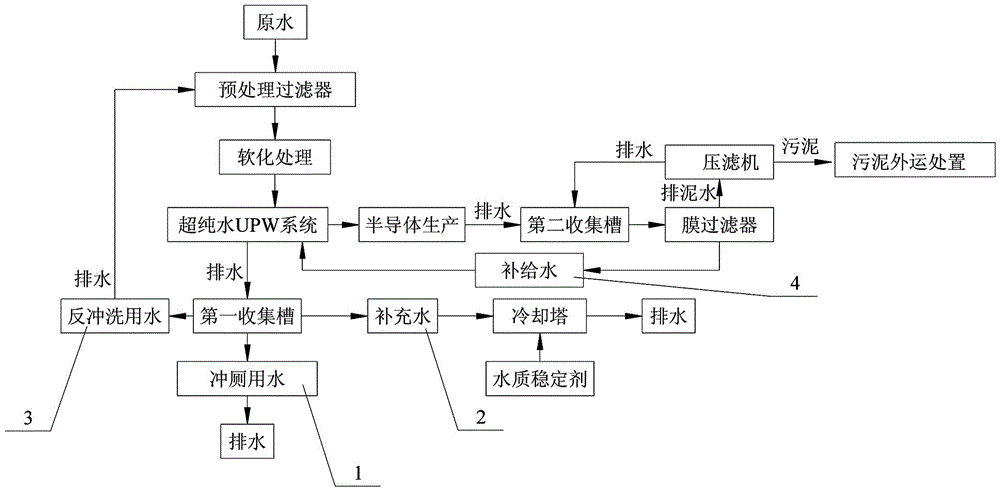

[0022] The ultrapure water UPW system of an electronics factory in Shanghai has a processing capacity of 100m 3 / h, its displacement is 44m 3 / h. After the drainage is collected to the first collection tank, all the way is used as water for toilet flushing in the living area of the factory (6~9m 3 / h) discharge, all the way through the treatment of water quality stabilizer as the water replenishment of the cooling tower system of the factory (30m 3 / h), the other is used as the backwash water of the water supply pretreatment equipment in the ultrapure water UPW system (88~117m 3 / d), the water after the backwashing of the water supply pretreatment equipment is softened with an ion exchanger and then re-enters the ultrapure water system. In this way, the water used in the semiconductor production process is used twice, which saves the consumption of municipal tap water in the above three parts and saves resources.

[0023] UPW ultrapure water is mainly used for the produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com