N-ethyl aniline preparation method

A technology of aniline and acetaldehyde, which is applied in the field of preparation of N-ethylaniline, can solve the problems of unfavorable production of N-ethylaniline, poor yield and purity, relatively high equipment requirements, and achieve easy separation, high purity, The effect of advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

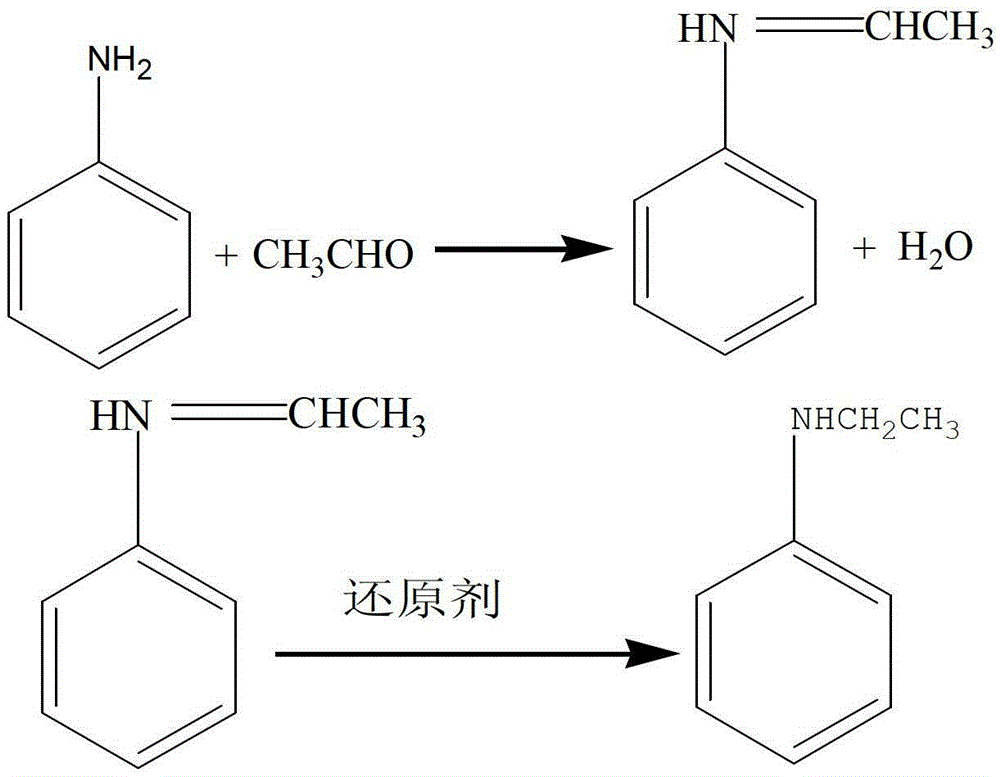

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of N-ethylaniline, its concrete steps are:

[0032] (1) Nucleophilic reaction

[0033] At normal temperature and pressure, add 18.26g of aniline into the reactor, stir, then add the ethanol solution of acetaldehyde (20.62g of acetaldehyde, the mass ratio of acetaldehyde to ethanol is 1:2), and react for 1 hour;

[0034] (2) Reduction reaction

[0035] At normal temperature and pressure, add an ethanol solution of sodium borohydride (wherein the mass ratio of reducing agent sodium borohydride is 11.42 g, and the mass ratio of reducing agent to ethanol is 1:6) to the above reaction system, and react for 3 hours;

[0036] (3) Post-processing

[0037] The reactant after the above reduction reaction was distilled to obtain an organic phase, the organic phase was alkalized, and then distilled to obtain an organic phase, the organic phase was acidified, and then distilled, the organic phase was 23.33g of the product, with a yield of 96.2% and a c...

Embodiment 2

[0040] A kind of preparation method of N-ethylaniline, its concrete steps are:

[0041] (1) Nucleophilic reaction

[0042] At normal temperature and pressure, add 18.22g of aniline into the reactor, stir, then add the ethanol solution of acetaldehyde (20.64g of acetaldehyde, the mass ratio of acetaldehyde to ethanol is 1:5), and react for 1 hour;

[0043] (2) Reduction reaction

[0044] At normal temperature and pressure, add an ethanol solution of sodium borohydride (wherein the mass ratio of reducing agent sodium borohydride is 11.44 g, and the mass ratio of reducing agent to ethanol is 1:5) to the above reaction system, and react for 3 hours;

[0045] (3) Post-processing

[0046]The reactant after the above reduction reaction was distilled to obtain an organic phase, the organic phase was alkalized, and then distilled to obtain an organic phase, the organic phase was acidified, and then distilled, the organic phase was 23.35 g of the product, with a yield of 96.5% and a c...

Embodiment 3

[0049] A kind of preparation method of N-ethylaniline, its concrete steps are:

[0050] (1) Nucleophilic reaction

[0051] At normal temperature and pressure, add 18.26g of aniline into the reactor, stir, then add acetaldehyde in methanol solution (among them, the acetaldehyde is 20.62g, and the mass ratio of acetaldehyde to methanol is 1:4), and react for 1 hour;

[0052] (2) Reduction reaction

[0053] At normal temperature and pressure, add a methanol solution of sodium borohydride (wherein the mass ratio of reducing agent sodium borohydride is 11.43 g, and the mass ratio of reducing agent to methanol is 1:10) to the above reaction system, and react for 3 hours;

[0054] (3) Post-processing

[0055] The reactant after the above reduction reaction was distilled to obtain an organic phase, the organic phase was alkalized, and then distilled to obtain an organic phase, the organic phase was acidified, and then distilled, the organic phase was 23.43g of the product, with a yi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com