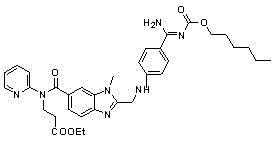

Preparation method of 3-(2-pyridine amino) ethyl propionate

A kind of technology of ethyl propionate and pyridyl amino, applied in the field of preparation of ethyl 3-propionate, can solve problems such as long synthesis steps, high production cost, complicated operation, etc., achieves short synthesis steps, low production cost and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

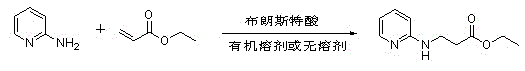

[0028] A kind of preparation method of 3-(2-pyridine amino) propionate ethyl ester, promptly take 2-aminopyridine and ethyl acrylate as raw material, under the condition of solvent-free, take p-toluenesulfonic acid as catalyst, control temperature is 100 Reaction at ℃ for 24h, the reaction to obtain ethyl 3-(2-pyridylamino)propionate, the specific steps are as follows:

[0029] Add 2-aminopyridine (0.47g, 5mmol) and ethyl acrylate (1.0g, 10mmol) in a 25mL round bottom flask or a 15mL sealed tube, and add p-toluenesulfonic acid (0.5mmol, 10mol%) ) as a catalyst, and the temperature was controlled to react at 100°C for 24h. The resulting reaction solution is concentrated under reduced pressure at a temperature of 40-45°C and a pressure of 0.09-0.1 MPa, and the concentrated solution is passed through a silica gel column or an aluminum oxide column with a ratio of petroleum ether:ethyl acetate of 8:1 to 5 After the eluent at 1:1 was subjected to column chromatography, the eluent ...

Embodiment 2

[0034] A preparation method of ethyl 3-(2-pyridineamino) propionate, which is to use 2-aminopyridine and ethyl acrylate as raw materials, under solvent-free conditions, use nitric acid as a catalyst, and react at a controlled temperature of 100°C 24h obtains 3-(2-pyridylamino) ethyl propionate, and concrete steps are as follows:

[0035] Add 2-aminopyridine (0.47g, 5mmol) and ethyl acrylate (1.0g, 10mmol) into a 25mL round-bottom flask or a 15mL sealed tube, and use nitric acid (0.5mmol, 10mol%) as a catalyst under solvent-free conditions, React at 100°C for 24h. The resulting reaction solution is concentrated under reduced pressure at a temperature of 40-45°C and a pressure of 0.09-0.1 MPa, and the concentrated solution is passed through a silica gel column or an aluminum oxide column with a ratio of petroleum ether:ethyl acetate of 8:1 to 5 After the eluent of 1:1 was subjected to column chromatography, the eluent of 5:1 was collected, and the white solid obtained by spinni...

Embodiment 3

[0037] A kind of preparation method of 3-(2-pyridineamino) propionate ethyl ester, promptly take 2-aminopyridine and ethyl acrylate as raw material, under the condition of solvent in ethanol, take p-toluenesulfonic acid as catalyzer, control temperature is Reaction at 100°C for 24h to obtain ethyl 3-(2-pyridylamino)propionate, the specific steps are as follows:

[0038]2-Aminopyridine (0.47g, 5mmol) and ethyl acrylate (1.0g, 10mmol) were added to a 25mL round-bottomed flask or a 15mL sealed tube, and under the condition of ethanol (1mL) as a solvent, p-toluenesulfonic acid ( 0.5mmol, 10mol%) as the catalyst, the reaction temperature is controlled at 100°C for 24 hours respectively, and the obtained reaction liquid is concentrated under reduced pressure at a temperature of 40-45°C and a pressure of 0.09-0.1MPa, and the concentrated liquid is passed through a silica gel column Or aluminum oxide column is equipped with petroleum ether: the eluent of ethyl acetate ratio is 8:1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com