Chemical imidization accelerant of polyamide acid and polyimide thin film manufacturing method

A technology of polyimide chemical imide and polyamic acid glue, applied to polyimide film, chemical imidization of polyimide film, catalyst and dehydration for chemical imidization of polyamic acid In the field of pharmaceuticals, it can solve the problems of low production efficiency, poor performance of finished products, and lack of market competitiveness, and achieve the effects of good dimensional stability, low linear expansion coefficient, and small residual internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

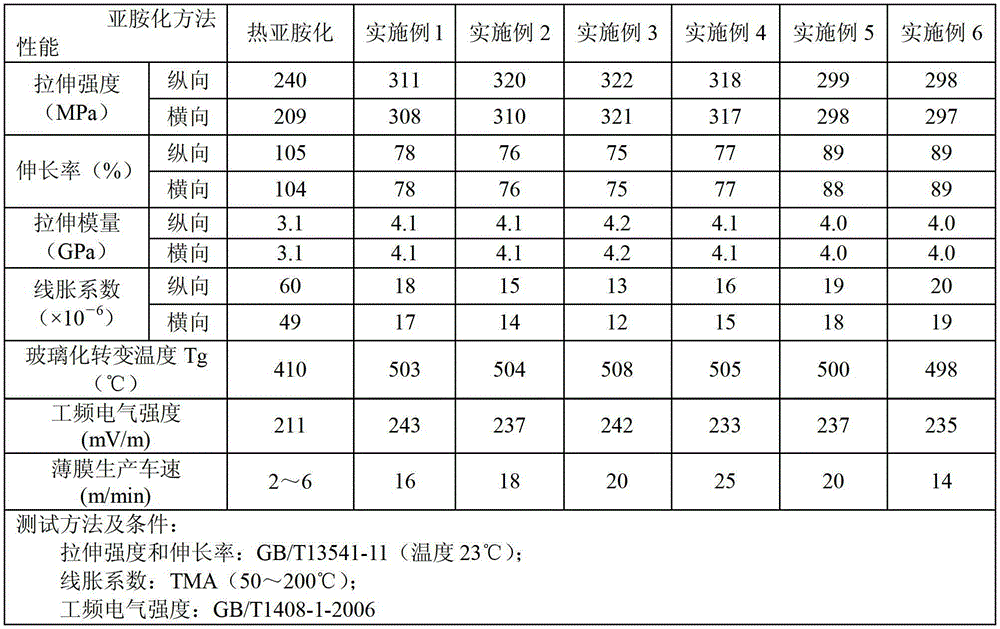

Examples

Embodiment 1

[0037] Add 200kg of N,N-dimethylformamide, 45kg of N,N-dicyclohexylcarbodiimide, 41kg of benzoic anhydride, 10kg of quinoline and diisopropyl Ethylamine 65kg, after stirring and mixing evenly, mix it with the polyamic acid solution with a solid content of 20% and a viscosity of 245,100 centipoise at a mass ratio of 1:6, filter and vacuum degassing, and then extrude The die device drool is coated on the endless stainless steel belt with a folded diameter of 6-15m in a closed clean system, and the chemical imidization is carried out in three stages at 75°C, 130°C, and 175°C at a speed of 16m / min, and then The partially chemically imidized gel film with a solid content of 28-32% is peeled off the endless steel strip through the peeling roller, and sent in with a rubber roller, or sent to 300°C, 400℃, 450℃, 475℃ and 250℃ high-temperature furnaces with five temperature sections for complete imidization treatment, so that the residual solvent content in the film is 2.8% to 3%, and f...

Embodiment 2

[0039] Add 180kg of N,N-dimethylformamide, 100kg of acetic anhydride, 35kg of benzoic anhydride, 60kg of isoquinoline, 1,8-di(N,N-dimethyl Amino)naphthalene 16kg, after stirring and mixing evenly, mix it with polyamic acid solution with a solid content of 18.5% and a viscosity of 236,600 centipoise at a mass ratio of 1:7, filter, vacuum debubble, and squeeze The die head device drool is coated on the endless stainless steel belt with a folded diameter of 6-15m in a closed clean system, and the chemical imidization is carried out in three stages at 65°C, 125°C, and 165°C at a speed of 18m / min. Then the partially chemically imidized gel film with a solid content of 28 to 35% is peeled off the endless steel strip through the peeling roller, and sent in with a rubber roller, or sent to 300°C after being biaxially stretched with a stretch ratio of 1.2. , 400°C, 450°C, 475°C and 250°C five-temperature high-temperature furnace for complete imidization treatment, so that the residual ...

Embodiment 3

[0041] Add 200kg of N,N-dimethylformamide, 30kg of acetic anhydride, 21kg of benzoic anhydride, 45kg of N,N-dicyclohexylcarbodiimide, and 15kg of isoquinoline into a storage tank at a temperature of -10±2°C , 10kg of quinoline and 45kg of diisopropylethylamine were stirred and mixed evenly, and mixed with a polyamic acid solution having a viscosity of 241,900 centipoise with a solid content of 19.1% in a mass ratio of 1:5, filtered, After vacuum defoaming, it is drool-coated on an endless stainless steel belt with a diameter of 6-15m in a closed clean system through the extrusion die device, at a speed of 20m / min, at 75°C, 130°C, and 175°C for three times. Sectional chemical imidization, and then the partially chemically imidized gel film with a solid content of 28-35% is peeled off the endless steel strip through the peeling roller, and is sent in with a rubber roller, or through a two-way stretching ratio of 1.2 After stretching, it is sent to a high-temperature furnace with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com