Emulsion type acrylic ester adhesive for anti-yellowing polishing membrane and preparation method thereof

A polyacrylate, emulsion-type technology, applied in the direction of ester copolymer adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problem of affecting consumers' purchase desire, easy yellowing, poor water resistance, etc. problems, to achieve the effects of good performance, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The examples given below specifically illustrate the present invention, but the present invention is not limited to these examples. The percentages in the following examples (unless otherwise specified) are all percentages by weight.

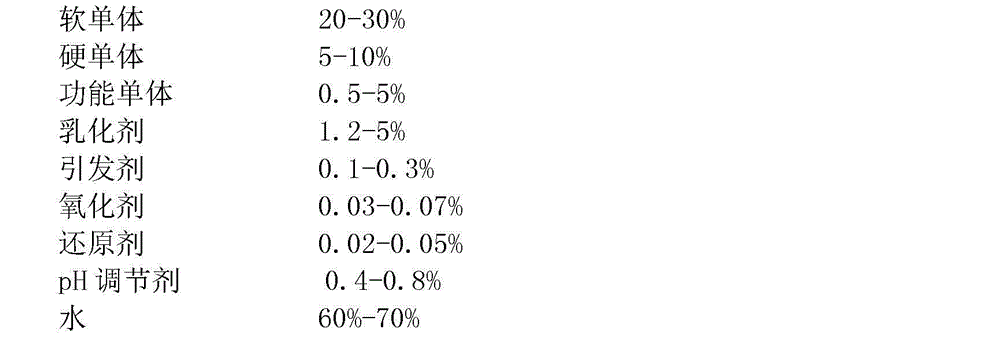

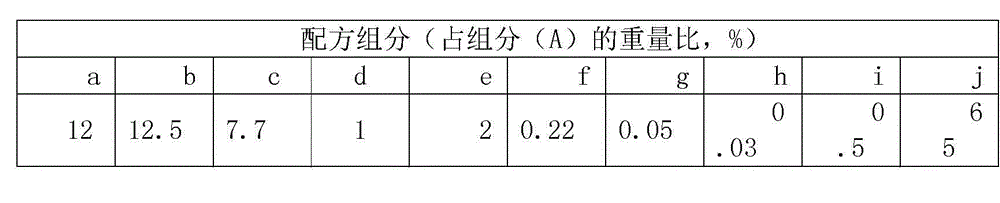

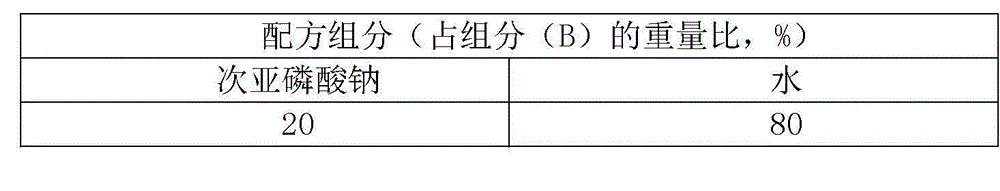

[0025] According to the formula in Table 1, component (A) is formed by emulsion polymerization. According to the formula in Table 2, component (B) is a mixture of water and strong reducing agent sodium hypophosphite at room temperature. According to the formula in Table 3, slowly add component (B) to component (A) and stir and mix uniformly at room temperature to obtain an emulsion type polyacrylate pressure-sensitive adhesive. The adhesive is now available and has the best performance.

[0026] Use the RK wire rod coater to coat the pressure-sensitive adhesive on the 19 μm BOPP film. The thickness of the adhesive layer is about 15 μm. The temperature is raised to 100°C. After drying, the thickness of the adhesive layer is about 7 μm. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com