Environment-friendly tackifier for oil-based drilling fluid and preparation method thereof

A technology of oil-based drilling fluid and viscosifier, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve the problems of environmental protection of oil-based drilling fluid, increase of organic soil, and filter reduction of oil-based drilling fluid Problems such as the addition of materials such as loss agent polymers and the increase in the cost of oil-based drilling fluid preparation have achieved good effects of increasing viscosity and cutting, reducing preparation costs, and improving environmental performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

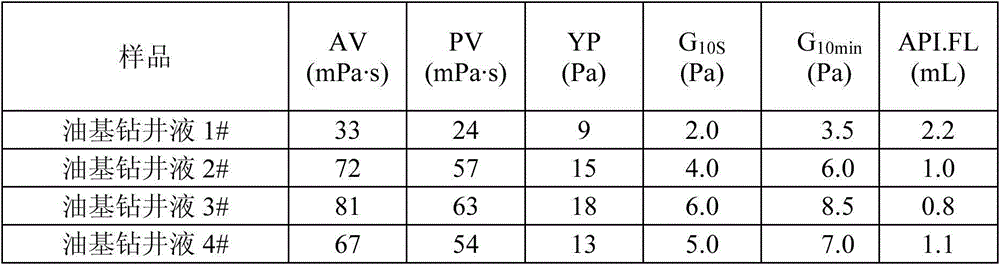

Examples

Embodiment 1

[0028] This embodiment provides an environment-friendly oil-based drilling fluid viscosifier, the preparation method of which comprises the following steps:

[0029] Under stirring conditions, add 3.0g of N,N'-methylenebisacrylamide into 30mL of water and fully dissolve; add 6.0g of 2-acrylamido-2-methylpropanesulfonic acid and continue stirring to fully dissolve After adding 0.2g polyvinylpyrrolidone, continue to stir to make it fully dissolved; add 0.05g potassium persulfate, continue to stir to make it fully dissolve, and form an aqueous phase solution;

[0030] Under stirring conditions, dissolve 1.25g of Span 80 in 2.0mL of simethicone oil to form an oil phase solution;

[0031] Under stirring conditions, slowly drop the water phase solution into the oil phase solution through a separatory funnel, then add 0.05 g of ferrous sulfate, and stir evenly to form a mixed solution;

[0032] The mixed solution was polymerized for 4 hours in a water bath at 50°C under stirring con...

Embodiment 2

[0035] This embodiment provides an environment-friendly oil-based drilling fluid viscosifier, the preparation method of which comprises the following steps:

[0036] Under stirring conditions, add 6.0g of methacrylamide into 40mL of water and fully dissolve it; add 12.0g of 3-morpholine propanesulfonic acid and continue to stir to fully dissolve it; add 0.8g of N-vinylpyrrolidone and continue to stir After making it fully dissolved; add 0.15g ammonium persulfate, continue stirring to make it fully dissolved, and form an aqueous phase solution;

[0037] Under stirring conditions, dissolve 2.75g Tween 60 in 6.0mL white oil to form an oil phase solution;

[0038] Under the condition of stirring, slowly drop the water phase solution into the oil phase solution through a separatory funnel, then add 0.15 g of sodium sulfite, and stir evenly to form a mixed solution;

[0039] The mixed solution was polymerized for 6 hours in a water bath at 70°C under stirring conditions to obtain a...

Embodiment 3

[0042] This embodiment provides an environment-friendly oil-based drilling fluid viscosifier, the preparation method of which comprises the following steps:

[0043] Under stirring conditions, add 7.5g of N-hydroxyacrylamide into 50mL of water and fully dissolve; add 18.0g of 3-hydroxy-1-propanesulfonic acid and continue to stir to fully dissolve; add 1.5g of α-pyrrolidone and continue to stir Make it fully dissolved; add 0.25g of azobisisobutyronitrile, continue stirring to make it fully dissolved, and form an aqueous phase solution;

[0044] Under stirring conditions, dissolve 4.25g emulsifier TX-100 in 10.0mL corn oil to form an oil phase solution;

[0045] Under stirring conditions, slowly drop the aqueous phase solution into the oil phase solution through a separatory funnel, then add 0.25 g of sodium bisulfite, and stir evenly to form a mixed solution;

[0046] The mixed solution was polymerized for 8 hours in a water bath at 80°C under stirring conditions to obtain a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com