Preparation method for tin-doped mesoporous silica smoke suppressant

A technology of mesoporous silica and smoke suppressant, which is applied in the direction of fireproof coatings, etc., can solve the problem that there is no relevant literature report on the catalytic conversion of smoke and poisonous gas, and achieve the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

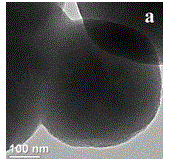

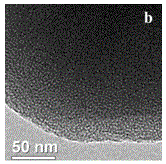

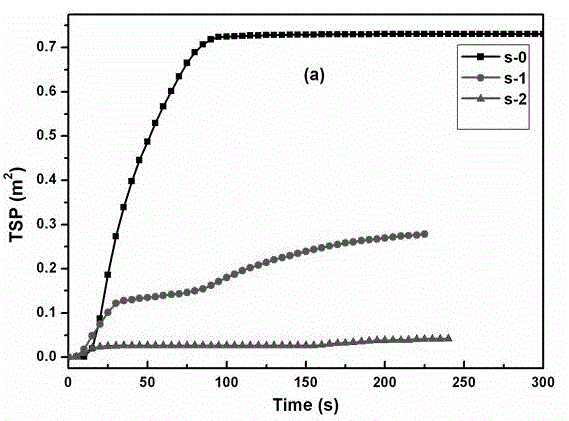

Image

Examples

Embodiment 1

[0026] At room temperature, dissolve 2g of cetyltrimethylammonium chloride in 960g of deionized water, add 6ml of 2mol / L NaOH solution, and stir evenly. Raise the temperature to 80°C, add 4g of SnCl with a mass percentage of 40% 4 ·5H 2 O aqueous solution, stirred for 15min, then added dropwise 10mL tetraethyl orthosilicate, stirred vigorously, and reacted at 80°C for 2h. The above-mentioned glue solution was transferred to a polytetrafluoroethylene-lined stainless steel hydrothermal kettle and sealed and matured at 105°C for 24 hours. After repeated washing and filtration, a white powder was obtained, and vacuum-dried. Then place it in a tube furnace and calcinate at a heating rate of 3°C / min to 550°C for 6h to obtain a tin-doped mesoporous silica smoke suppressant.

Embodiment 2

[0028] At room temperature, dissolve 1.96g of dodecyltrimethylammonium bromide in 800g of deionized water, add 12ml of 1mol / L NaOH solution, and stir evenly. Heat up to 70°C, add 8g of SnCl with a mass percentage of 40% 4 ·5H 2 The aqueous solution of O was stirred for 15 min, then 8.4 mL of methyl orthosilicate was added dropwise, stirred vigorously, and reacted at 70°C for 2 h. The above-mentioned glue solution was transferred to a polytetrafluoroethylene-lined stainless steel hydrothermal kettle and sealed and matured at 105°C for 24 hours. After repeated washing and filtration, a white powder was obtained, and vacuum-dried. Then place it in a tube furnace and calcinate at a heating rate of 3°C / min to 550°C for 6h to obtain a tin-doped mesoporous silica smoke suppressant.

Embodiment 3

[0030] At room temperature, dissolve 1.68g of tetradecyltrimethylammonium bromide in 748g of deionized water, add 5ml of 3mol / L NaOH solution, and stir evenly. Heat up to 80°C, add 2g of SnCl with a mass percentage of 40% 4 ·5H 2 O aqueous solution, stirred for 15min, then added dropwise 10mL tetraethyl orthosilicate, stirred vigorously, and reacted at 80°C for 2h. The above-mentioned glue solution was transferred to a polytetrafluoroethylene-lined stainless steel hydrothermal kettle and sealed and matured at 105°C for 24 hours. After repeated washing and filtration, a white powder was obtained, and vacuum-dried. Then place it in a tube furnace and calcinate at a heating rate of 3°C / min to 550°C for 6h to obtain a tin-doped mesoporous silica smoke suppressant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com