Hollow fiber zeolite membrane assembly and technology thereof

A molecular sieve and membrane module technology, applied in the field of inorganic membranes, can solve problems such as the sealing of hollow fiber molecular sieve membranes, achieve the effects of reducing processing costs, facilitating disassembly and replacement, and increasing the filling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

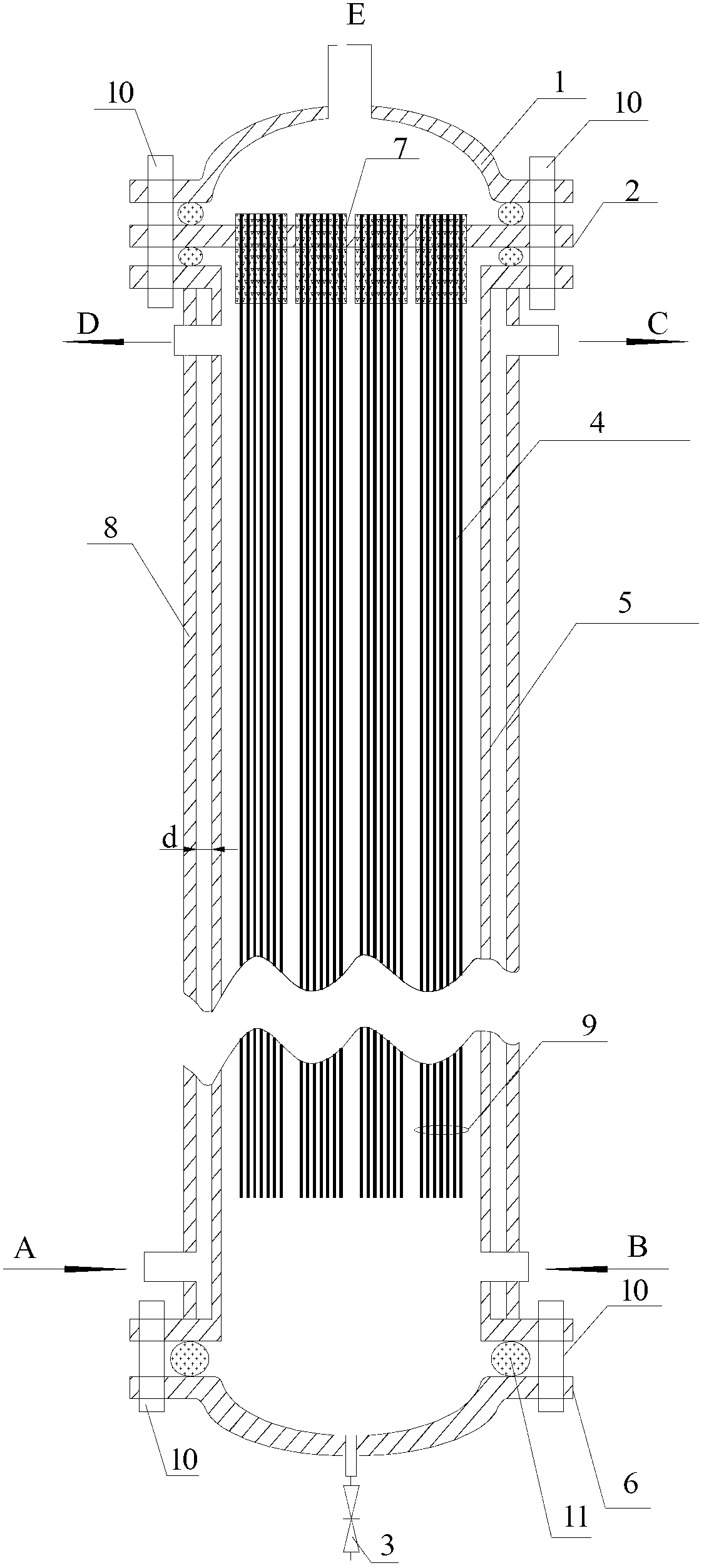

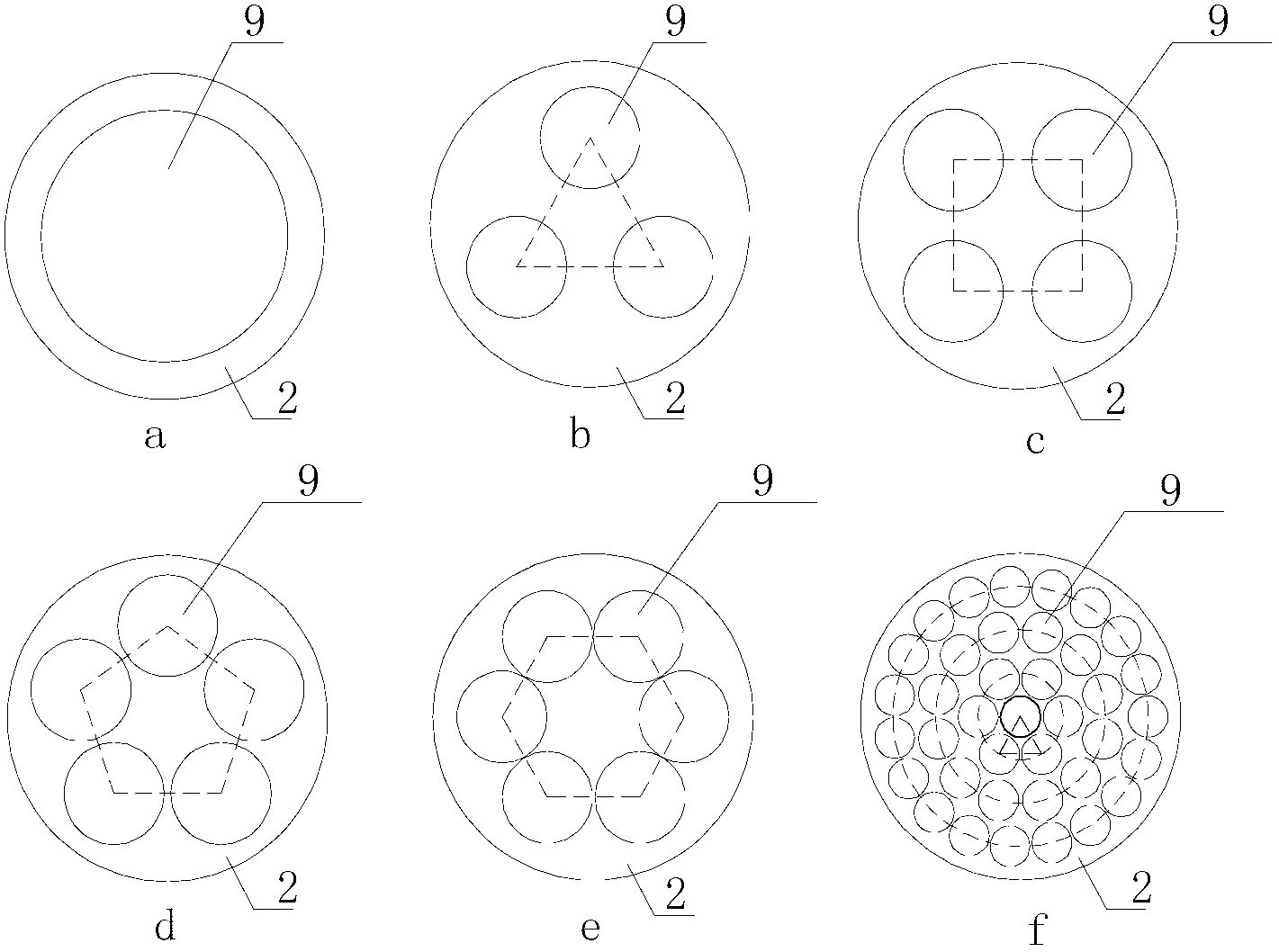

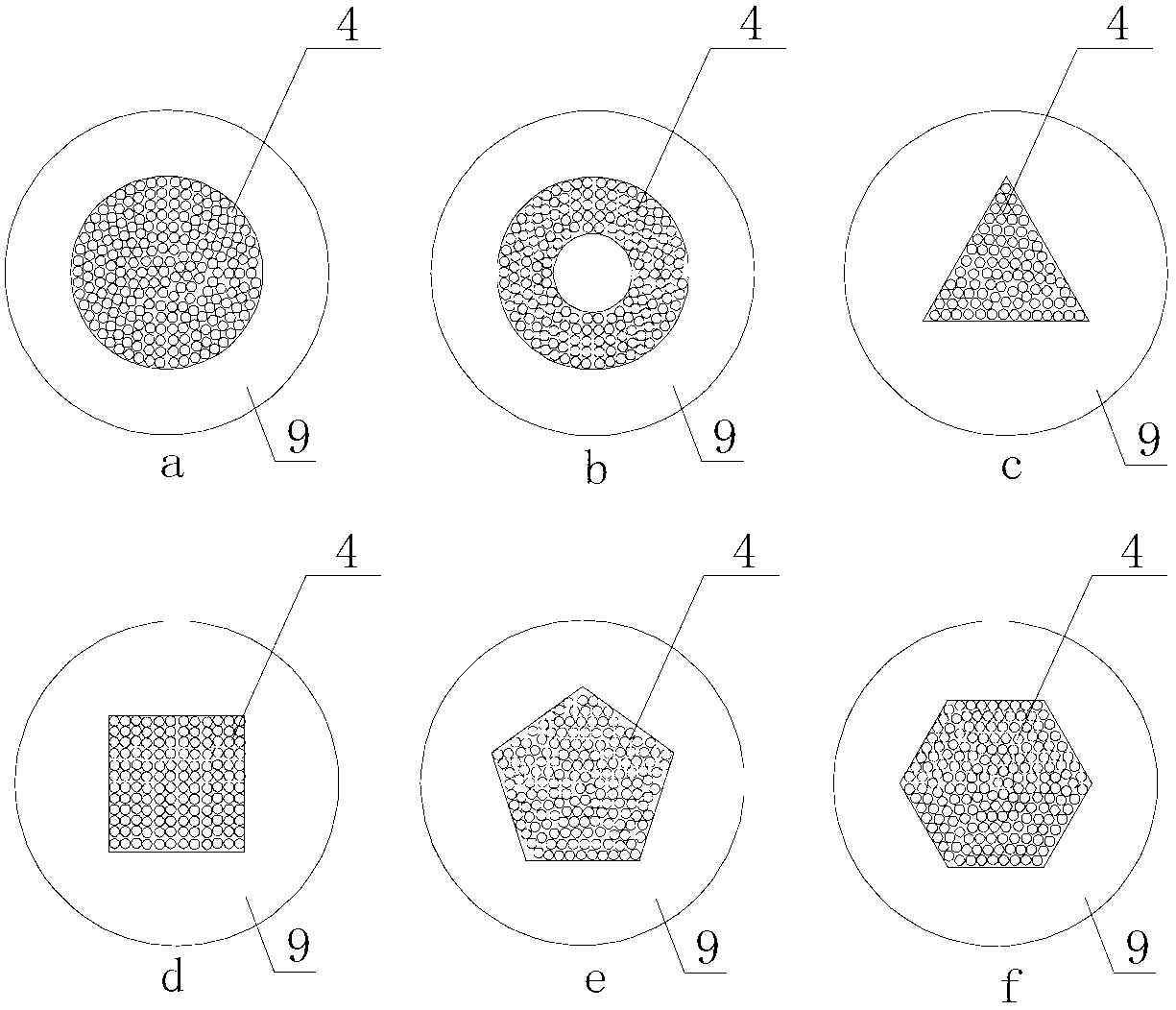

[0024] The schematic diagram of the axial section of the hollow fiber molecular sieve membrane module is as figure 1 Shown: It is composed of hollow fiber molecular sieve membrane element, orifice plate, shell, jacket, end and head: the shell has a jacket, and the hollow open end of the hollow fiber molecular sieve membrane element is fixed in the orifice plate and installed The orifice plate with membrane element is placed in the shell, the upper end of the shell, the orifice plate and the end are sealed by screw; the lower end of the shell and the head are sealed by the screw; the middle of the end is provided with a vacuum interface and the end The middle part is provided with a valve, the lower part of the jacket is provided with a heat exchange medium inlet, the lower part of the jacket is provided with a heat exchange medium outlet, the lower part of the shell is provided with an organic solvent inlet, and the upper part of the shell is provided with an organic solvent out...

Embodiment 2

[0029] According to the method of Example 1, 3000 hollow fiber NaA molecular sieve membranes with an outer diameter of 1.6mm and a length of 600mm were blocked with epoxy resin sealant at one end, arranged in a circle, and the hollow open end was filled with a ring Oxygen resin, let stand for 1 day, wait for the epoxy resin to solidify to complete the packaging of the hollow fiber molecular sieve membrane element; fix the membrane element to the stainless steel orifice plate with a clamp, and install the orifice plate in a stainless steel shell with a length of 750mm ( A hollow fiber molecular sieve membrane module with one membrane element (the membrane element contains 3000 hollow fiber molecular sieve membranes) is formed on the jacket gap d (180 mm). The membrane module is used for steam permeation dehydration of 90wt.% isopropanol / water system and shows good separation performance. When the feed temperature is 120°C and the feed pressure is 0.2MPa, the water content on the ...

Embodiment 3

[0031] According to the method of Example 1, 100 hollow fiber T-type molecular sieve membranes with an outer diameter of 1.8 mm and a length of 200 mm were encapsulated on a 7-hole orifice plate to form a hollow fiber molecular sieve membrane module with 7 membrane elements. The difference from Embodiment 2 is that the membrane element is fixed on the stainless steel orifice plate with silicone sealant, and the length of the stainless steel shell (the jacket gap d is 5 mm) is 250 mm. This module is used for the pervaporation dehydration of 90wt.% ethanol / water system, and the feed liquid circulation mode is adopted. When the feed temperature is 70°C and the feed pressure is 0MPa, the water content of the raw material can be reduced to less than 0.3wt.%, The relationship between the water content of the raw material and the operating time is as follows: Figure 5 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com