Synthesis method of ZnSe hollow microspheres by alcohol thermal reduction

A technology of micro-spheres and synthesis method, applied in the field of nanomaterials, can solve the problems of harsh equipment and process requirements, and achieve the effects of environmental friendliness, mild reduction performance and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

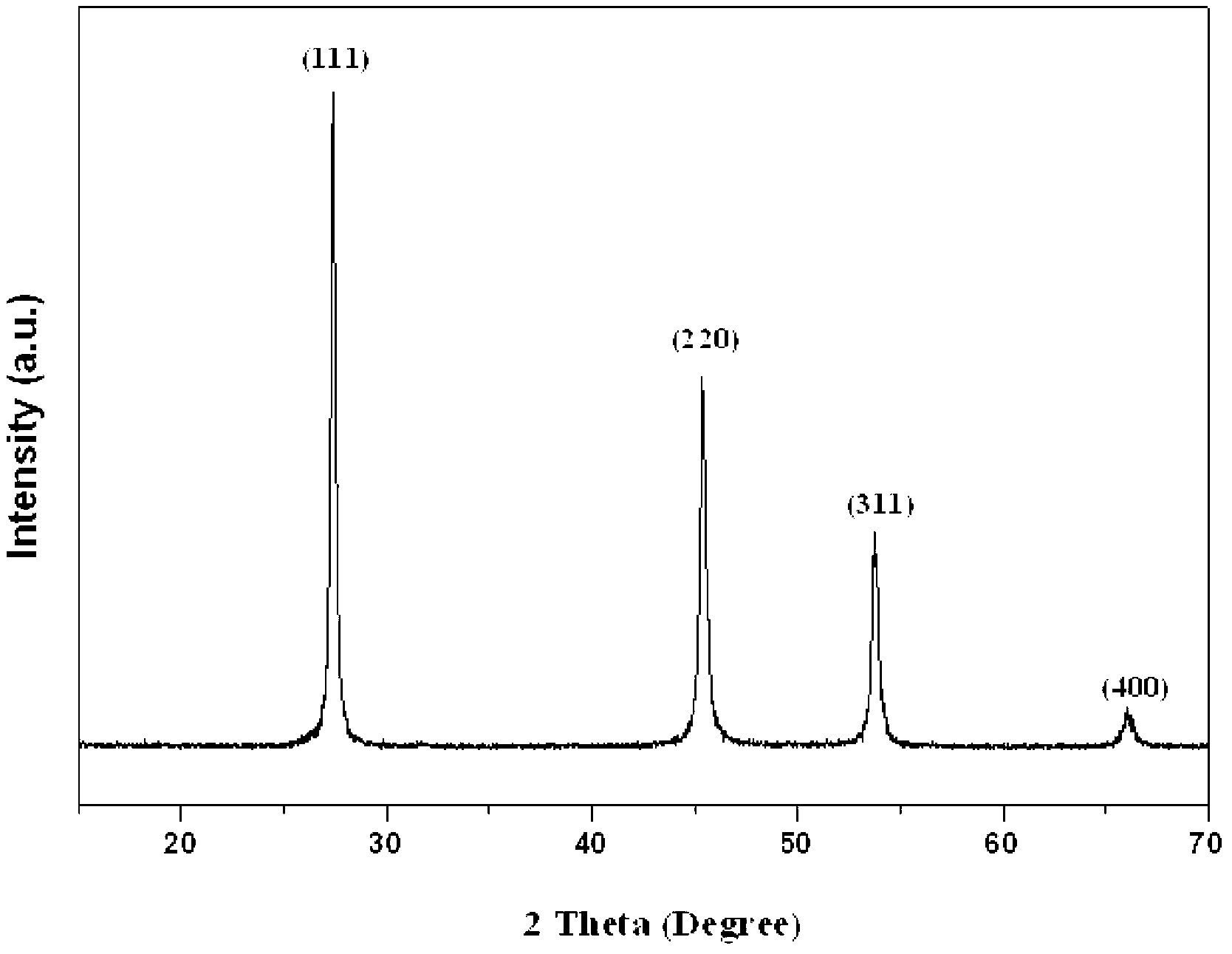

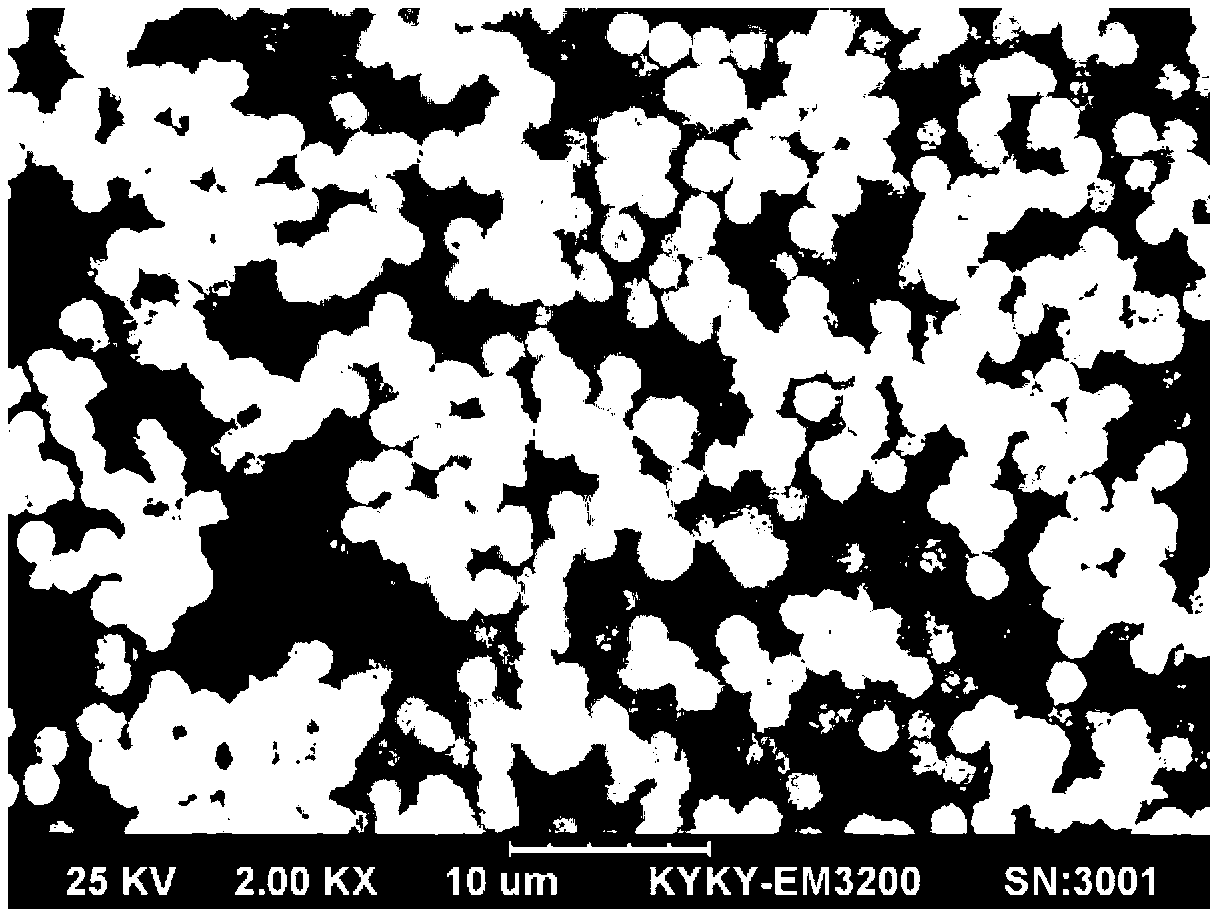

[0021] Prepare distilled water and ethylene glycol with a volume ratio of 1:3 to form a mixed solution, weigh 2.5mmol analytically pure sodium selenite, 2.5mmol zinc acetate, 5mmol EDTA and 2g sodium hydroxide respectively, and dissolve them in the above mixed solution (pH value 10); after stirring, the resulting clear solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and distilled water was added to reach 80% of the reactor volume. After fully stirring, tighten the autoclave and put it in a constant temperature oven at 180°C for 12 hours. After the reaction was over, the reactor was taken out and allowed to cool naturally. Subsequently, the precipitate in the kettle was filtered, washed three times with distilled water, and then washed twice with absolute ethanol. Finally, the sample was dried in a vacuum oven at 60° C. for 4 hours to obtain ZnSe hollow microspheres. figure 1 For the X-ray diffraction spectrum of ZnSe hollow microspheres...

Embodiment 2

[0023] Prepare a mixed solution of distilled water and ethylene glycol with a volume ratio of 1:4, add a stoichiometric ratio of zinc salt and sodium selenite, control the concentration of NaOH to 0.8 mol / L (pH value is 12), and the molar ratio of EDTA and Zn The ratio is 1:1. After forming a colorless and transparent solution, transfer it to a stainless steel reactor with a polytetrafluoroethylene liner, add distilled water to 70% of the volume of the reactor, seal it, tighten it, and put it in a constant temperature oven at 140°C for 24 hours. After the reaction was over, the reactor was taken out and allowed to cool naturally. Subsequently, the precipitate in the kettle was filtered, washed three times with distilled water, and then washed twice with absolute ethanol. Finally, the sample was dried in a vacuum oven at 50° C. for 6 hours to obtain ZnSe hollow microspheres.

Embodiment 3

[0025] Prepare a mixed solution of distilled water and ethylene glycol with a volume ratio of 1:3, add a stoichiometric ratio of zinc salt and sodium selenite, control the concentration of NaOH to 0.9 mol / L (pH value is 12.4), and the molar ratio of EDTA and Zn The ratio is 3:1. After forming a colorless and transparent solution, transfer it to a stainless steel reactor with a polytetrafluoroethylene liner, add distilled water to 80% of the volume of the reactor, seal it, tighten it, and put it in a constant temperature oven at 200°C for 14 hours. After the reaction was over, the reactor was taken out and allowed to cool naturally. Subsequently, the precipitate in the kettle was filtered, washed three times with distilled water, and then washed twice with absolute ethanol. Finally, the sample was dried in a vacuum oven at 60° C. for 4 hours to obtain ZnSe hollow microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com