System and method for treating sewage at zero energy consumption by using ecological filter bed

A technology of sewage treatment system and filter bed, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of improper sludge suction treatment and disposal, operation and maintenance level It can achieve the effect of good water quality, low operating cost and less surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

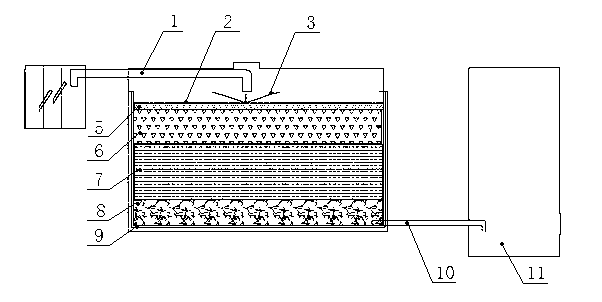

[0043] The ecological filter bed is as follows from bottom to top:

[0044] The anti-seepage layer 9 is a fiberglass anti-seepage isolation layer;

[0045] The water collecting layer 8 has a thickness of 250 mm and is composed of crushed stones with a diameter of about 0.5 to 10 mm;

[0046] The thickness of the composite percolation layer 7 is 1500mm, and it is filled with fly ash, sintered ceramic powder and river sand with a particle size of 0.1mm~1mm according to the ratio of 1:1:1;

[0047] The biological treatment layer 6 has a thickness of 300 mm, and is filled with sintered ceramic powder with a particle size of 1 mm to 5 mm after biological pre-film treatment;

[0048] The water distribution layer 5 has a thickness of 300mm and is composed of gravels with a diameter of about 10-50mm.

[0049] According to the present invention built according to the scheme of the first embodiment, its investment is only 1 / 5~1 / 7 of the conventional treatment process, and there is bas...

Embodiment 2

[0051]The ecological filter bed is as follows from bottom to top:

[0052] The anti-seepage layer 9 is an HDPE composite anti-seepage layer;

[0053] The water collection layer 8 has a thickness of 200mm and is composed of crushed stones with a diameter of about 0.5-10mm;

[0054] The thickness of the composite percolation layer 7 is 1500mm, and it is filled with fly ash with a particle size of 0.1mm~1mm, pulverized slag and river sand in a ratio of 1:1:2;

[0055] The biological treatment layer 6 has a thickness of 300 mm, and is filled with sintered ceramic powder with a particle size of 1 mm to 5 mm after biological pre-film treatment;

[0056] The water distribution layer 5 has a thickness of 300mm and is composed of gravels with a diameter of about 10-50mm.

[0057] According to the present invention built according to the second embodiment, its investment is only 1 / 5 of the conventional treatment process, and there is basically no operating cost. The operation effect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com