Stripping solution for chemical nickel-plated coating of cast aluminum piece and stripping method

A technology for electroless nickel plating and cast aluminum parts, applied in the field of deplating solution for electroless nickel plating of cast aluminum parts, can solve the problems of high cost of deplating, long operation time, complicated process, etc., and achieve simple manufacturing process and easy control , the effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

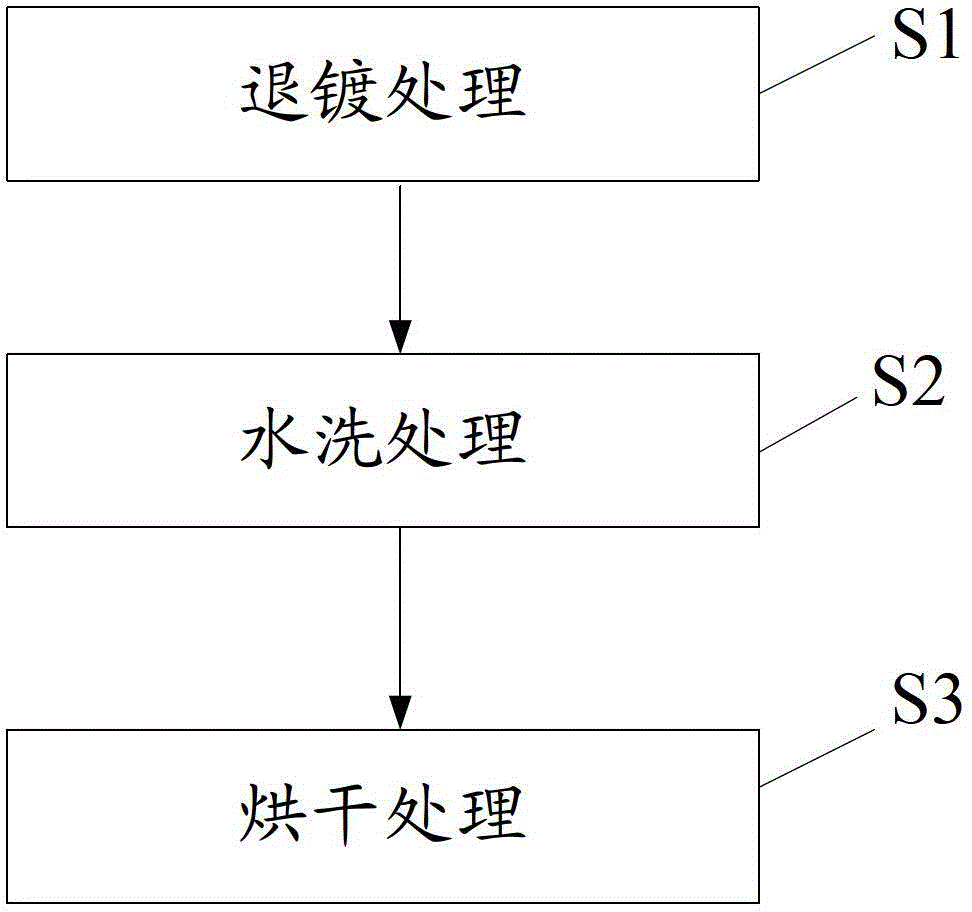

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the present invention. Such as figure 1 As shown, the deplating solution is firstly deplated in step S1. Specifically, a deplating solution comprising nitric acid, sodium m-nitrobenzenesulfonate, nickel powder, pure water, hydrofluoric acid, and sodium chloride is first mixed to prepare a deplating solution. Among them, hydrofluoric acid and nitric acid are used as oxidizing agents, and sodium chloride and nickel powder are used as corrosion inhibitors. The present invention has no specific requirements on the concentration and pH of the above-mentioned raw materials. Preferably, in the present embodiment, the nitric acid in the deplating solution is 600ml / L, the pure water is 300ml / L, the hydrofluoric acid is 100ml / L, the sodium chloride content is 10g / L, and sodium m-nitrobenzenesulfonate Content is 15g / L, and described nick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com