Inductive coupling plasma coil and plasma injection device

A plasma and inductive coupling technology, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of polluting wafers, increasing quartz window sputtering, plasma radial and azimuth inhomogeneity, etc., and achieve low radio frequency voltage , reduce the coil, reduce the effect of standing wave effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

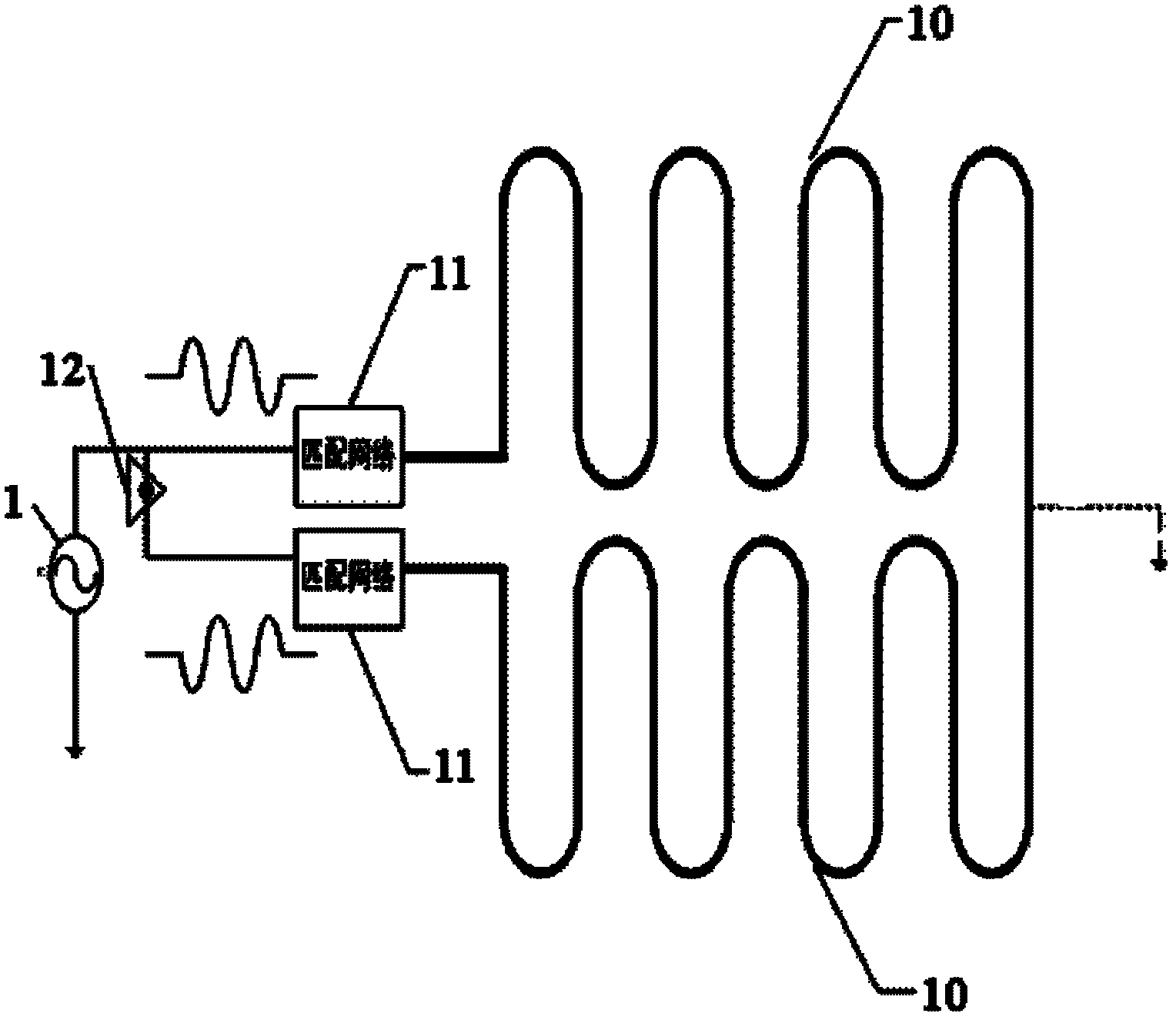

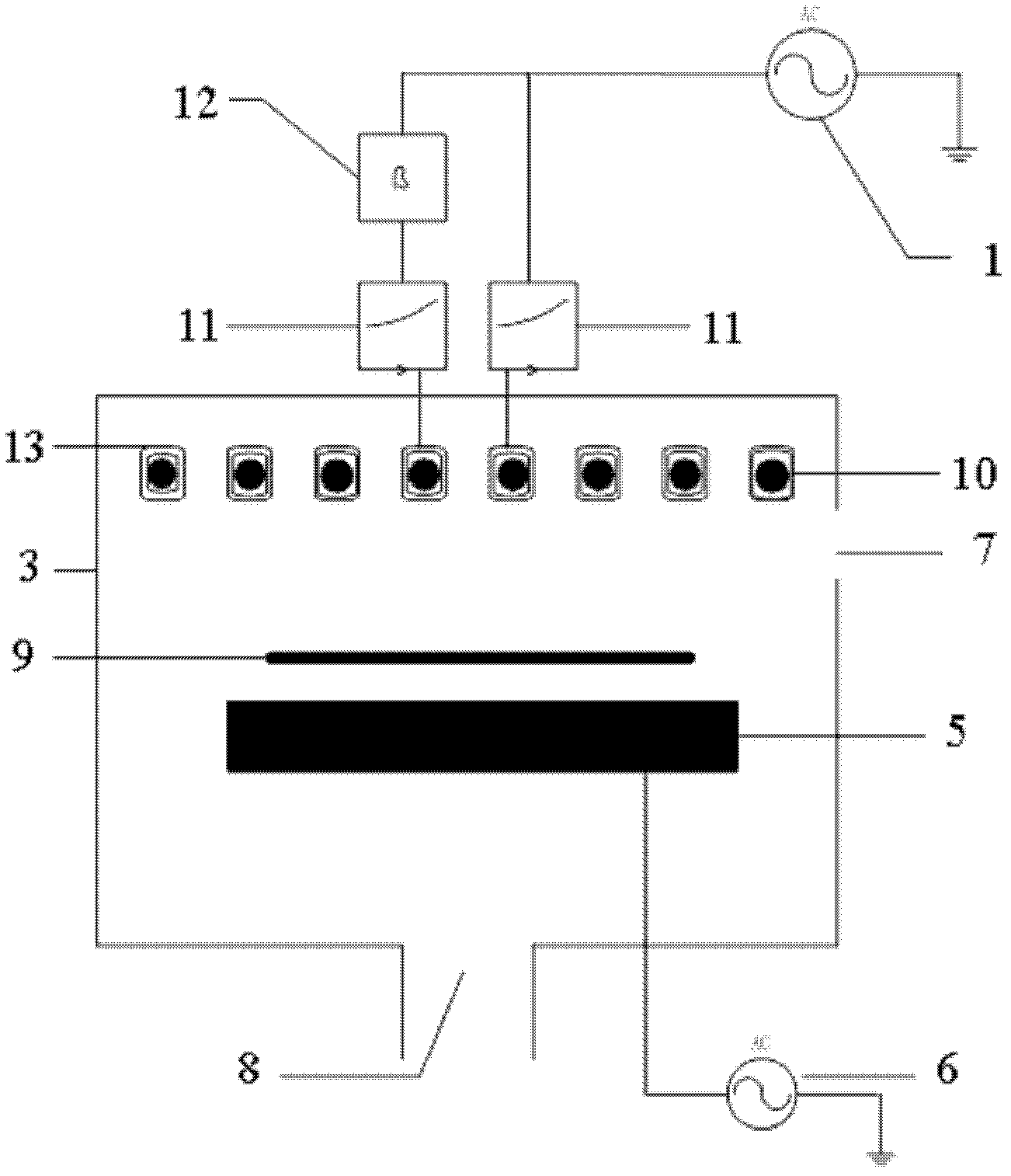

[0031] Such as figure 2 , image 3 As shown, the present invention provides an inductively coupled plasma coil 10 composed of two sets of folded radio frequency coils, one end of which is connected and the other end is not connected. The spatial structure of the two sets of radio frequency coils adopts a planar serpentine parallel connection, and the spatial distribution is strictly symmetrical, so that the direction of the radio frequency current at the same coil position is the same. The two sets of coils are made of hollow copper tubes with a radius of 1mm-10mm, which can be selected according to different requirements. In this embodiment, 5mm hollow copper tubes are used.

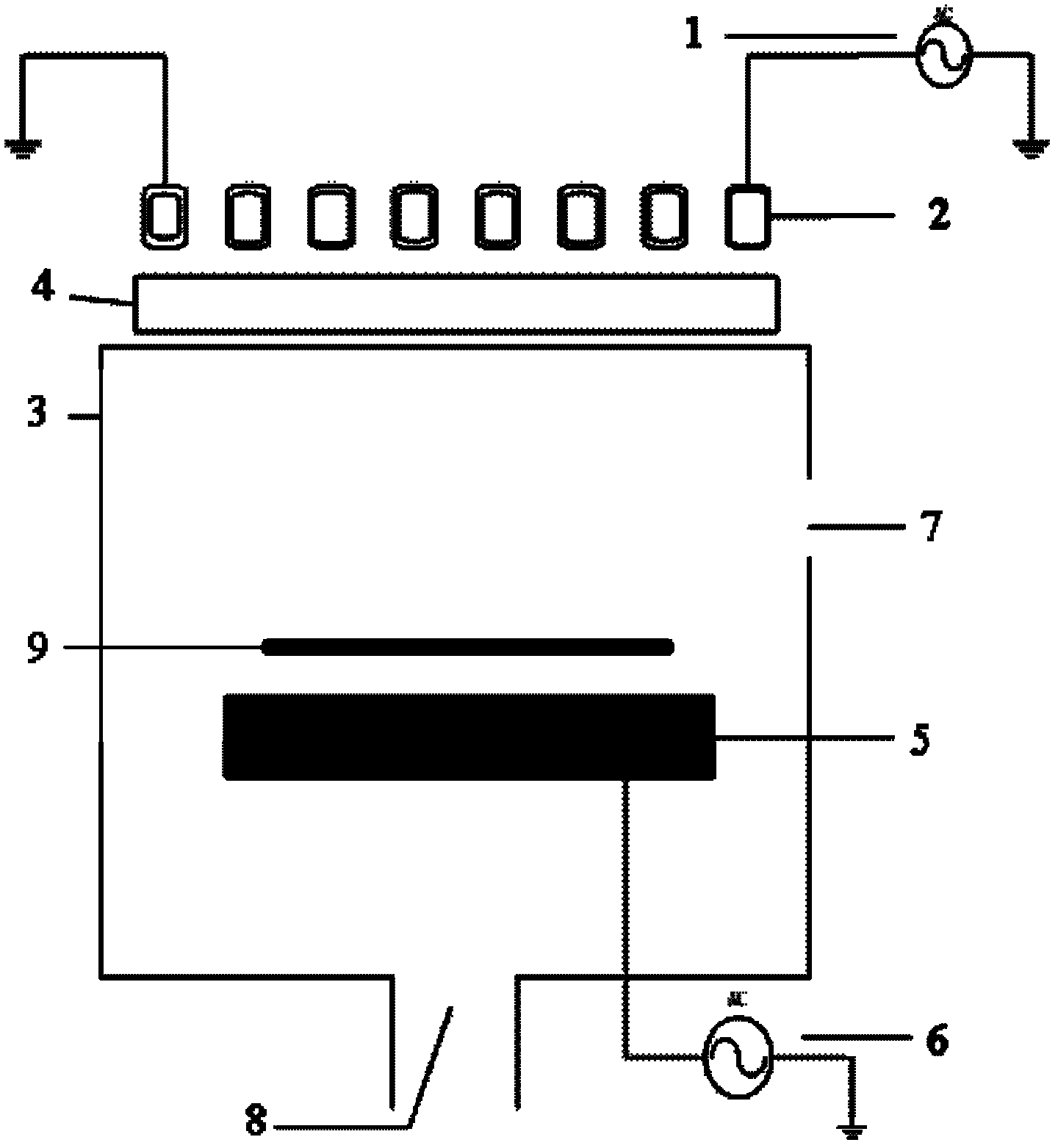

[0032] combine figure 2 , image 3 As shown, an inductively coupled plasma injection device provided by the present invention includes: plasma coil 10, two matching networks 11, phase shifter 12, quartz tube 13, first complementary power source 1, reaction chamber 3, base Seat 5 and second RF bias...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com