Large-specific-surface-area pure-phase TiO2 photocatalyst and preparation method and applications thereof

A technology with large specific surface area and photocatalyst, which can be used in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc. It can solve problems such as low quantum efficiency, achieve more active centers, and improve photocatalytic activity. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 3.83g of glycerol into 6mL of ethanol solution, stir evenly, add 1mL of titanyl sulfate, then stir until clear, called solution A. 2g LiAc·2H 2 O was dissolved in 10 mL (DMF:HAc=4:6) mixed solution, called solution B. At room temperature, add solution B to solution A, stir well until the solution is evenly mixed, then add 3mL of anhydrous diethyl ether, stir evenly, transfer to a 100mL hydrothermal kettle, keep at 110°C for 48h, and then naturally cool to room temperature; After centrifugation and washing with deionized water and ethanol three times each, dry in a vacuum constant temperature oven at 80 °C for 12 h to obtain a large specific surface area pure phase TiO 2 catalyst of light.

Embodiment 2

[0028] Add 3.83g of glycerol into 6mL of ethanol solution, stir evenly, add 3mL of titanyl sulfate, then stir until clear, called solution A. 2g LiAc·2H 2 O was dissolved in 10 mL (DMF:HAc=4:6) mixed solution, called solution B. At room temperature, add solution B to solution A, stir well until the solution is evenly mixed, then add 3mL of anhydrous diethyl ether, stir evenly, transfer to a 100mL hydrothermal kettle, keep at 110°C for 48h, and then naturally cool to room temperature; After centrifugation and washing with deionized water and ethanol three times each, dry in a vacuum constant temperature oven at 80 °C for 12 h to obtain a large specific surface area pure phase TiO 2 catalyst of light.

Embodiment 3

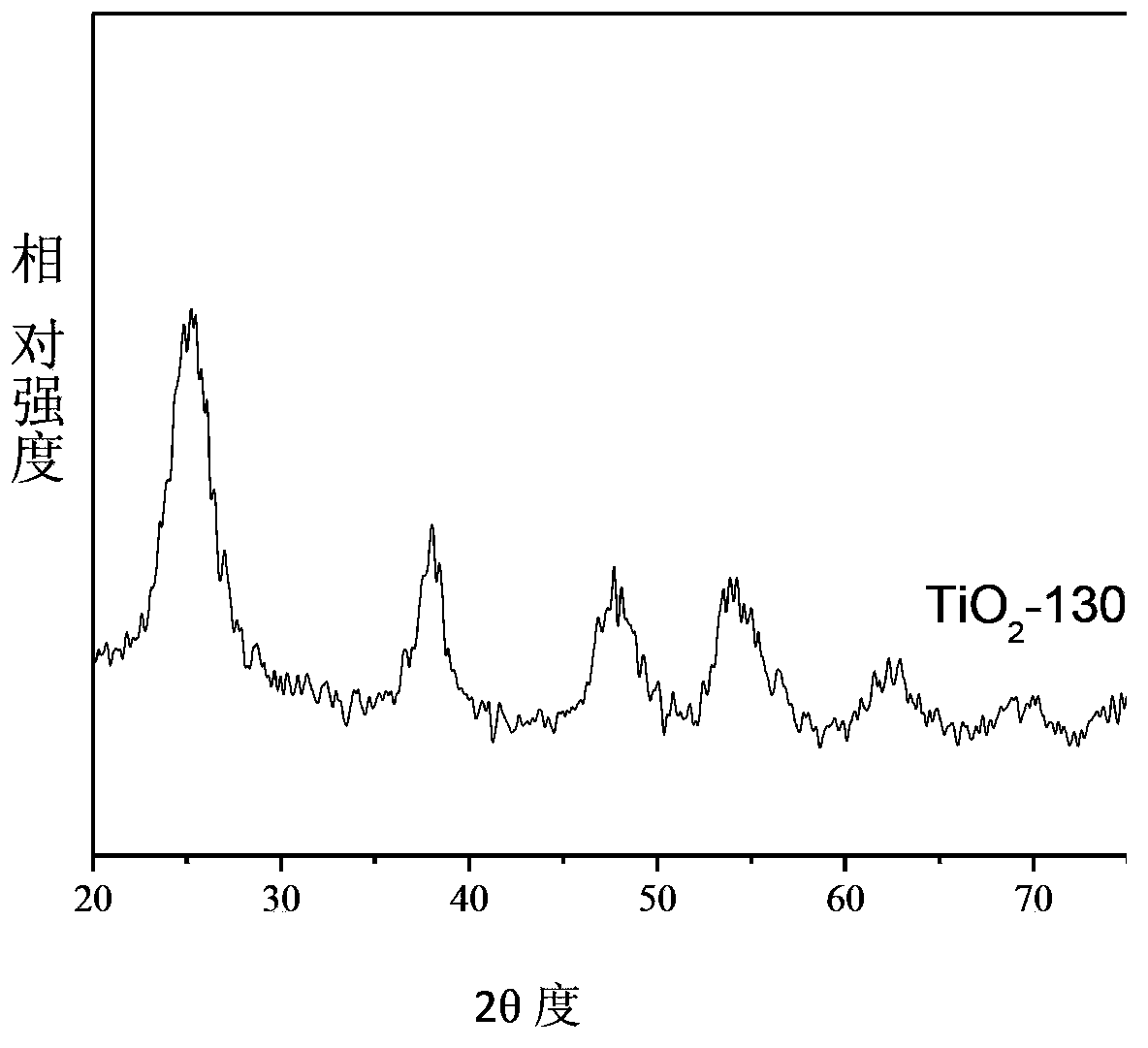

[0030] Add 3.83g of glycerol into 6mL of ethanol solution, stir evenly, then add 3mL of titanyl sulfate, then stir until clear, called solution A. 3g LiAc·2H 2 O was dissolved in 10 mL (DMF:HAc=4:6) mixed solution, called solution B. At room temperature, add solution B to solution A, stir well until the solution is evenly mixed, then add 3mL of anhydrous diethyl ether, stir evenly, transfer to a 100mL hydrothermal kettle, keep at 130°C for 48h, and then naturally cool to room temperature; After centrifugation and washing with deionized water and ethanol three times each, dry in a vacuum oven at 80°C for 12 hours to obtain a pure phase of TiO with a large specific surface area. 2 catalyst of light

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com