High-viscosity composite film for flexible electronic packaging application, and its processing method

A technology of electronic packaging and processing method, which is applied in the field of high-viscosity composite film for flexible electronic packaging applications and its processing, can solve the problems of low safety and immature technology, and achieves improved surface energy, good dimensional stability and performance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

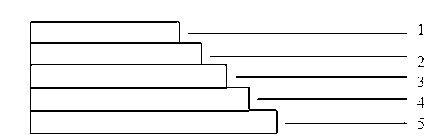

[0016] like figure 1 As shown, the high-viscosity composite film for electronic applications of the present invention comprises a polyester film substrate layer 1, a first adhesive layer 2, an adhesion promoter layer 3, a second adhesive layer 4 and a heat-sealing layer 5 from the top layer to the bottom layer.

[0017] The processing method of this high-viscosity composite film comprises the following steps:

[0018] 1) Using polyester film as the substrate, using plasma chemical modification technology to improve the surface tension of polyester film;

[0019] 2) Coat a layer of polymer solution under the modified polyester film as an intermediate adhesive, and after drying, compound with the melt-modified polyolefin resin of the first casting technology to form an adhesion-promoting layer;

[0020] 3) After cooling and trimming on-line, another layer of polymer solution is coated under the adhesion-promoting layer as an intermediate adhesive, and after drying, it is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com