Preparation method of layered chemical manganese dioxide

A manganese dioxide and chemical technology, applied in the field of preparation of layered chemical manganese dioxide, can solve the problems of unstable reaction, expensive raw materials and high production cost, and achieve the effects of easy availability of raw materials, mild reaction conditions and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

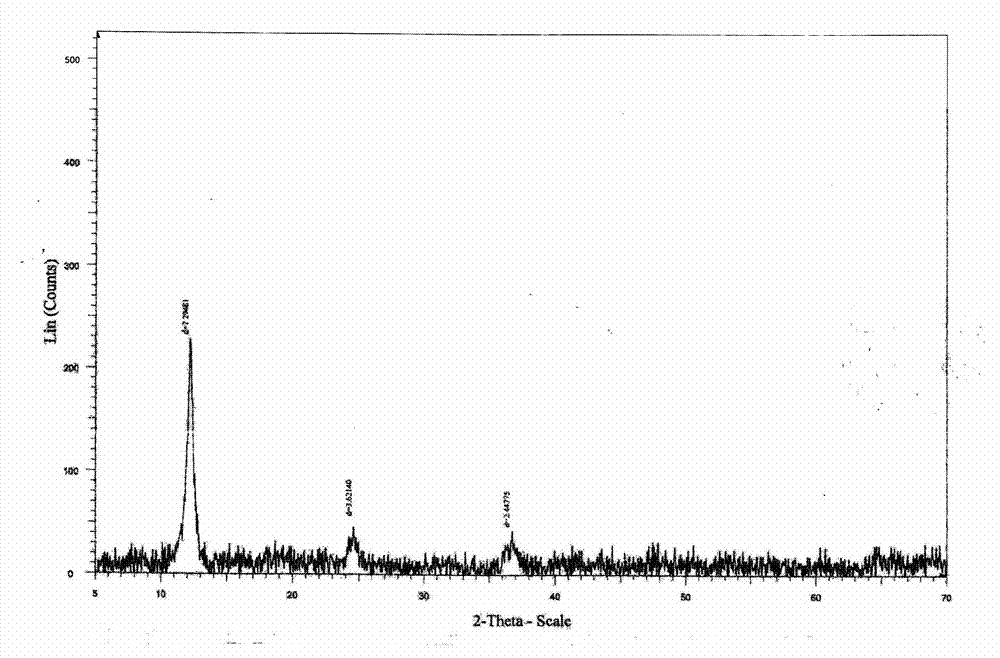

Image

Examples

Embodiment 1

[0012] Mix 45g of electrolytic manganese dioxide powder with an average particle size of 76μm and a manganese content of 61.11% with 66.8g of solid sodium hydroxide, place it in a box-type resistance furnace and bake at 400°C for 5 hours. The roasted product sodium manganate was leached with tap water at a ratio of liquid to solid mass ratio of 3:1, the leaching temperature was 25°C, and the leaching time was 8 hours to obtain a sodium manganate solution for later use.

[0013] Stir the above sodium manganate solution and heat it up to 75°C, then add 250mL of manganese sulfate solution with a manganese content of 50g / L dropwise into the sodium manganate solution, the addition time is 5 minutes, and keep it warm for 3 hours after the addition is complete. Filter, wash, dry at 120°C, and pulverize to obtain a layered chemical manganese dioxide product. The product contains 78.45% manganese dioxide, 5.52% sodium content, an average particle size of 3.54 μm, and a specific surface ...

Embodiment 2

[0015] Mix 46g of chemical manganese dioxide powder with an average particle size of 45μm and a manganese content of 59.8% with 100g of solid sodium hydroxide, and place it in a box-type resistance furnace for calcination at 500°C for 10 hours. The roasted product sodium manganate is leached with tap water according to the liquid-solid mass ratio of 6:1, the leaching temperature is 40°C, and the leaching time is 6 hours to obtain a sodium manganate solution, which is set aside.

[0016] Stir the above sodium manganate solution and raise the temperature to 25°C, then add 50mL of manganese nitrate solution with a manganese content of 250g / L dropwise into the sodium manganate solution for 50 minutes, and keep warm for 15 hours after the addition. Filter, wash, dry at 120°C, and pulverize to obtain a layered chemical manganese dioxide product. The product contains 77.56% manganese dioxide, 5.82% sodium content, an average particle size of 3.85 μm, and a specific surface area of 2...

Embodiment 3

[0018] Mix 45g of electrolytic manganese dioxide powder with an average particle size of 76μm and a manganese content of 61.11% with 200g of solid sodium hydroxide, place it in a box-type resistance furnace and bake at 550°C for 15 hours. The roasted product sodium manganate was leached with deionized water according to the liquid-solid mass ratio of 10:1, the leaching temperature was 30°C, and the leaching time was 0.5 hours to obtain a sodium manganate solution, which was set aside.

[0019] Stir the above sodium manganate solution to heat up to 80°C, then add 155mL of manganese sulfate solution with a manganese content of 80g / L dropwise into the sodium manganate solution, the addition time is 100 minutes, and keep warm for 12 hours after the addition is complete. Filter, wash, dry at 120°C, and pulverize to obtain a layered chemical manganese dioxide product. The product contains 79.33% manganese dioxide, 6.50% sodium content, an average particle size of 2.75 μm, and a speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com